What to do if the laser source of my G-WEIKE LF1390 Cutter has problems?

- KKevin BrownAug 13, 2025

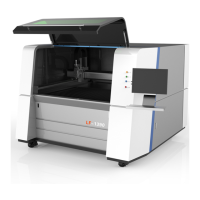

If the laser source of your G-WEIKE Cutter is experiencing issues, do not attempt to dismantle or fix it yourself. Please contact our company for assistance.