700-Bubbler-Man Rev 12 13 Feb 2020

Page 44/51

DATA INDICATORS (con’t)

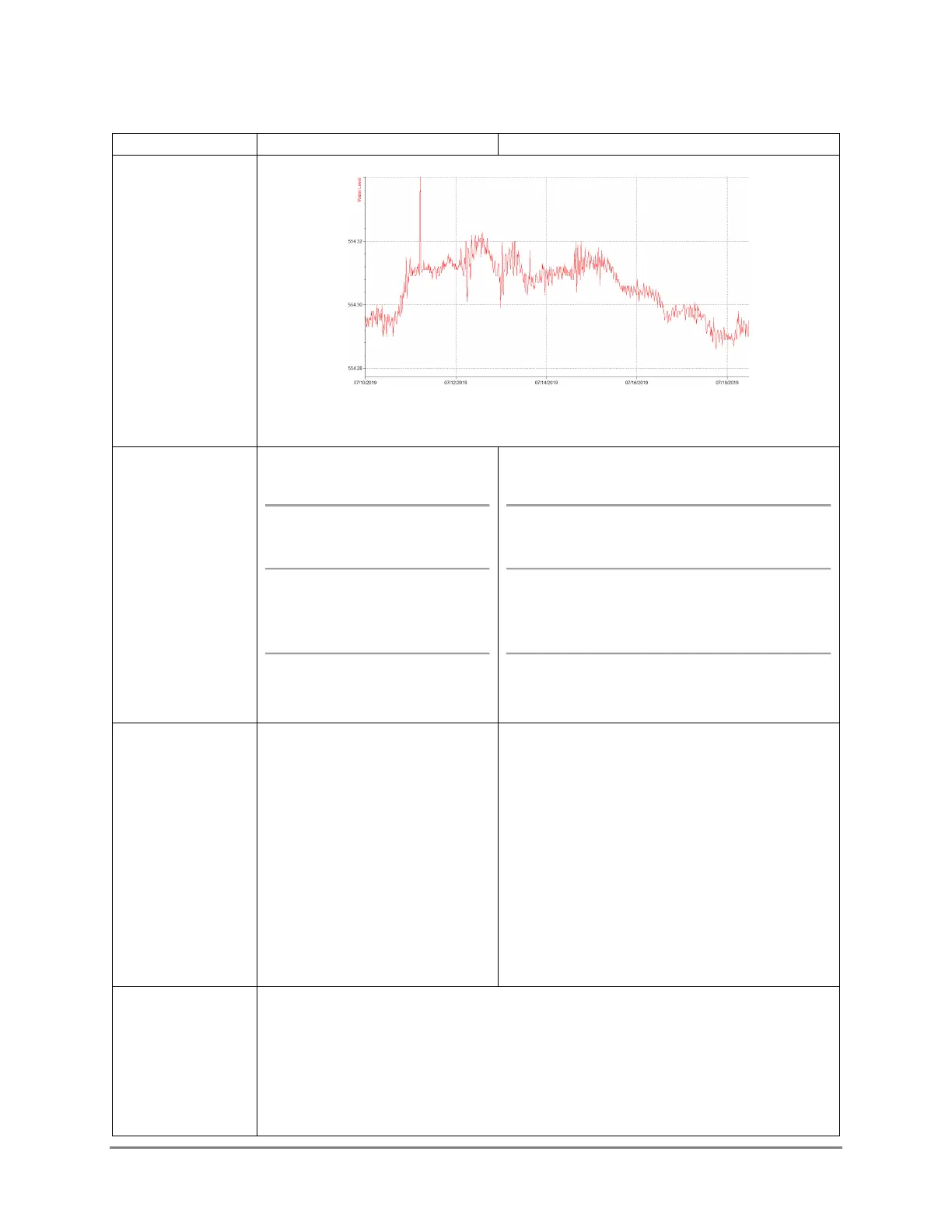

Data painting

(saw tooth graph)

Figure B-1: Example of data painting

termination

B) Orifice line termination not

secure (moving in the flow)

C) Moisture in orifice line

D) Samples are too frequent -

dampening is required

Ensure the orifice line termination is free

from silt/obstructions.

Ensure the orifice line termination point is

secured to prevent any movement.

Remove any catenaries along the orifice line

run (moisture can accumulate in lower

points along the line’s run).

Increase the sampling period (Averaging

Duration) with the XSP command (see

Data spikes

Air intake path is restricted

1) Ensure there are no blockages in the air

intake path, including possible blocked

desiccant inlet vent

2) Remove any check valves or similar

restricting attachments on the air inlet path

3) Ensure each Bubbler has a dedicated

desiccator and air intake path (i.e. do not

run multiple Bubblers on the same

desiccator)

For the curious: The atmospheric reference for the pressure transducer is

based on the air pressure from the air inlet. A temporary difference in the

atmospheric reference occurs when the air inlet path is plugged or restricted

(such as with check valves), this results in a temporary difference in the

atmospheric reference until pressure equalizes. These periods will be

displayed as data spikes which correspond to tank top ups (for a blocked

valve) or when the check valves engage after the compressor stops.

Loading...

Loading...