13-10-614 Page 10

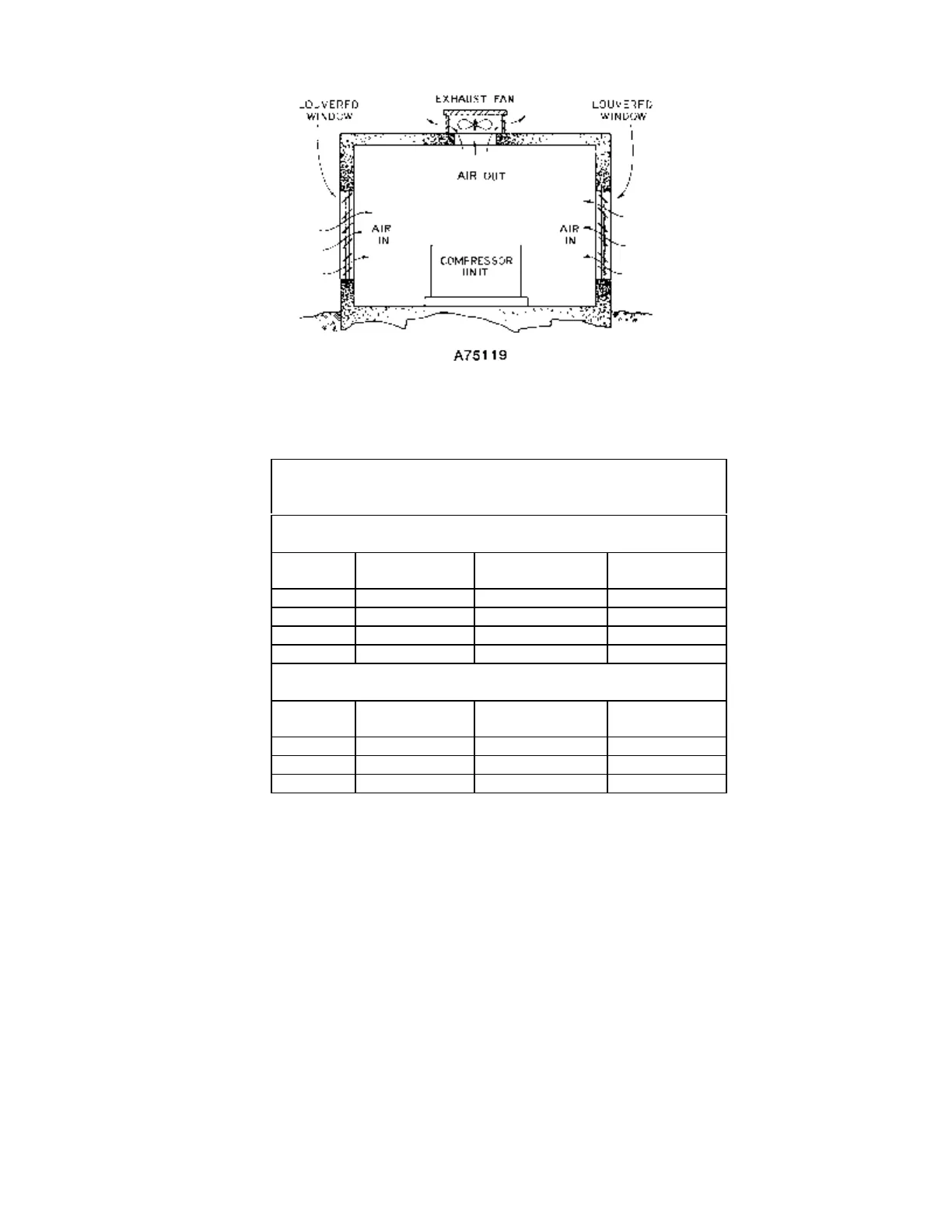

Figure 2-1 – TYPICAL COMPRESSOR ROOM

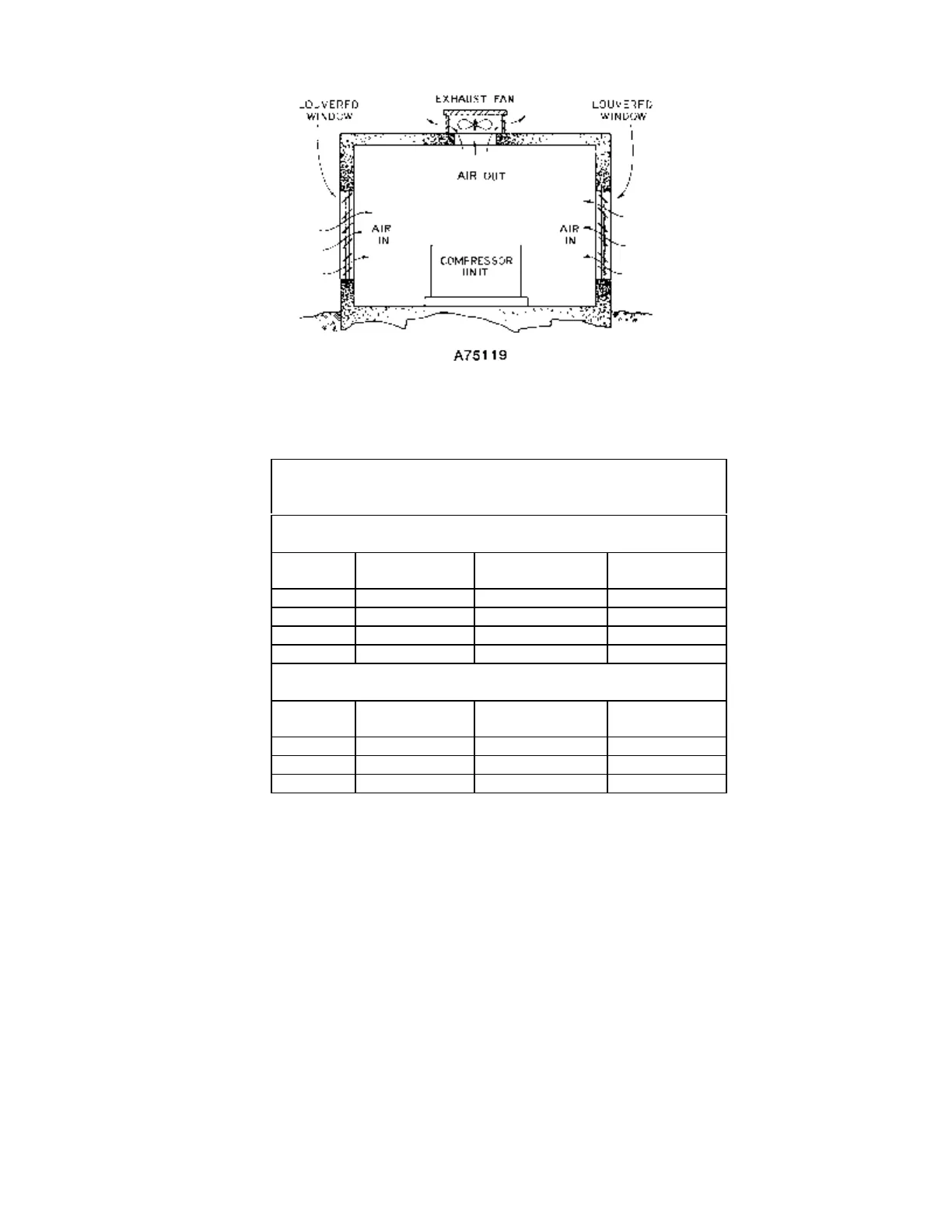

Minimum Air Flow * for Compression

and Cooling

DOMESTIC (CFM)

HP Air-Cooled

Package

Air-Cooled

Module

Water-Cooled

Package

200 28,500 20,500 8,000

250 35,900 26,000 9,900

300 37,900 26,000 11,900

INTERNATIONAL (M

3

/MIN)

KW Air-Cooled

Package

Air-Cooled

Module

Water-Cooled

Package

150 806 580 226

186 1,016 736 280

224 1,072 736 337

* 80° F (27° C) Inlet Air

Figure 2-2 – AIR FLOW CHART

Air-Cooled Units - A combination oil/aftercooler is supplied as standard equipment on all air-cooled

units. The air-cooled unit with the standard enclosure requires sufficient flow, Figure 2-2, for the

compressor oil/aftercooling system and for electric motor cooling. Air is drawn into the unit at the motor

side of the enclosure and is exhausted at the oil cooler side. Do not block the air flow to and from the

unit. Allow three and one-half (3-1/2) feet (1.1 m) to the nearest obstruction on the starter end and control

box end of the unit. Allow three (3) feet (.9 m) to the nearest obstruction above and on other sides of unit.

For continuous efficiency, oil cooler cores must be periodically cleaned with either vacuum or compressed

air. If wet cleaning is required, shield motor and spray on a mild soap solution and flush with clean water.

Water-Cooled Units - The water-cooled unit with the standard enclosure requires sufficient air flow,

Figure 2-2, page 10, for electric motor cooling. Air is drawn into the unit at the top of the enclosure and is

exhausted at the motor side. Do not block air flow to and from unit. Allow three and one-half (3-1/2) feet

Loading...

Loading...