DRAWN BY:

CHECKED BY:

B.O.M. REVIEW: APPROVED BY:

ELECTRICAL REVIEW:

MECHANICAL REVIEW:

REVISIONDRAWING NUMBER

JOB NUMBER:

PROJECT NAME:

PROJECT MANAGER:

DESCRIPTION:

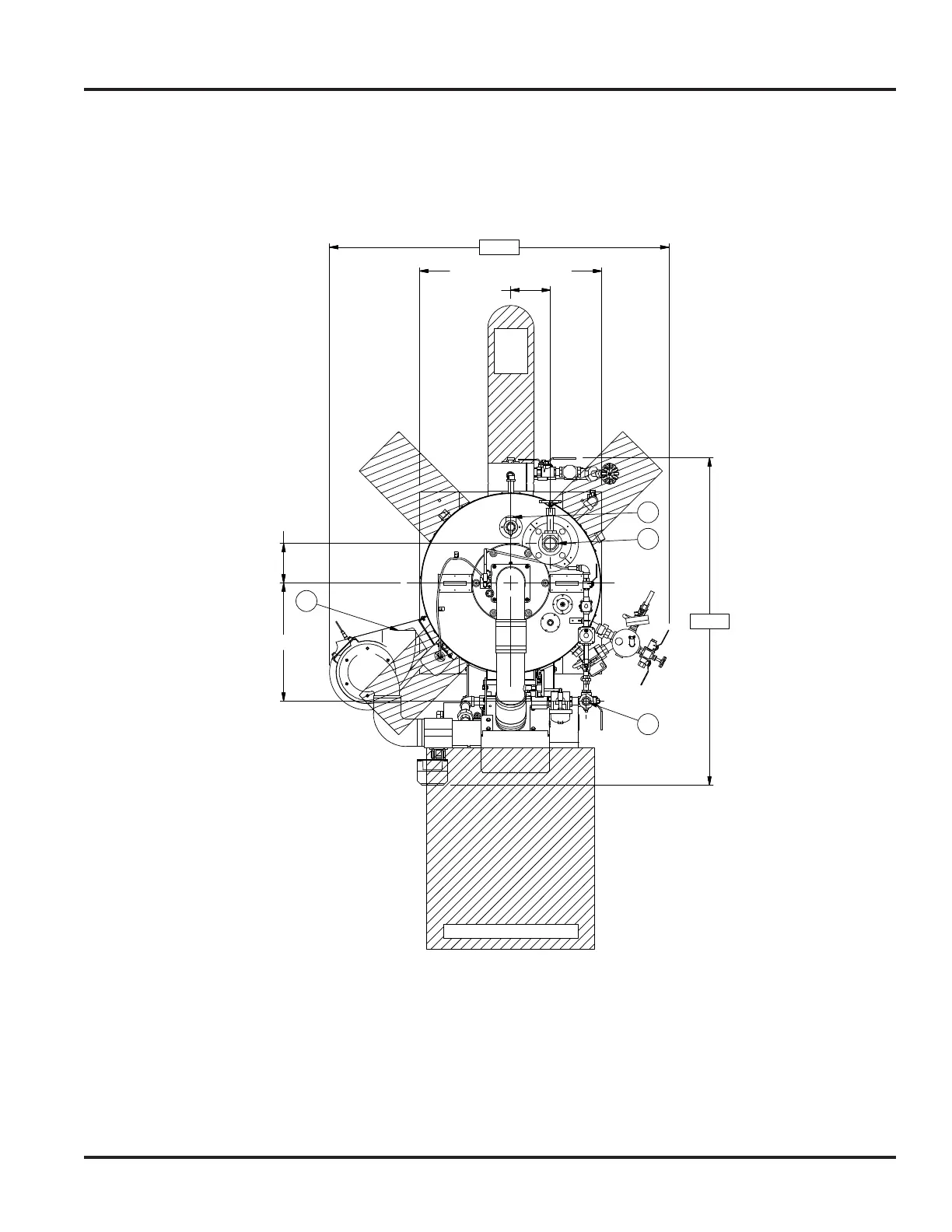

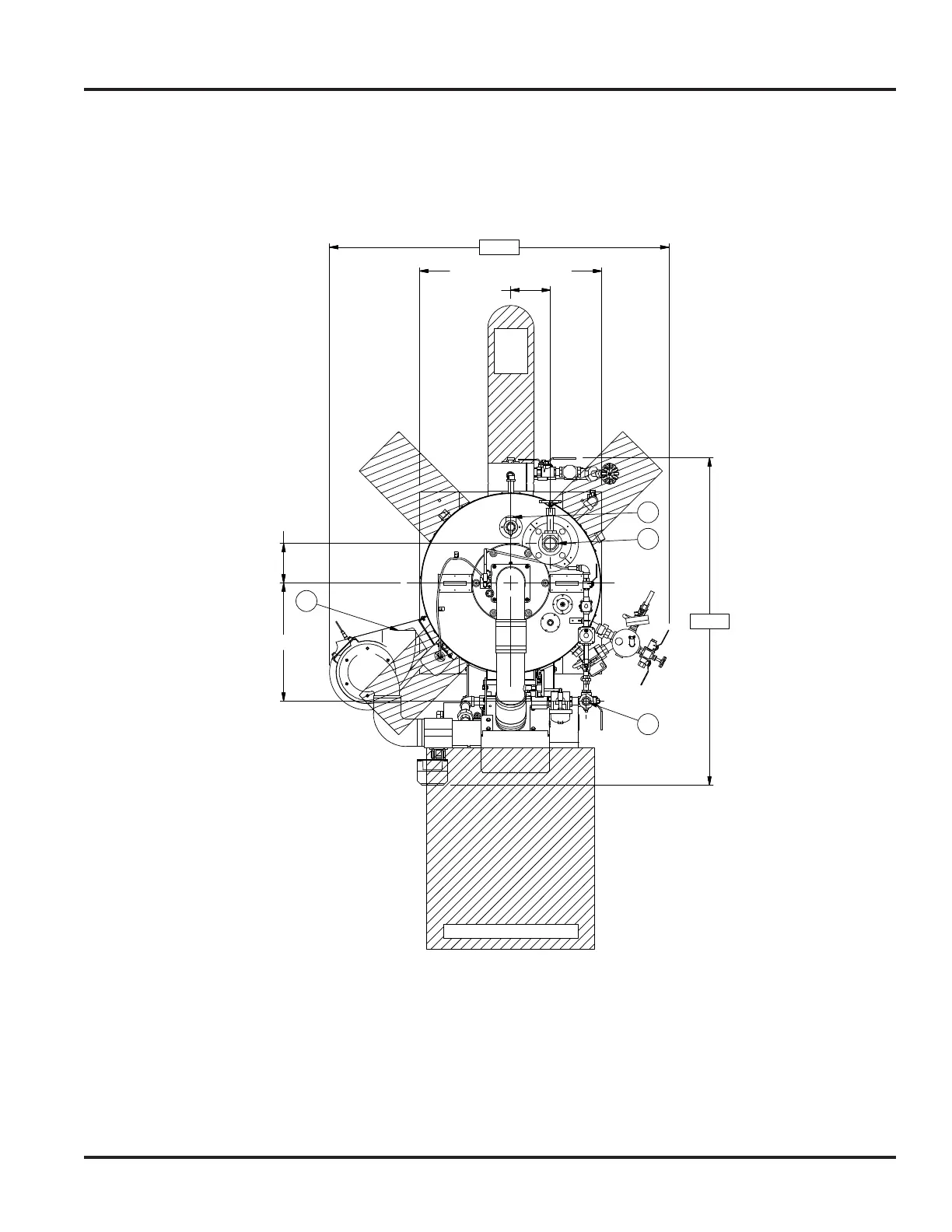

VSRT-20 GAS FIRED MODULATED STEAM BOILER

(150 PSI)

9-SR-020312 - PDS

-

T. KENNEDY

11/16/2017

N/A

N/A

W.W.

11/28/2017

N/A

E.B.W.

11/28/2017

This design and drawings are

proprietary and are the

exclusive property of The

Fulton Companies. The

corporation

does not permit

their use except with prior

written consent.

The items shown in this

drawing may be covered by

one or more patents of The

Fulton Companies.

SHEET 1 OF 1

THIRD ANGLE PROJECTION

TOLERANCES

FRACTION &

WHOLE VALUE

(1) PLACE DEC.

(2) PLACE DEC.

1/8

UNLESS OTHERWISE NOTED

DIMENSIONS ARE IN INCHES

0.03

(3) PLACE DEC.

SURFACE FINISH

250 MICRO-INCHES

0.005

0.5 DEGANGLE

0.015

Fulton Steam Solutions, Inc.

