Chapter 1. Installation

4 DigitalFlow™ XGM868i Startup Guide

1.4 Installing a Flowcell

A flowcell is the section of pipe where the transducers are mounted. It can be created either by mounting the

transducers on the existing pipeline or by mounting them on a spoolpiece. A spoolpiece is a separately manufactured

pipe section, matched to the existing pipe, which contains ports for mounting the transducers. This approach allows the

transducers to be aligned and calibrated before inserting the spoolpiece into the pipeline.

Figure 1 on page 2 shows a typical Model XGM868i spoolpiece, with a mounting bracket to hold the electronics

enclosure. For detailed instructions on installing the transducers and/or spoolpiece, refer to the supplied drawings and

the enclosed GE Gas Transducer Installation Guide (916-049).

1.5 Installing Temperature and Pressure Transmitters

Optional temperature and pressure transmitters may be installed near the ultrasonic transducer ports as part of the

flowcell. Be sure to observe the siting requirements given earlier in this chapter. These transmitters should send a

0/4-20 mA signal to the Model XGM868i. In turn, the Model XGM868i must be fitted with a suitable option card to

process the signals and to provide the required 24 VDC power to the transmitters. Any desired transmitters or sensors

may be used, but they must have an accuracy equal to 0.5% of the reading or better.

Note: Resistive Thermal Devices (RTDs) are a good choice for measuring the temperature.

Typically, a 1/2” or 3/4” NPT female threaded port is used to mount the transmitters on the flowcell. If the pipeline is

insulated, the coupling may need to be extended to provide convenient access. Of course, other types of mounting

ports, including flanged ports, may be used for the transmitters.

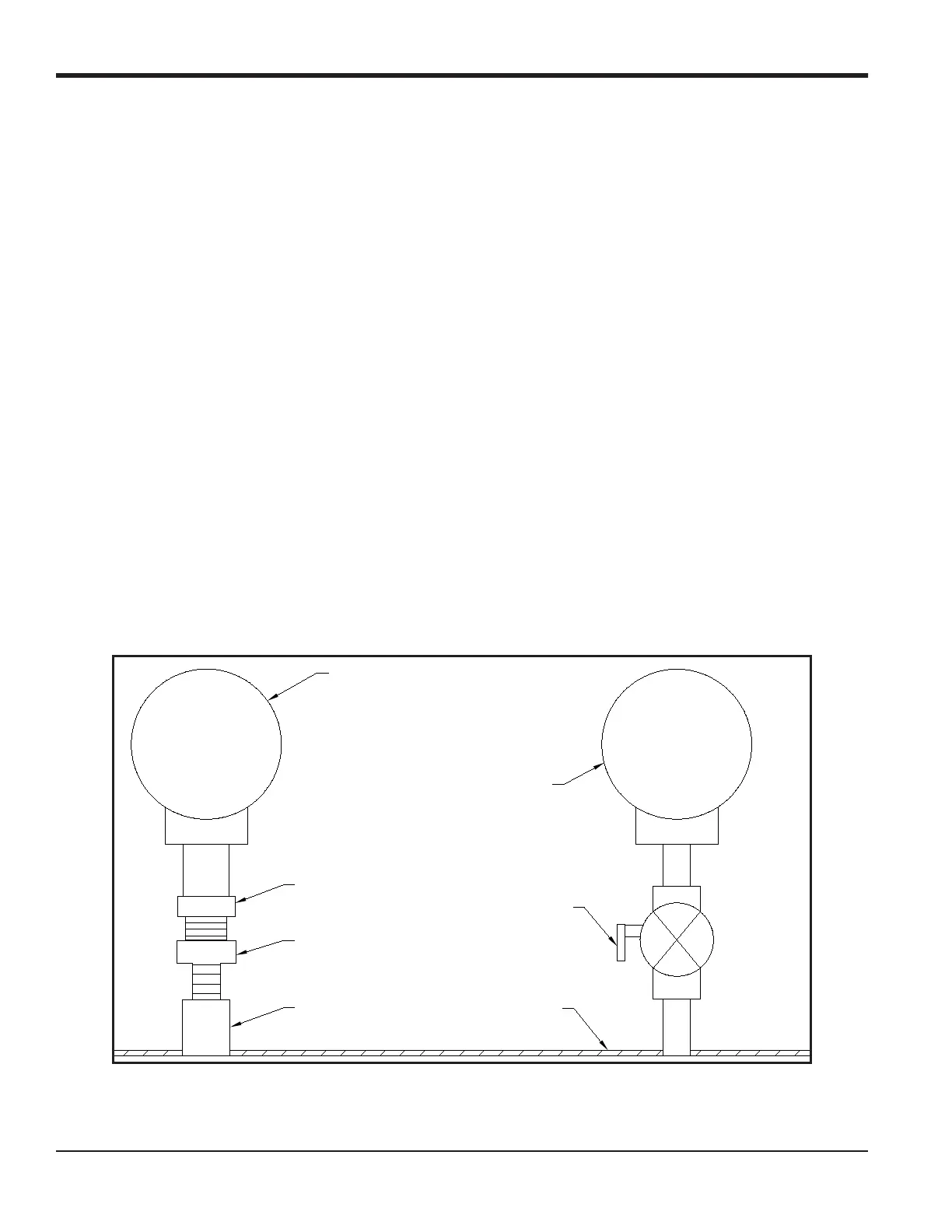

Figure 2 shows a typical mounting arrangement for the pressure and temperature transmitters. The temperature sensor

should protrude 1/4 to 1/2 way into the pipe.

Figure 2: Typical Temperature/Pressure Transmitter Mounting

Temperature Transmitter

RTD

Thermowell

Coupling

Pressure Transmitter

Isolation Valve

Flowcell Wall

Loading...

Loading...