700-Bubbler-Man Rev 12 13 Feb 2020

Page 42/51

Appendix B TROUBLESHOOTING GUIDE

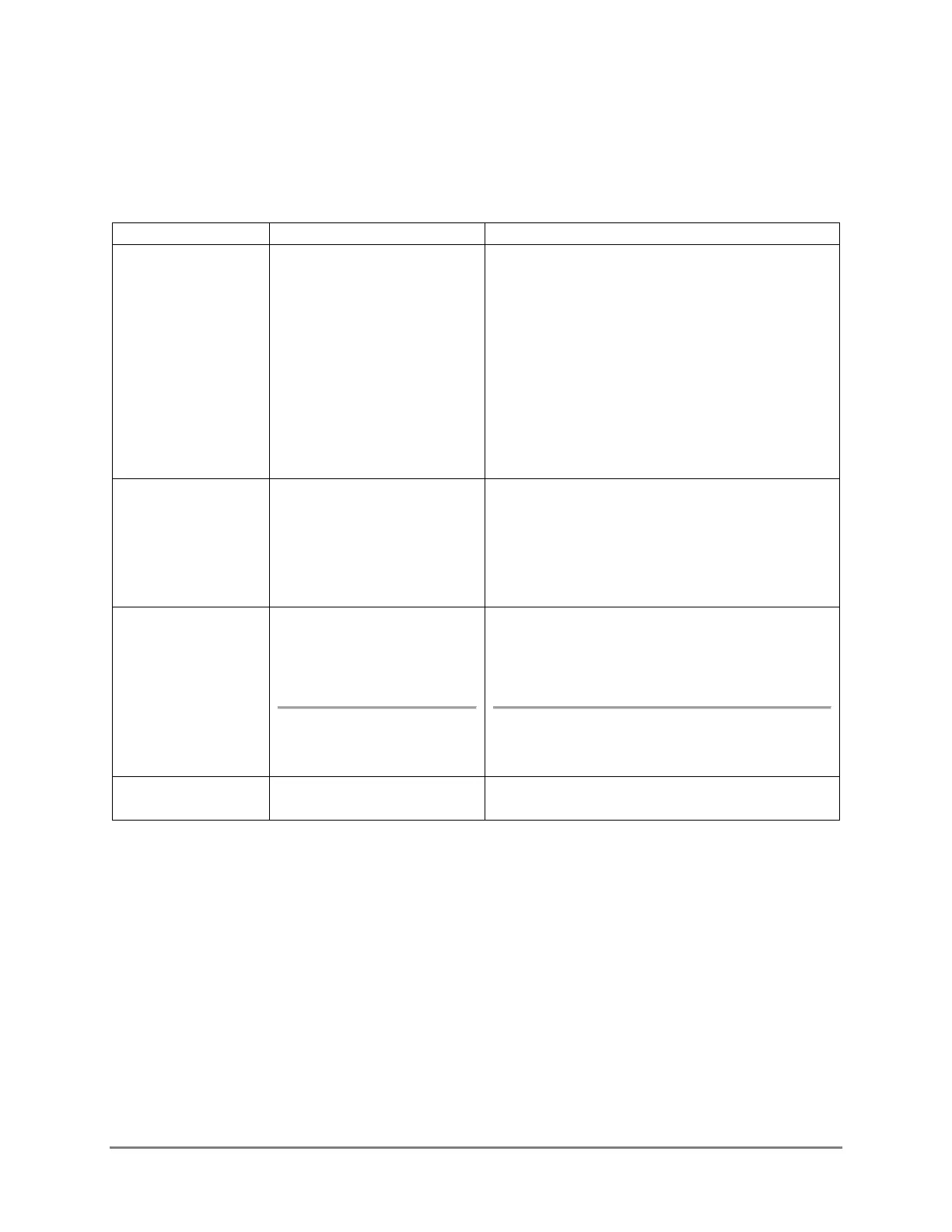

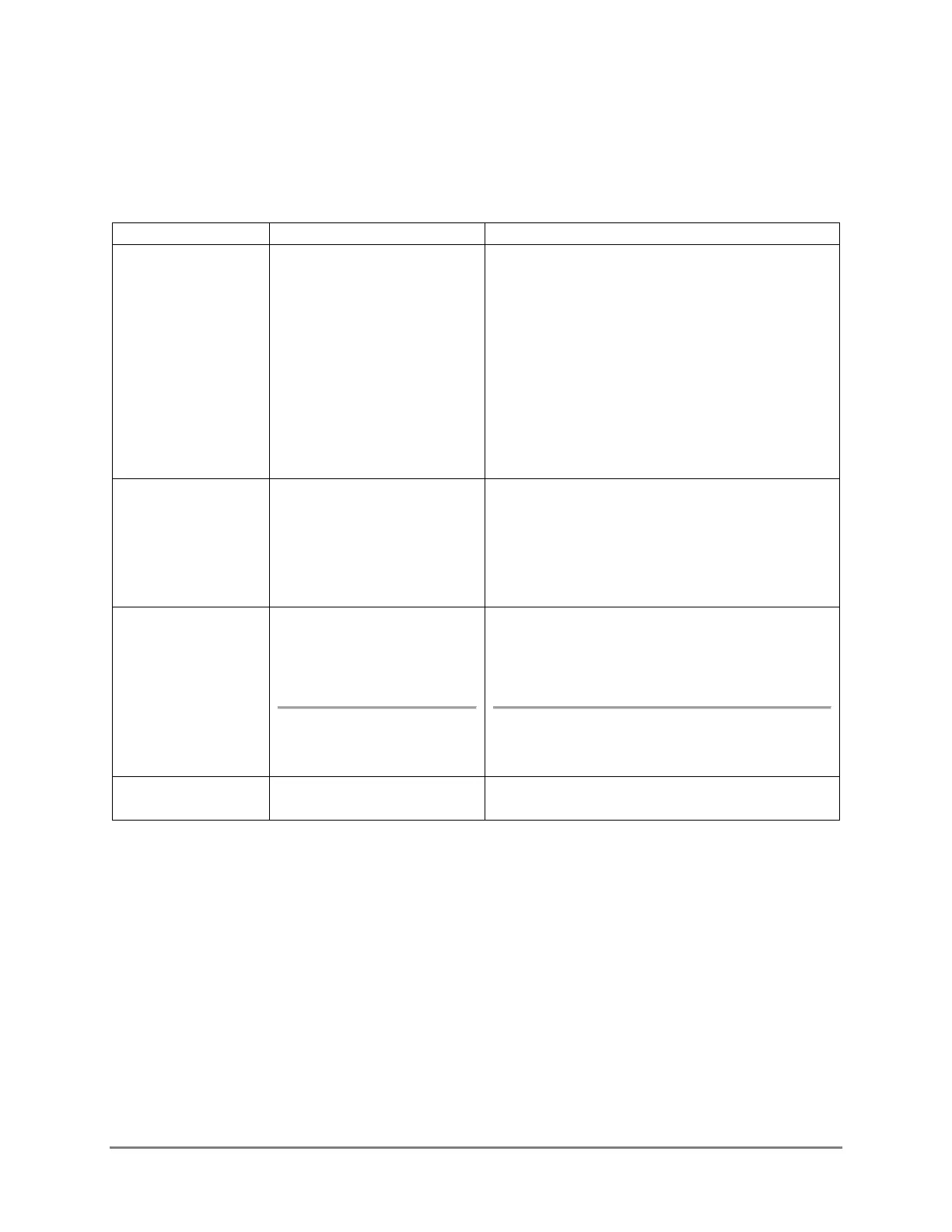

B.1 MECHANICAL INDICATORS

dropping/excessive

pump operation

System leak (either internal

or at Bubbler line

connections)

1) Ensure orifice line is correctly seated and

tightly attached at all connection points. All

fittings should be attached using Teflon tape

to maintain tight seal.

2) Inspect orifice line for splices. Replace

spliced line.

3) If Bubbler line connections are correct, an

internal leak is indicated. Contact FTS Support

running

1) Ensure Bubbler has a direct power source.

It cannot be fully powered through the

Datalogger’s SDI port (section 2.6.2).

2) Check power connections (including solar

panel, if using).

3) Check battery (replace if necessary).

A) Erroneous offset value

B) Blocked orifice line

1) Set Stage directly by entering the staff

gauge value (if known); or

2) Poll the sensor. Refer to Section 4.6.2.

1) Conduct a purge.

2) Ensure orifice is free from larger

obstructions/blockages.

Slight pause in

bubble release

No action required. This is normal operation.

B.2 MEASUREMENT VALUE FAULT INDICATOR

A fault is indicated if The M or M1 command returns a value of -99999.0.

If after 45 seconds of purging, the line cannot be cleared, and the tank pressure is greater than

35 psi, a LINE_HIGH will be indicated in the status screen and the compressor will stop. The M and

M1 commands will continue to be sent but will return values of -99999.0. The unit will continue to

attempt to bubble (the solenoid will continue to open and close) in the event the blockage does get

cleared and normal operations can resume.

Refer to LINE_HIGH Fault in Section B3 for troubleshooting.

Loading...

Loading...