13-10-614 Page 28

COMPRESSOR CAPACITY CONTROL

The capacity of the compressor is controlled by the action of the Turn Valve and the Compressor Inlet

Valve.

The turn valve controls compressor delivery to match demands of 40% to 100% of the compressor’s

maximum capacity. The inlet valve throttles to control compressor delivery to match demands of 0% to

40% of the compressors maximum capacity.

Example with normal setting of 100 PSIG:

Compressor Delivery Inlet Valve Position Turn Valve Position

Discharge Manifold

Pressure (psi)

Full Capacity Open Closed 100

70% Capacity Open 50% Open 100

40% Capacity Open Full Open 100

30% Capacity Closing Full Open 103

20% Capacity Closing Full Open 103

0% Capacity Closed Full Open 103

Turn Valve - The turn valve is a helical valve which, when rotated, opens and closes a series of ports

cast into the compressor cylinder. When these ports are open, they direct some of the air which would

otherwise be compressed back to the inlet, reducing both capacity and power consumption.

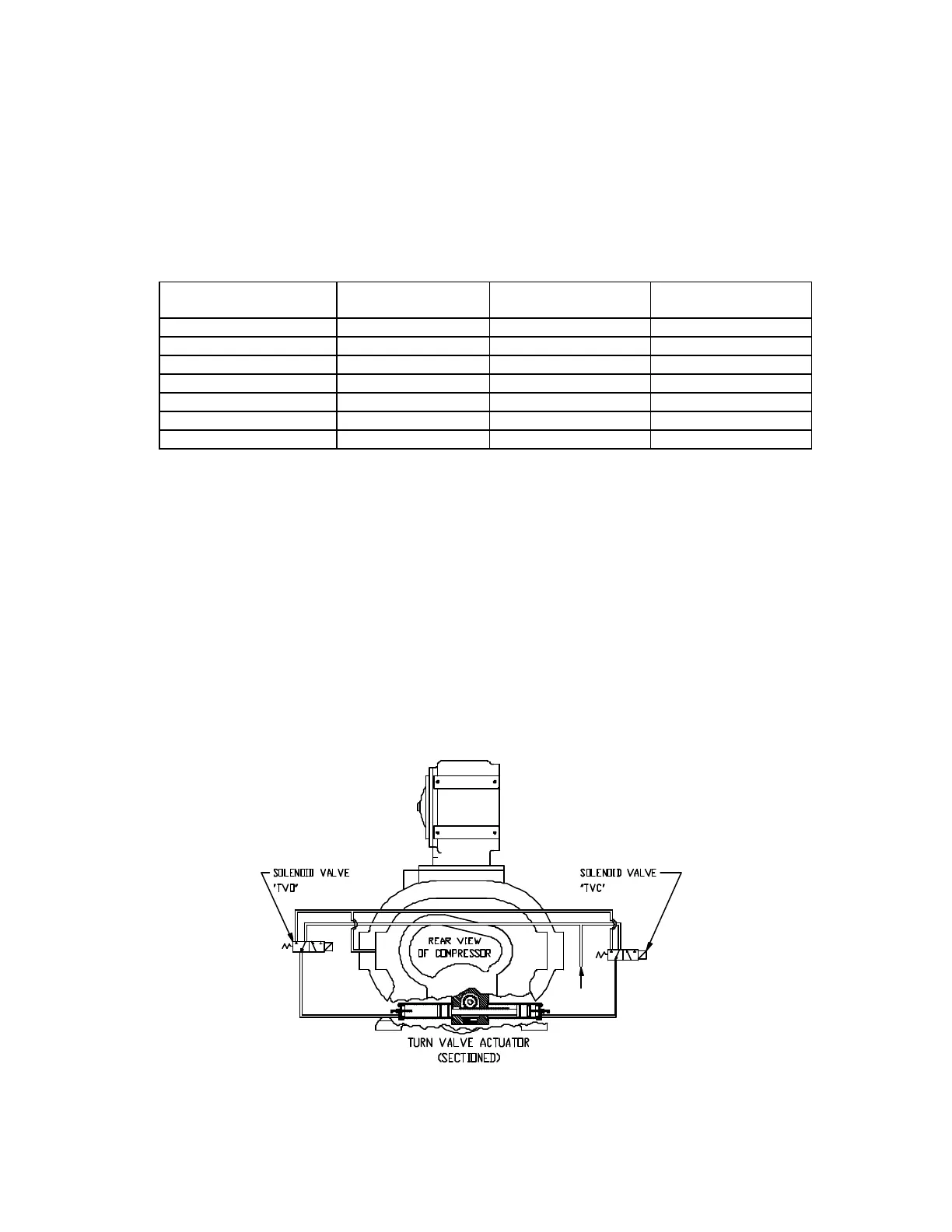

Turn Valve Actuator (Figure 4-6) - The turn valve actuator is a rotary rack and pinion device which

positions the turn valve according to system demand. Filtered oil from the reservoir is directed to the

outboard ends of the two actuating cylinders to move the rack and rotate the valve. Located on the end

of the cylinders are adjusting screws which limit the travel of the actuator. When looking at the rear of the

compressor, the adjusting screw on the right on the compressor adjusts the fully closed (full load) position

of the valve. The full load position of the actuator may be checked by removing the adjusting screw at the

unloaded end of the actuator (left side of the compressor) and using a rod to push the pistons to the full

load position. The rod must be clean and free of burrs and scale. Take care not to scrape the cylinder

walls when moving the pistons.

Figure 4-6 – TURN VALVE ACTUATOR (SECTIONED)

(Ref. Drawing)

Loading...

Loading...