Profession Laser Manufacturer more than 15 Years.

58

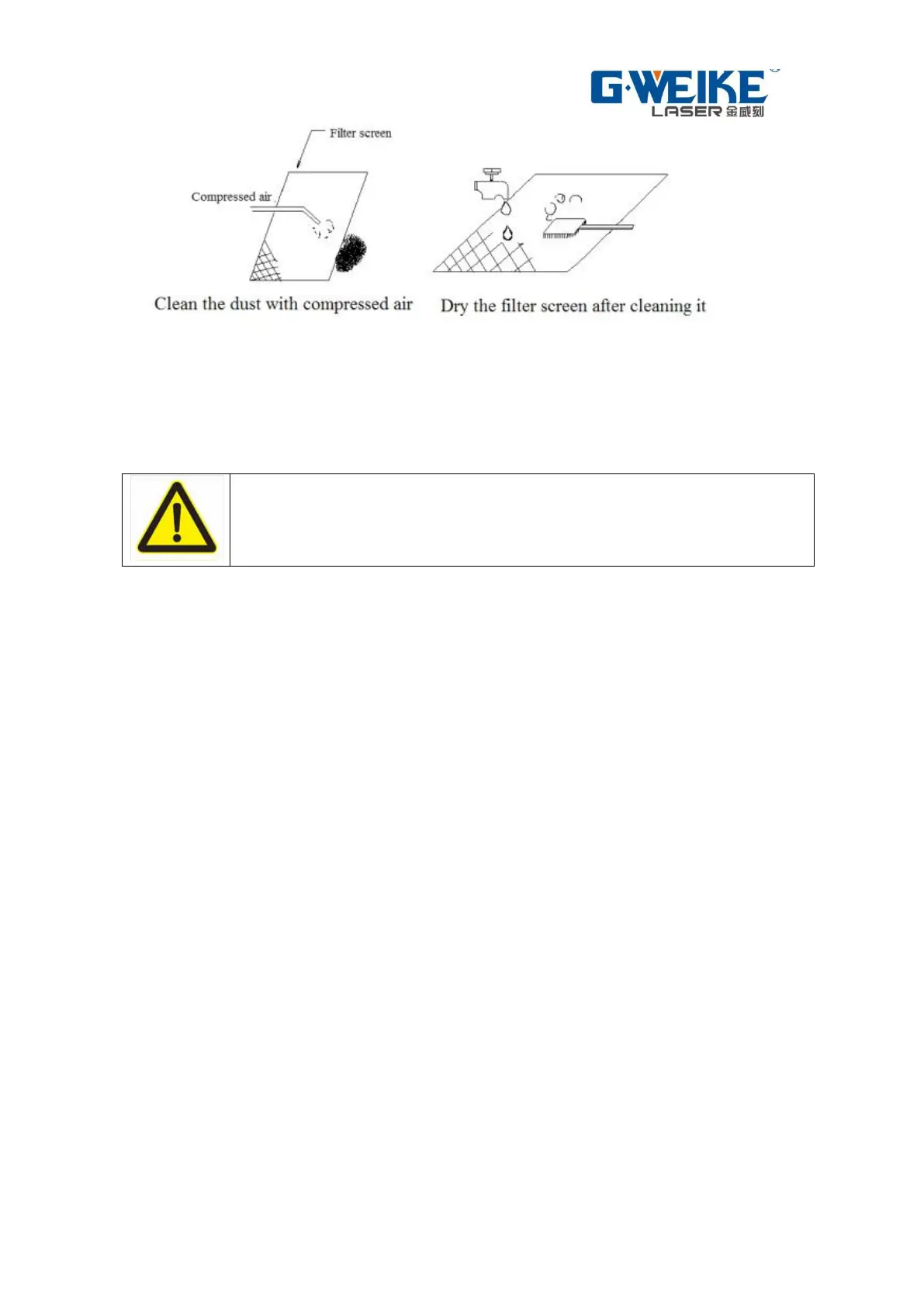

Picture 6-3

6.2.2 Laser Source and laser head Module maintenance

Fiber laser source can do basically free maintenance, the main daily

observation of cooling water and cooling air conditioning is normal; The voltage

is normal! If there is abnormal alarm immediately bond after-sales service!

Caution: Don’t dismantle or fix the laser source on

your own, Please contact with our company when the

laser source having problems.

6.3 Optical system inspection and cleaning

6.3.1 Something should pay attention

Optical lenses (protection lens and focus lens, etc.) on the surface, don't

touch by hand directly, causing mirror surface scratch so easily. If there is

grease or dust on the mirror, will seriously affect the use of the lens, we suggest

check the lens every week and clean them in time.Please check and clean the

lens according to the practical situation.

The optical lenses are strictly forbidden to use water and detergent to

clean. Lens surface coated a layer of special membrane, if use these to

clean the lens will damage the surface of the lens.

Do not use the lens placed in damp places, this will make the lens surface

aging.

The lens surface is stained with dust, dirt, or water vapor, easy absorption

laser lens coating damage; Light affects the quality of the laser beam, or

generating a laser beam.

Lens injury occurs, should be repaired in a timely manner to the suppliers,

and do not use the lens have been damaged as far as possible, otherwise

will accelerate damage could repair the lens.

In the installation or replacement mirror or focus lens, do not use too much

pressure, otherwise it will cause deformation of the lens, thus affect the

quality of the beam.

6.3.2 Dismantle ,installation or replacement the method of optical lenses

The dismantle process of laser head from the machine body are totally

reverse with the install process.Please refer the installation process (chapter 4.4)

Loading...

Loading...