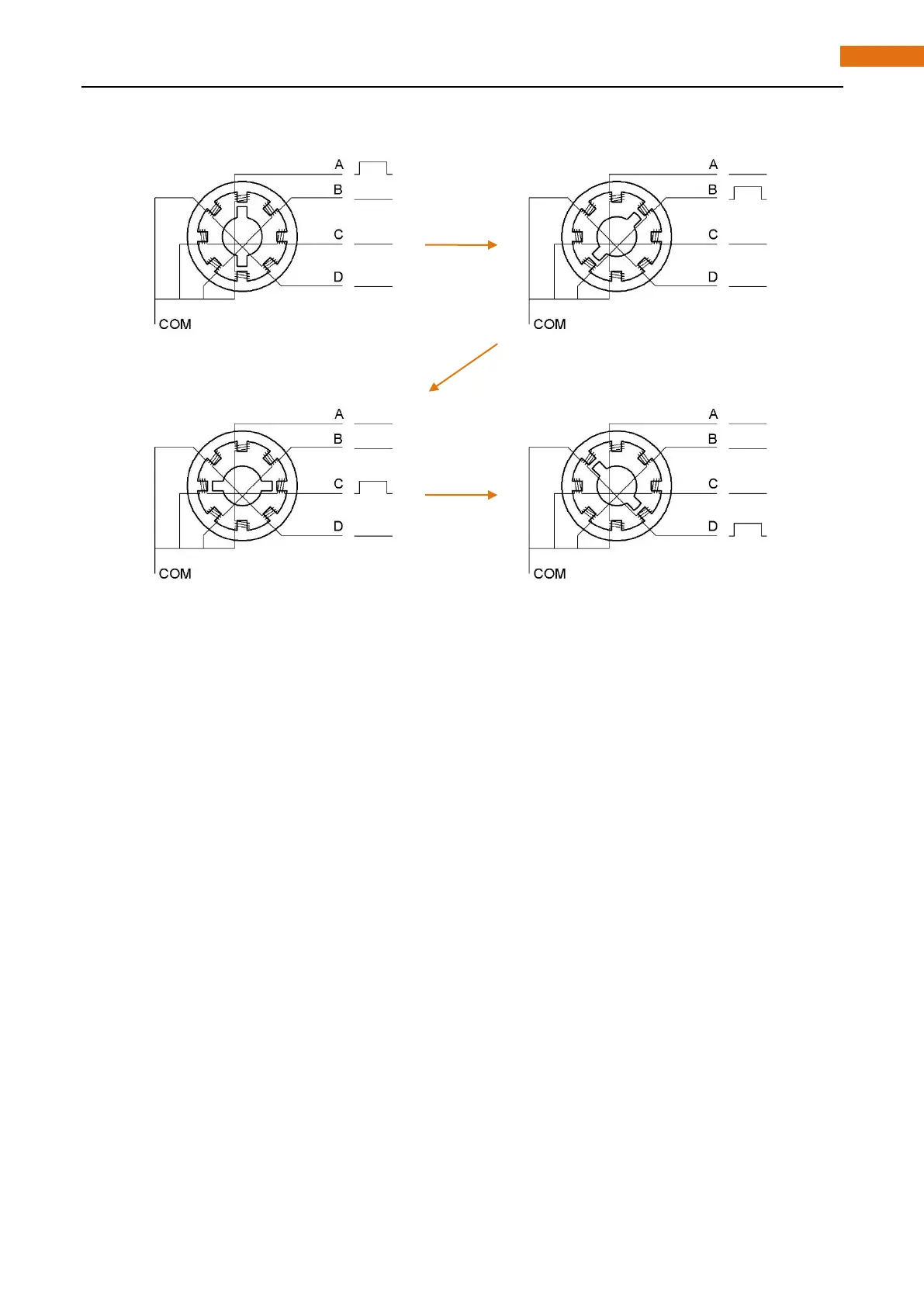

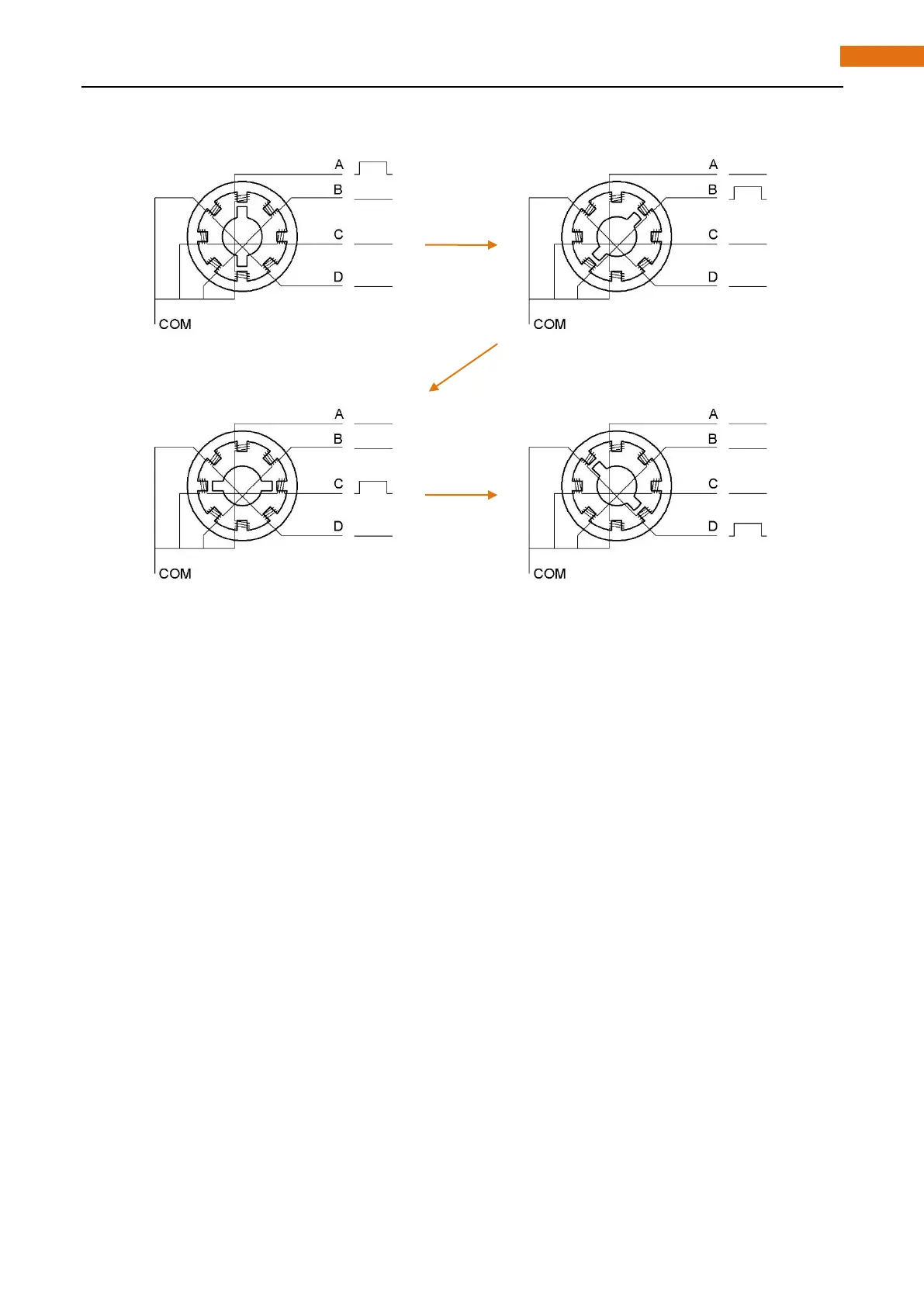

A common driving process is as follows:

In the course above, the stepping motor rotates a certain angle once, which is called a step. By controlling

the number of rotation steps, you can control the stepping motor rotation angle. By controlling the time

between two steps, you can control the stepping motor rotation speed. When rotating clockwise, the order

of coil powered on is: ABCDA…… . And the rotor will rotate in accordance with the order, step by

step down, called four steps four pats. If the coils is powered on in the reverse order, DCBAD… ,

the rotor will rotate in anti-clockwise direction.

Stepping motor has other control methods, such as connect A phase, then connect A B phase, the stator will

be located in the middle of the A B, only a half-step. This way can improve the stability of stepping motor,

and reduce noise, the sequence of coil powered on is: AABBBCCCDDDAA……, the rotor

will rotate in accordance with the order, a half step by a half step, called four step eight pat. Equally, if the coil

is powered on in reverse order, the stepping motor will rotate in reverse rotation.

The stator of stepping motor we use has 32 magnetic poles, so a circle needs 32 steps. The output shaft of

the stepping motor is connected with a reduction gear set, and the reduction ratio is 1/64. So the final output

shaft rotates a circle requiring a 32*64=2048 step.

Loading...

Loading...