13-20-604 Page 24

SECTION 4

CONTROLS & INSTRUMENTATION

GENERAL DESCRIPTION

The Gardner Denver rotary screw compressor is prewired with all controls, motor, and starter for the

voltage and horsepower at the time of ordering. It is necessary only to connect the compressor unit to the

correct power supply and to the shop air line. A standard compressor unit consists of the compressor, oil

reservoir, oil cooling system and filter, motor type as specified, NEMA 12 starter / control box, and control

components as described below.

AIRSMART

®

CONTROL OPERATION

Operation of the "AirSmart

®

" Control is dependent on selection of an operating mode from the controller

keypad. Prior to starting, the STOP/RESET key must be pressed to place the controller into its READY

state (as indicated on the display). Compressor operation may then be started by pressing the RUN key.

While in any operating mode, the display will indicate the mode, and the operating light will be on.

Press the STOP/RESET key at any time to stop the compressor under normal conditions.

AUTOMATIC is the most common selected mode of operation, as it automatically will operate the

compressor unit in the most efficient manner for the demand of the air system. Refer to the controller

manual for descriptions of other modes.

Automatic restarting or electrical shock can cause injury or death. Disconnect,

lockout and tagout the unit from the power supply and any other circuits before

servicing unit.

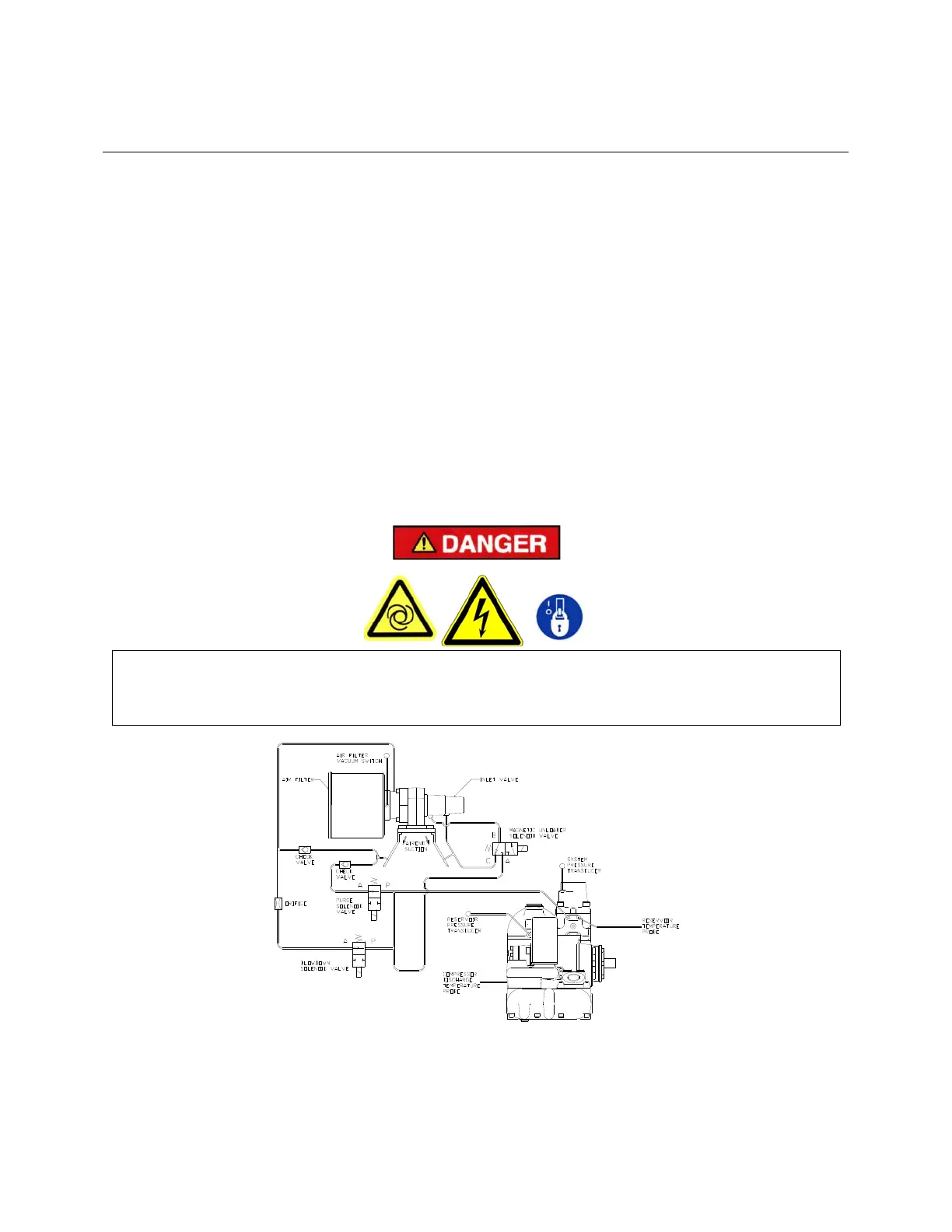

Figure 4-1 – CONTROL SCHEMATIC

301EFD797-D

(Ref. Drawing)

Loading...

Loading...