35 SERIES GAS FRYERS

CHAPTER 5: PREVENTIVE MAINTENANCE

5-5

5.3 Semi-Annual Checks and Service

Check Burner Manifold Pressure

WARNING

This task should be performed by qualified service personnel only.

1. Ensure that the gas valve knob is in the OFF position.

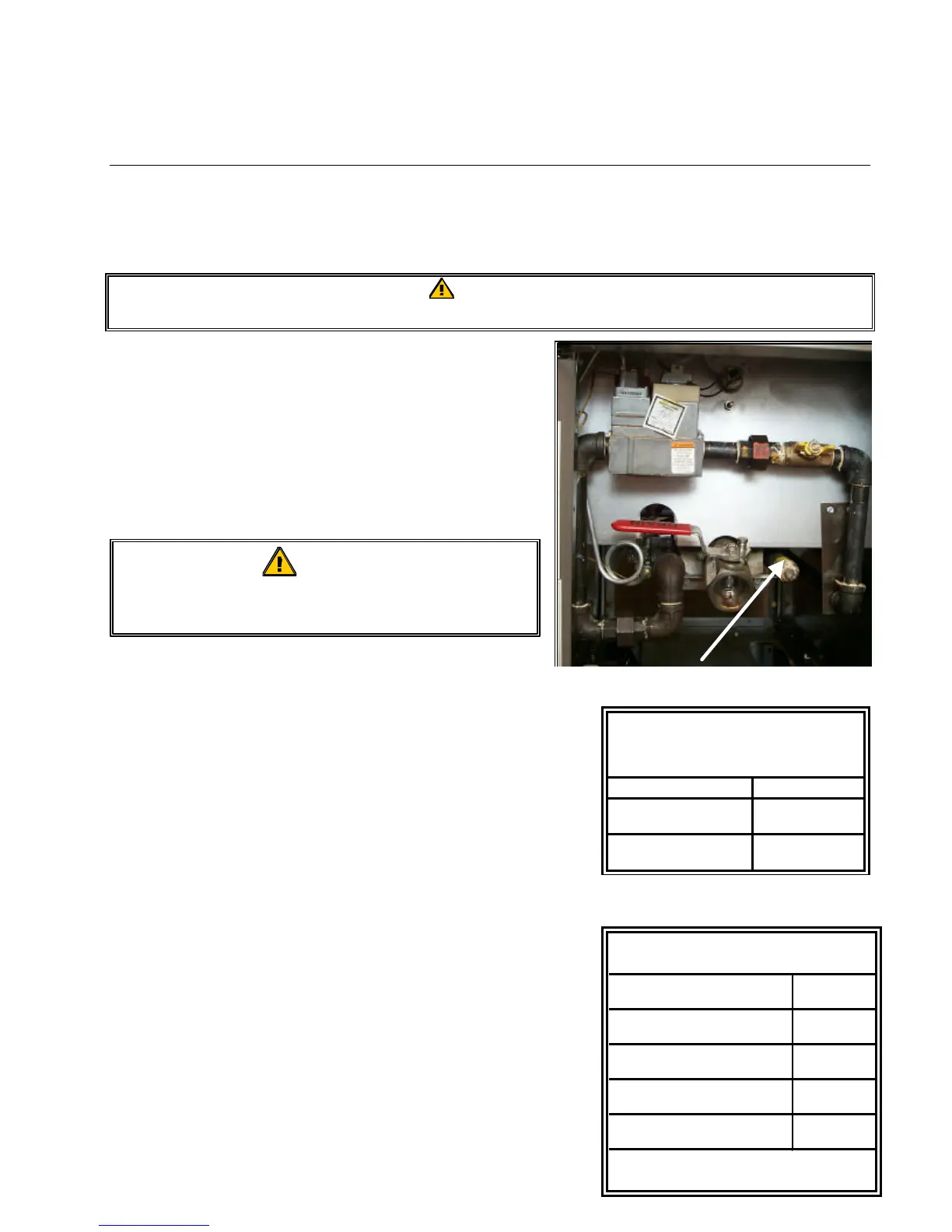

2. Remove the pressure tap plug from burner manifold.

(see photo).

3. Insert the fitting for a gas-pressure measuring device

into the pressure tap hole.

4. Place the gas valve in the PILOT position and light. When the

burner lights and continues to burn, note gas pressure reading

and compare to the accompanying tables.

5. To adjust burner gas pressure, remove the cap from the gas

valve regulator adjustment screw.

6. Increase the setting on the thermostat until the burner comes on.

7. Monitor the gas pressure reading on the man-ometer or

pressure gauge.

8. Adjust the gas valve regulator adjustment screw to obtain the

prescribed pressure. See the Rating Plate. Turning the screw

clockwise increases pressure, counterclockwise decreases

pressure.

A manometer or water column pressure gauge

meter is connected to the manifold here.

Gas

(mbar)

Natural Gas Lacq

(G20) under 20 mbar

9

Natural Gas Groningue *

(G25) under 25 mbar

11

Natural Gas Groningue

(G20) under 20 mbar

11

Propane

(G31) under 37 or 50 mbar

22.5

CE Standard

Burner Manifold Gas Pressures

* Belgian specifications on 2-6

WARNING

The frypot must be filled with shortening or

water during this procedure.

Non-CE Standard

Burner Manifold Gas

Pressures

Gas Pressure

Natural 4.0" W.C.

0.73 kPa

LP 8.25" W.C.

2.05 kPa

Loading...

Loading...