36

Chapter 11 TROUBLESHOOTING

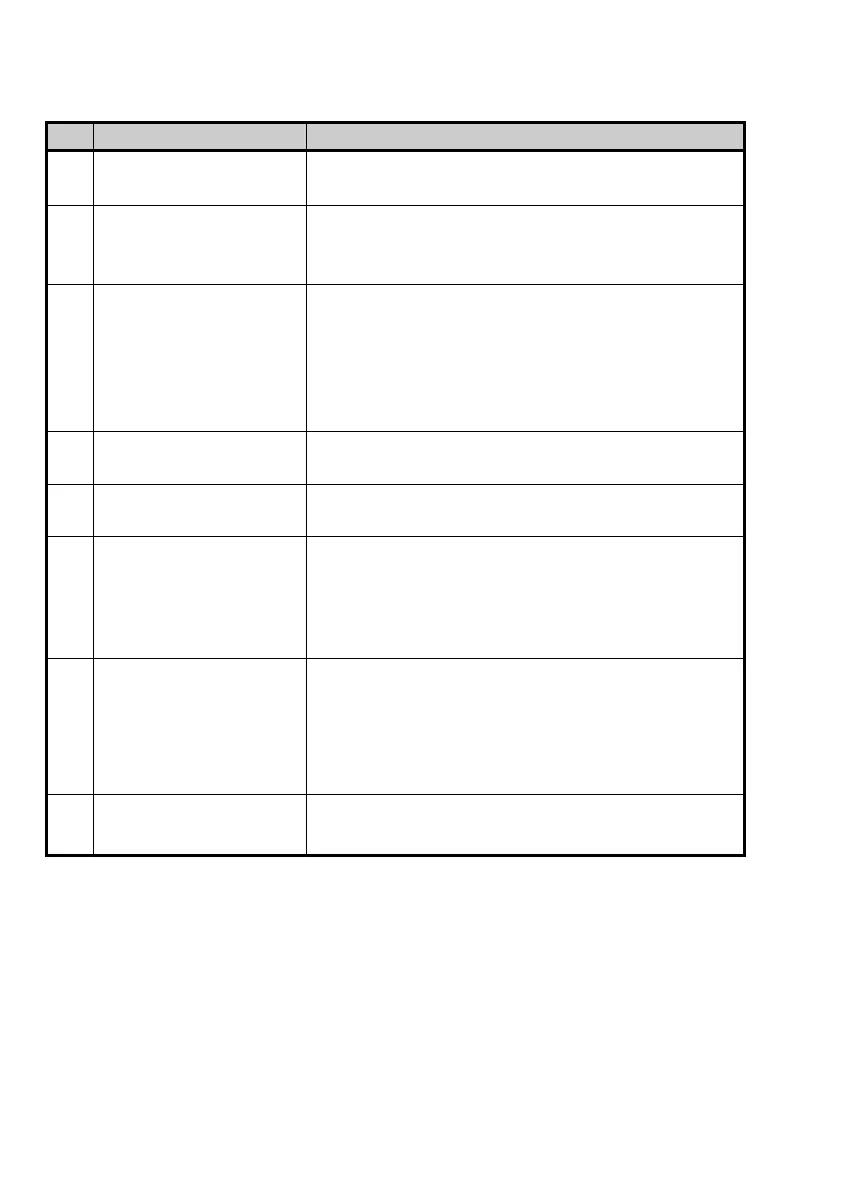

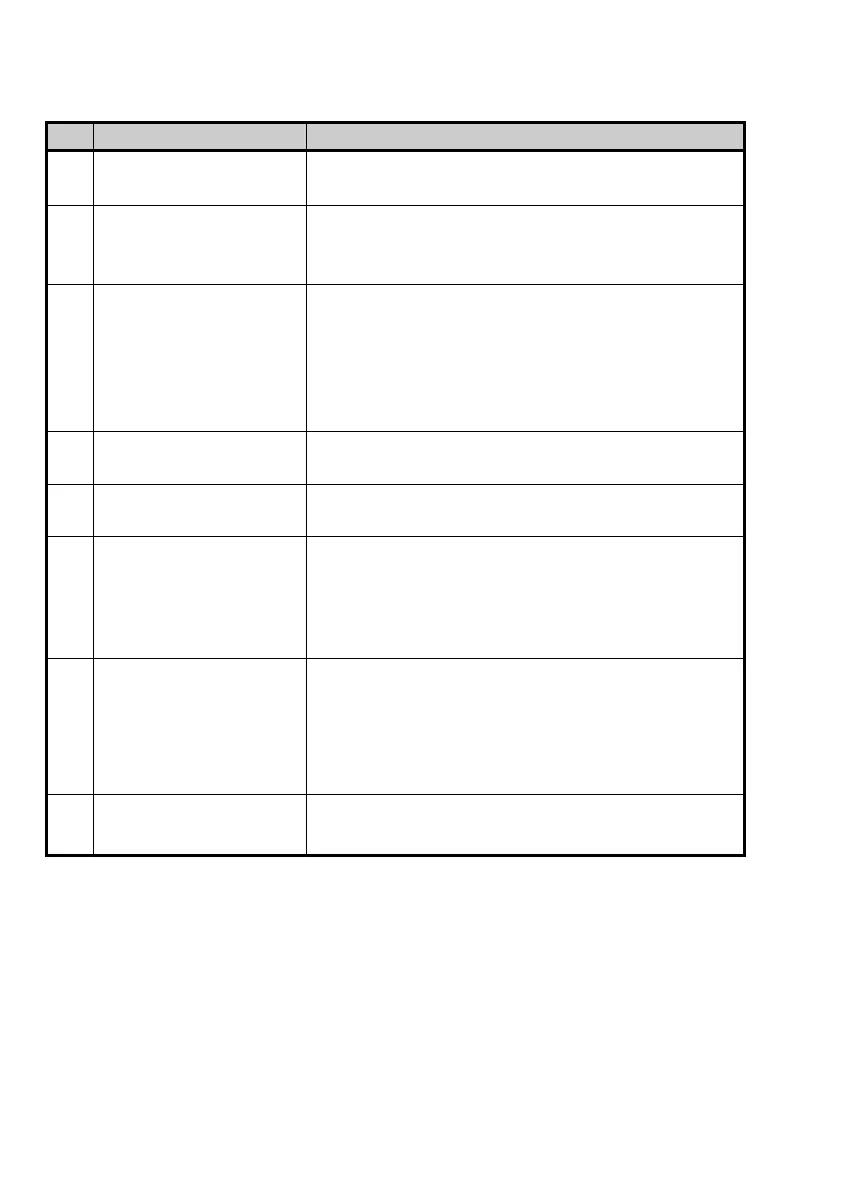

If any problem or error occurs during DeviceNet communication, follow the troubleshooting procedures given

below.

No Phenomenon/Symptom Probable Causes

1

None of the LEDs on the

option would light.

• No 24 VDC power supply is connected to this option.

• The option is faulty.

2

er4

alarm cannot be reset

(The MS LED lights in red).

• The option is not properly mounted.

• The option connection cable is not connected.

• The option is faulty.

3

The NS LED lights in red.

(

er5

alarm cannot be reset.)

• The same node address is double assigned in DeviceNet.

• There is a mismatch in baud (data) rate.

• The network power (24 V) is not properly supplied.

• Cabling for DeviceNet communications is not properly done.

• The inverter and the option have not been powered OFF and

then ON after modifying the DIP switch settings.

4

The NS LED blinks in red.

(

er5

alarm has occurred.)

• The cable was broken during communication.

• The I/O scan interval is too short.

5 The NS LED would not light.

• The node address for the option is improper.

• The cable for DeviceNet communications was broken.

6

The NS LED keeps blinking in

green and does not come to

stay on in green.

• The master does not request a connection.

• The I/O scan interval has been set to be too short at the start of

communication.

• The I/O area is invalidly mapped.

• There is no I/O connection.

7

Even though the NS LED

lights in green, the settings for

run command or speed

command cannot be

validated.

• Neither NetCtrl nor NetRef is set to "1."

• On the inverter, the higher-priority run command or speed

command is enabled.

• There is a mistake in the selection of I/O Assembly Instances.

• The inverter and the option have not been powered OFF and

then ON after modifying the o31 data.

8

Although the speed command

has been validated, the actual

speed is different from it.

• Refer to the FRENIC-Multi Instruction Manual

(INR-SI47-1094-E), Section 6.2.1 "Motor is running abnormally."

Loading...

Loading...