12 Rev 007, 04/12

© SP Scientific 2012

Now that the unit has its cooling medium, it is time to tie the hook the unit up to your

process. But first:

Press the I/O button to shut off the pump. 1.

Move the rocker switch to the EMO (O) position. 2.

Replace panels. 3.

Optional High Pressure Bypass Hook-up

The high-pressure bypass allows the user to control the pressure of the process fluid

going to the application. This can be particularly useful if an application is sensitive to

pressure such as a glass jacketed reaction vessel.

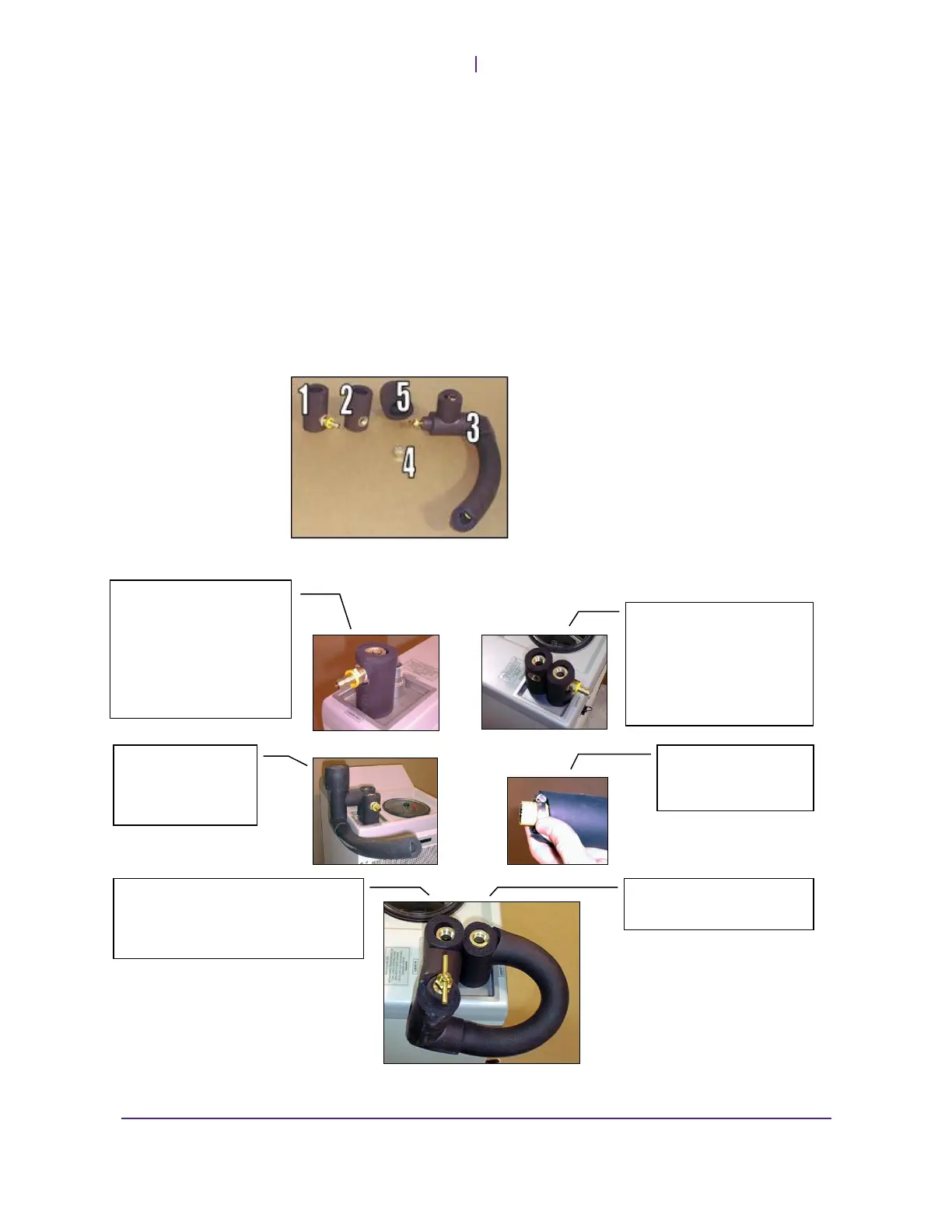

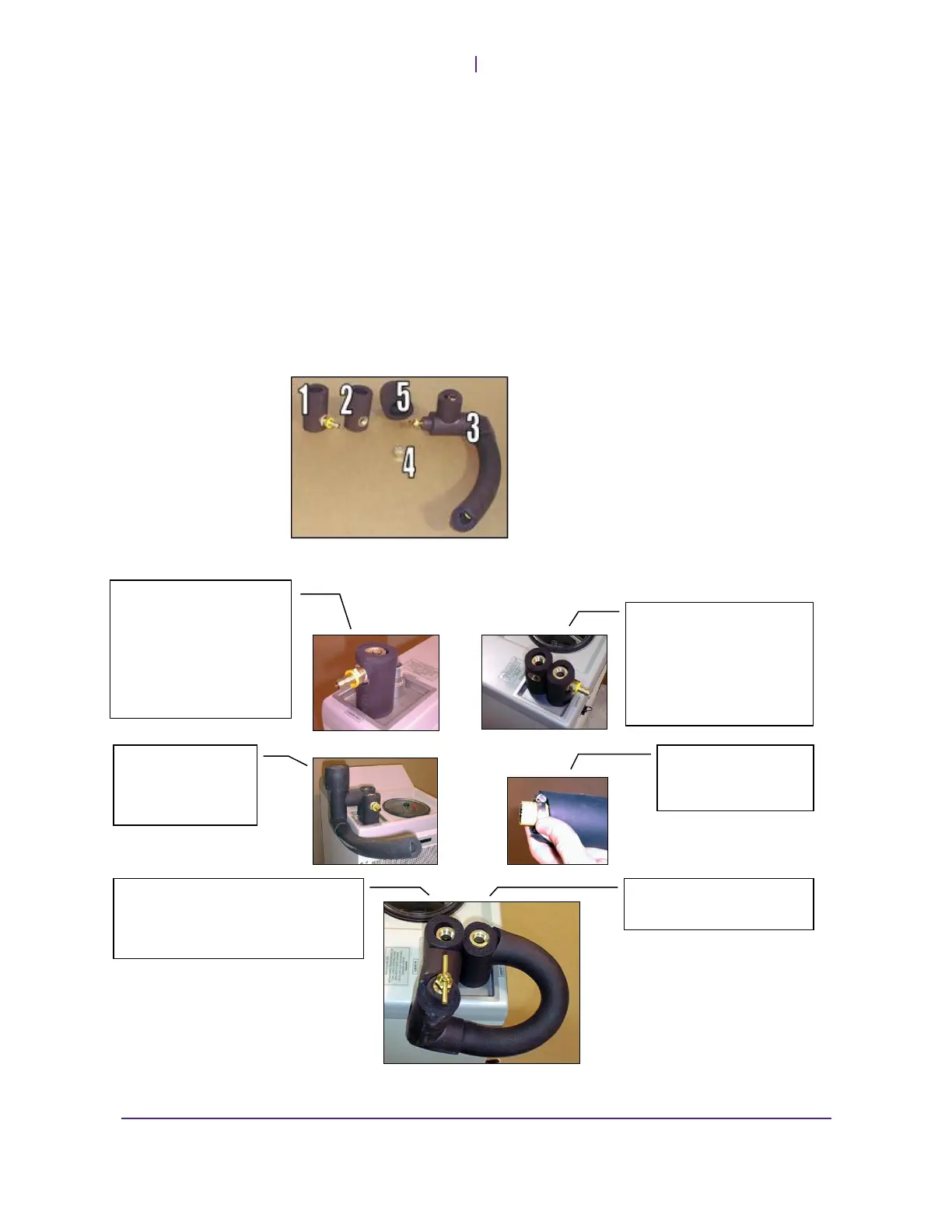

1) Thread Part 1 onto the

process fluid output and

tighten. The barb should face

toward the back of the unit.

Long side of insulation goes

down. (remember to use pipe

thread sealant on all metal to

metal connections)

2) Thread Part 2 onto the

process fluid input and tighten.

The opening should point

toward right-hand side of the

machine (operators right when

looking at the control panel).

Long side of insulation goes

Part 2 and tighten so

that the hose points

toward the back of the

4) Pull insulation on Part

3’s hose back and slide

the hose clamp (Part 4)

5) Slide the hose from Part 3 all the way

onto the hose barb on Part 1. Position the

hose clamp (Part 4) and tighten so that

the hose is firmly gripped between the

hose barb and the hose clamp.

Connect process fluid lines to

Parts 1 and 2 as per the

Loading...

Loading...