F

u

l

o

t

n

NOTES:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

STEAM OUTPUT LB/HR: FROM 0 PSIG AT 212

°F (0 KG/CM² AT

100°C)

ALL CLEARANCES ARE FACTORY RECOMMENDATIONS. CONSULT

LOCAL JURISDICTION FOR EXACT CODE COMPLIANCE.

FULTON RECOMMENDS MINIMUM CLEARANCE OF 36" IN FRONT

OF ELECTRICAL PANELS.

FULTON RECOMMENDS 36" CLEARANCE BETWEEN INSPECTION

OPENINGS OF ALL BOILERS, 18" CLEARANCE OF HANDHOLES,

AND 14" FROM EXHAUST STACK.

PLEASE REFER TO THE O&M MANUAL FOR ADDITIONAL

INFORMATION REGARDING CLEARA

NCES AND INSTALLATION

INSTRUCTIONS.

ALL DIMENSIONS INSIDE ( ) DENOTE REFERENCE DIMENSIONS.

ALL DIMENSIONS INSIDE

DENOTE OVERALL DIMENSIONS.

WE RESERVE THE RIGHT TO CHANGE SPECIFICATIONS

AND/OR DIMENSIONS. ALL INFORMATION IS SUBJECT

TO CHANGE BASED ON ADDITION OF ANY OPTIONAL

EQUIPMENT AND/OR ACCESSORIES. PLEASE CONSULT THE

FACTORY FOR PROJECT SPECIFIC ESTIMATES IF

ADDITIONAL OPTIONS OR ACCESSORI

ES ARE REQUIRED.

RECOMMENDED STACK RUN IS MINIMUM 24" STRAIGHT OFF

THE REAR OF THE BOILER, PRIOR TO MAKING A

DIRECTIONAL CHANGE.

LOCAL CODES CAN SUPERCEDE FULTON RECOMMENDED

CLEARANCE.

*SIZE AND/OR TYPE DEPENDS ON TRIM PRESSURE.

MAX ALLOWABLE WORKING PRESSURE:

BOILER OUTPUT:

MINIMUM INCOMING GAS PRESSURE:

150 PSI

670,000 BTU/HR

690 LBS/HR

65 SQ. FT.

112 GAL.

2,711 LBS.

3,645 LBS.

3,281 LBS.

EQUIPMENT SP

ECIFICATION CHART

APPROXIMATE FLOODED WEIGHT:

MINIMUM DRAFT REQUIREMENT:

BURNER TURNDOWN:

3,939 LBS.

4:1

-0.25" W.C.

APPROXIMATE SHIPPING WEIGHT:

APPROXIMATE OPERATING WEIGHT:

APPROXIMATE DRY WEIGHT:

WATER CAPACITY (OPERATING):

NET EFFECTIVE HEATING SURFACE:

STEAM OUTPUT/MIN. SRV CAPACITY:

800 CU FT/HR

BOILER INPUT:

3" W.C.

BOILER INPUT: (NATURAL GAS)

800,000 BTU/HR

CUSTOMER CONNECTIONS

ITEM DESCRIPTION SIZE TYPE

A FEED

WATER INLET 1" N.P.T.

B BLOWDOWN OUTLET

1 1/4"

N.P.T.

C STEAM OUTLET*

2" N.P.T.*

D EXHAUST STACK

8"

- - -

E

SAFETY RELIEF VALVE* 1"

N.P.T.

F

FUEL INLET

1" N.P.T.

G WATER COLUMN DRAIN 1" N.P.T.

H SIGHT GLASS DRAIN

1/4"

N.P.T.

J WATER SAMPLE PORT

1/4"

N.P.T.

K STEAM SAMPLE PORT

1/4"

N.P.T.

L

SURFACE BLOWDOWN (PLUGGED) 3/4"

N.P.T.

M

HIGH WATER PROTECTION (CAPPED)

3/4"

N.P.T.

N SINGLE SOURCE POWER

- - -

N.P.T.

P COMBUSTION AIR INLET

6"

- - -

R

AUXILIARY

WATER COLUMN (CAPPED)

1"

N.P.T.

ELECTRICAL REQUIREMENTS

VOLTAGE OPERATING FLA

120/1/60

10 AMPS

NOTE: OPERATING FULL LOAD AMPERAGE (FLA)

REFERS TO THE BOILER'S RATED CURRENT DRAW

AT HIGH FIRE.

Loading...

Loading...