13-20-604 Page 12

N

N

N

O

O

O

T

T

T

I

I

I

C

C

C

E

E

E

For aluminum oil coolers, do not use any cleaning solution that is not

compatible with aluminum. Use of improper solution may result in damage to

the cooler.

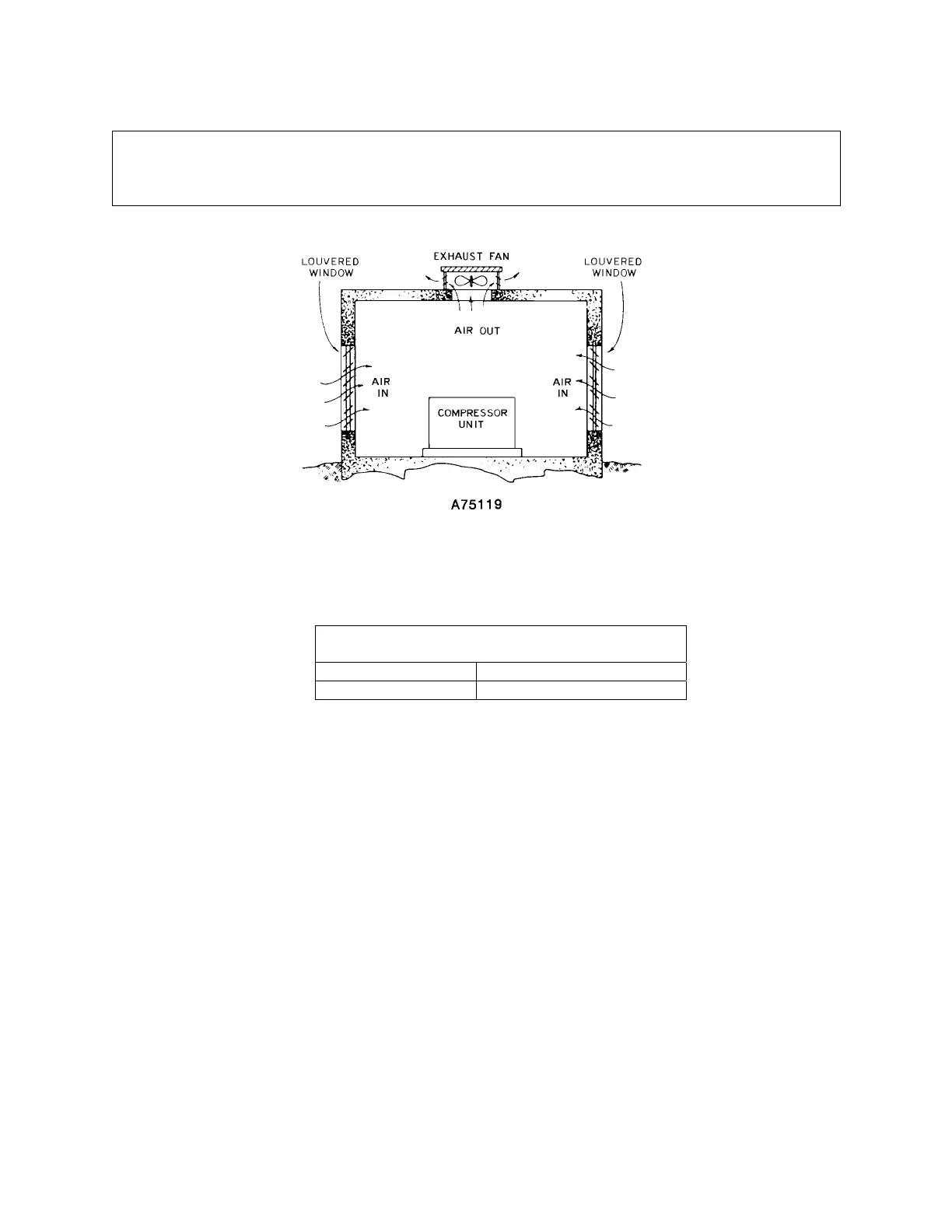

Figure 2-1 – TYPICAL COMPRESSOR ROOM

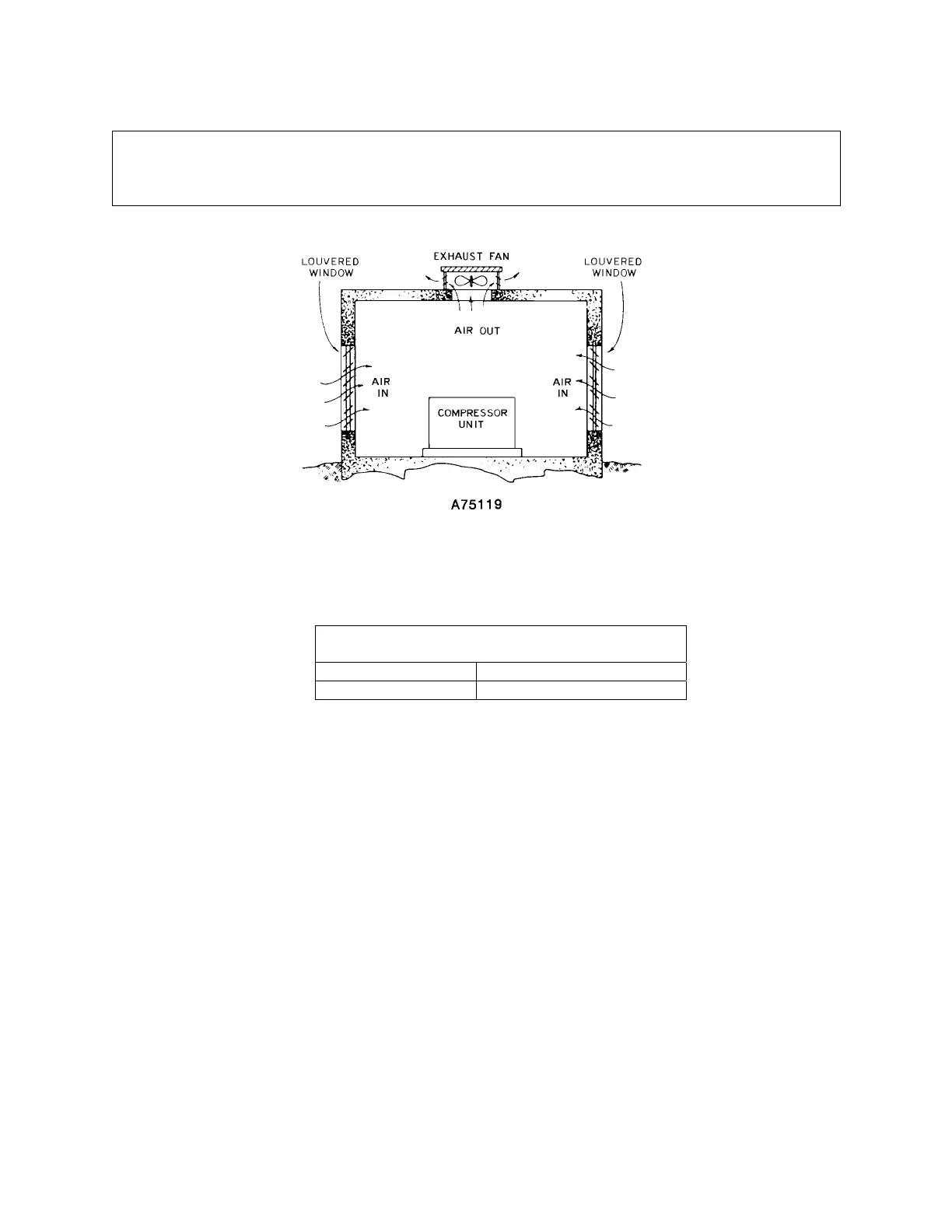

Minimum Air Flow* For Compressor

And Cooling (cubic Feet/Minute)

Air Cooled

All Models 4800 cfm

* 80° F Inlet Air

Figure 2-2 – AIR FLOW CHART

FOUNDATION - The rotary screw compressor requires no special foundation, but should be mounted on

a smooth, solid surface. Whenever possible install the unit near level. Temporary installation may be

made at a maximum 5° angle lengthwise or 5° sidewise. Mounting bolts are not normally required.

However, installation conditions such as piping rigidity, angle of tilt, or danger of shifting from outside

vibration or moving vehicles may require the use of mounting bolts and shims to provide uniform support

for the base. Belt alignment and tension should be checked after installation. (For information on belt

alignment and tension, see SECTION 7, page 49.

OIL RESERVOIR DRAIN - The oil drain is piped from the bottom of the reservoir to the side of the frame.

This drain is approximately 20 inches above the floor level.

Loading...

Loading...