13-20-604 Page 42

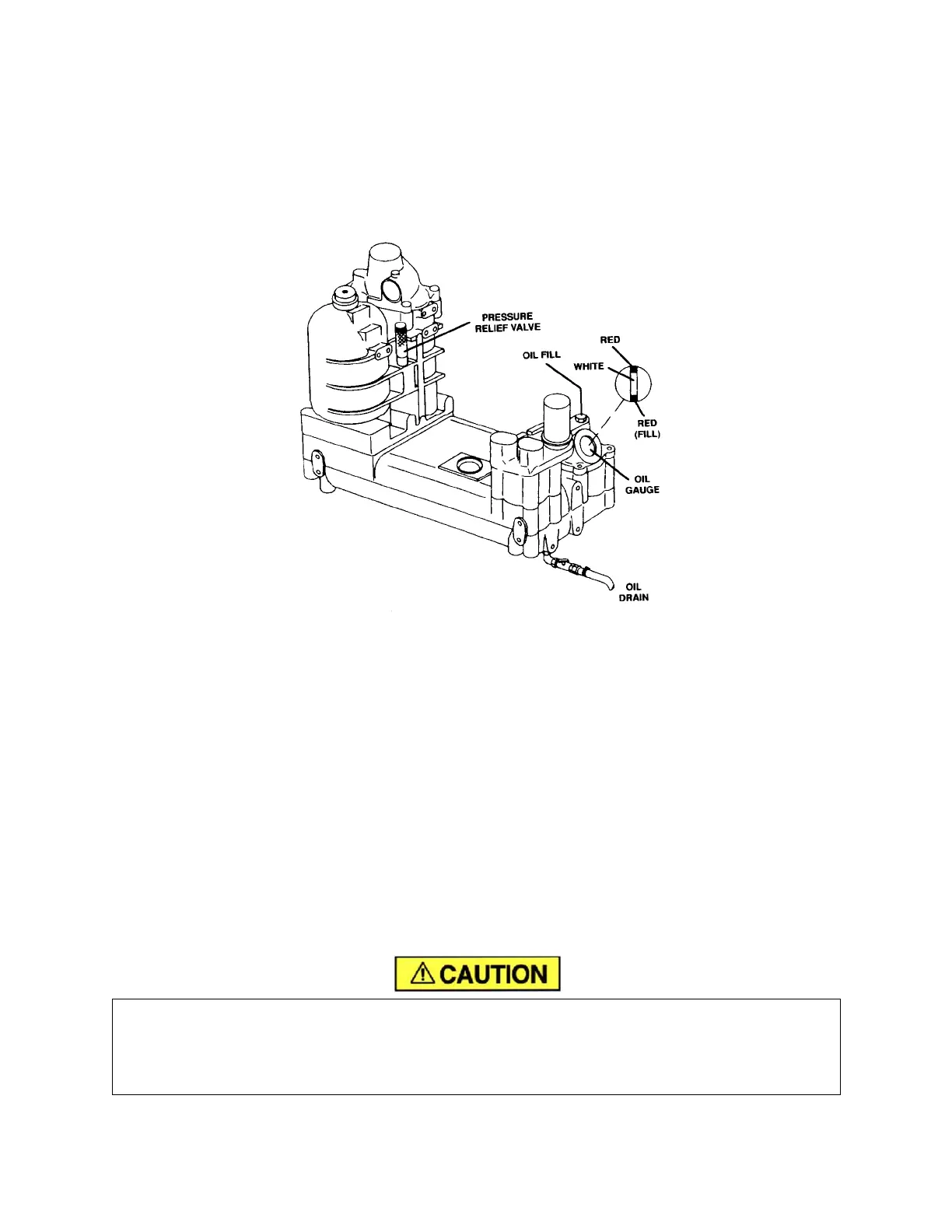

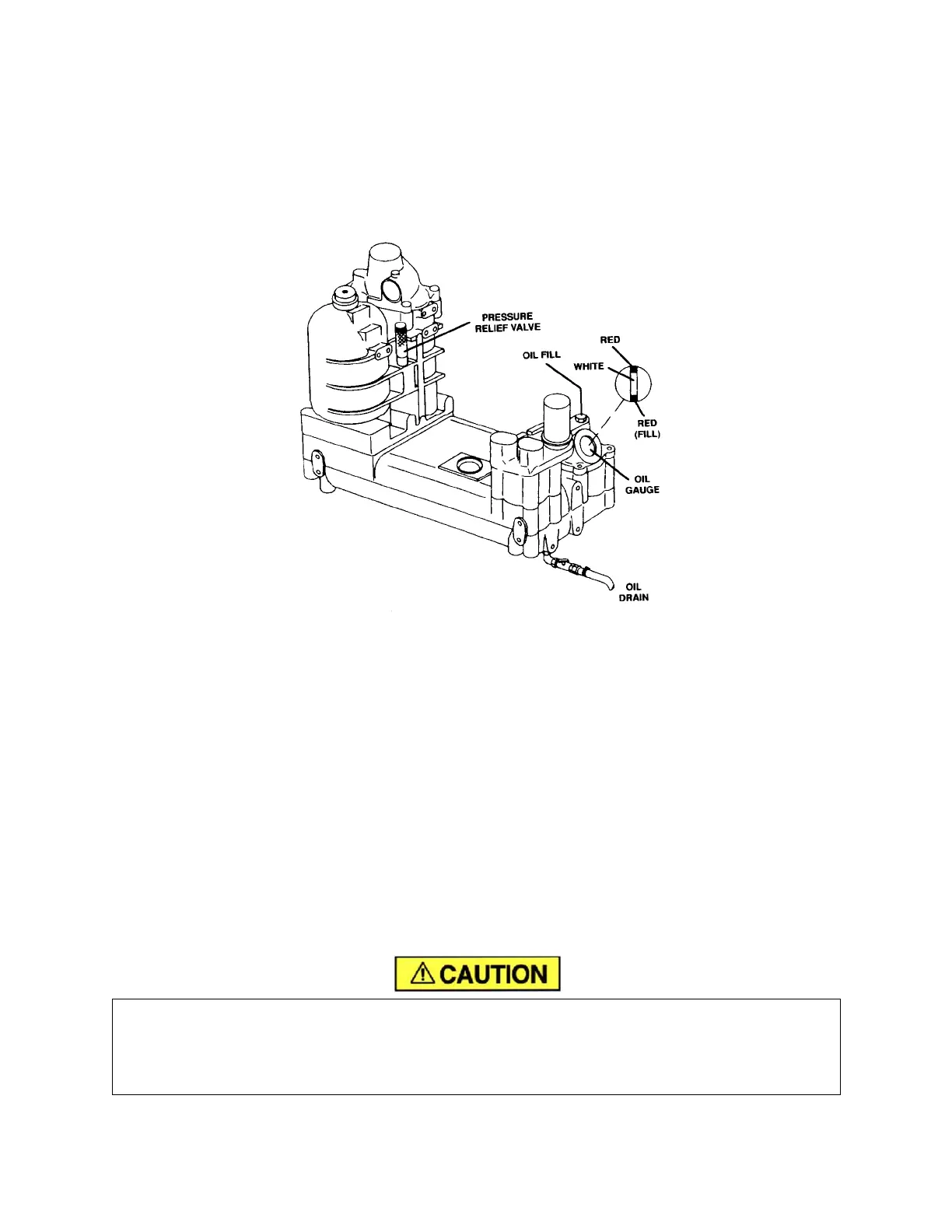

OIL LEVEL GAUGE (Figure 5-4, page 42) - The oil level gauge indicates the amount of oil in the air/oil

reservoir. Read oil level only when the unit is shut down and the air/oil mixture has separated. Add oil

only when the oil level is in the bottom red range, below the white range on the gauge (you must use a

flashlight). Drain oil only when the oil level is in the upper red range above the white range on the gauge

(you must use a flashlight).

Figure 5-4 – OIL LEVEL GAUGE, OIL FILL AND OIL DRAIN

MOISTURE IN THE OIL SYSTEM - In normal humidity and with normal operating temperatures and

pressures, the thermal mixing valve controls the oil temperature and prevents moisture contamination of

the oil. Unusual cooling of the oil reservoir, short loaded cycle in high humidity or malfunctions of the

thermal valve may result in moisture in the oil system which is detrimental to compressor lubrication and

could cause oil carryover. If moisture is observed in the oil reservoir, drain the moisture and correct the

condition causing the accumulation.

See “Compressor Oil System Check”, page 46 and “Thermal Control (Thermostatic Mixing) Valve”, page

44.

COMPRESSOR OIL FILTER (Figure 1-2, page 10 and Figure 5-5, page 43) - This replaceable element

filter is a vital part in maintaining a trouble-free compressor, since it removes dirt and abrasives from the

circulated oil.

Improper oil filter maintenance will cause damage to equipment. Replace filter

element every 1000 hours of operation. More frequent replacement could be

required depending on operating conditions. A filter element left in service too

long may damage equipment.

Loading...

Loading...