Hydran* M2-X Installation Guide

MA-028 Rev. 2.1, 11-Jun-20

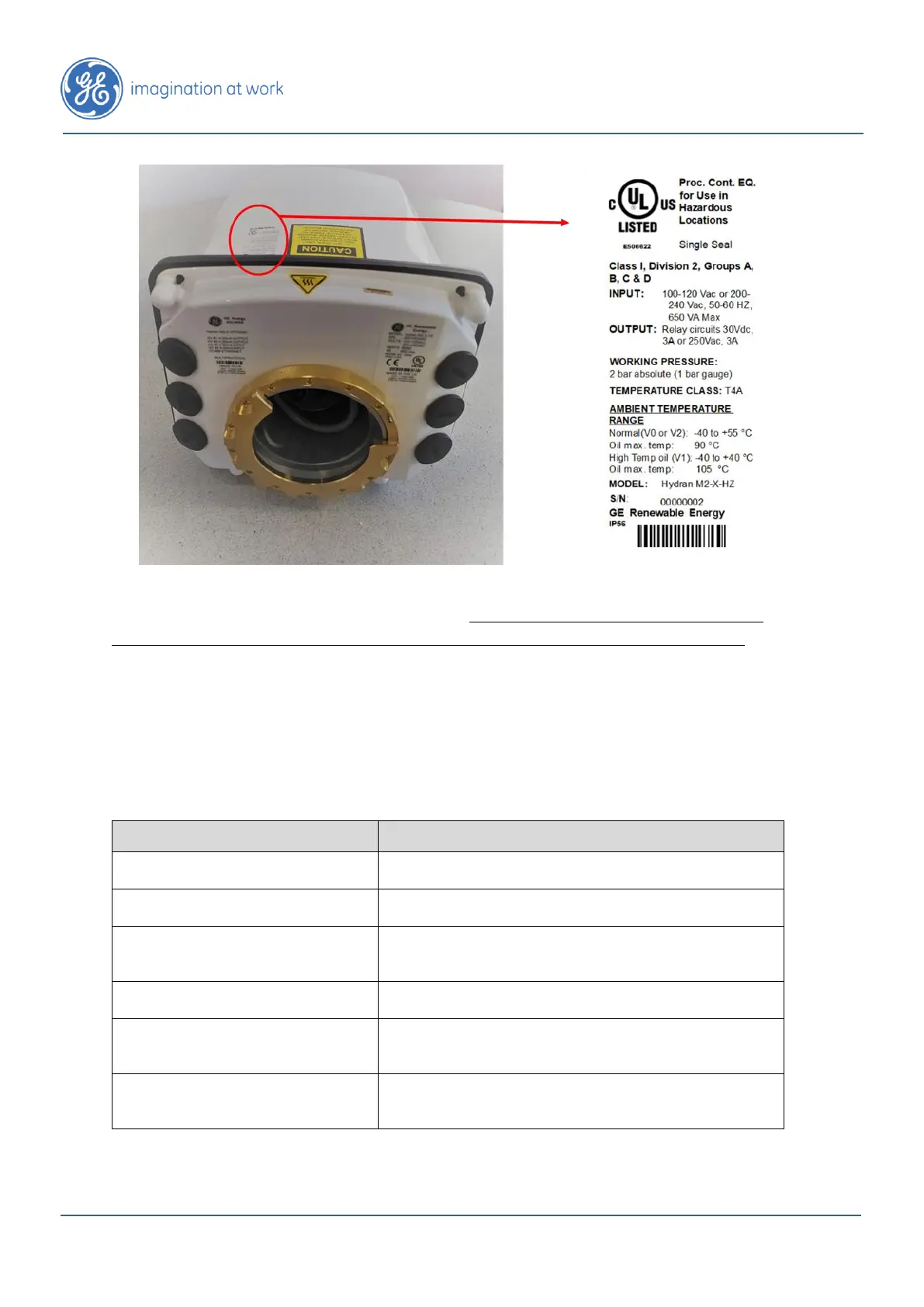

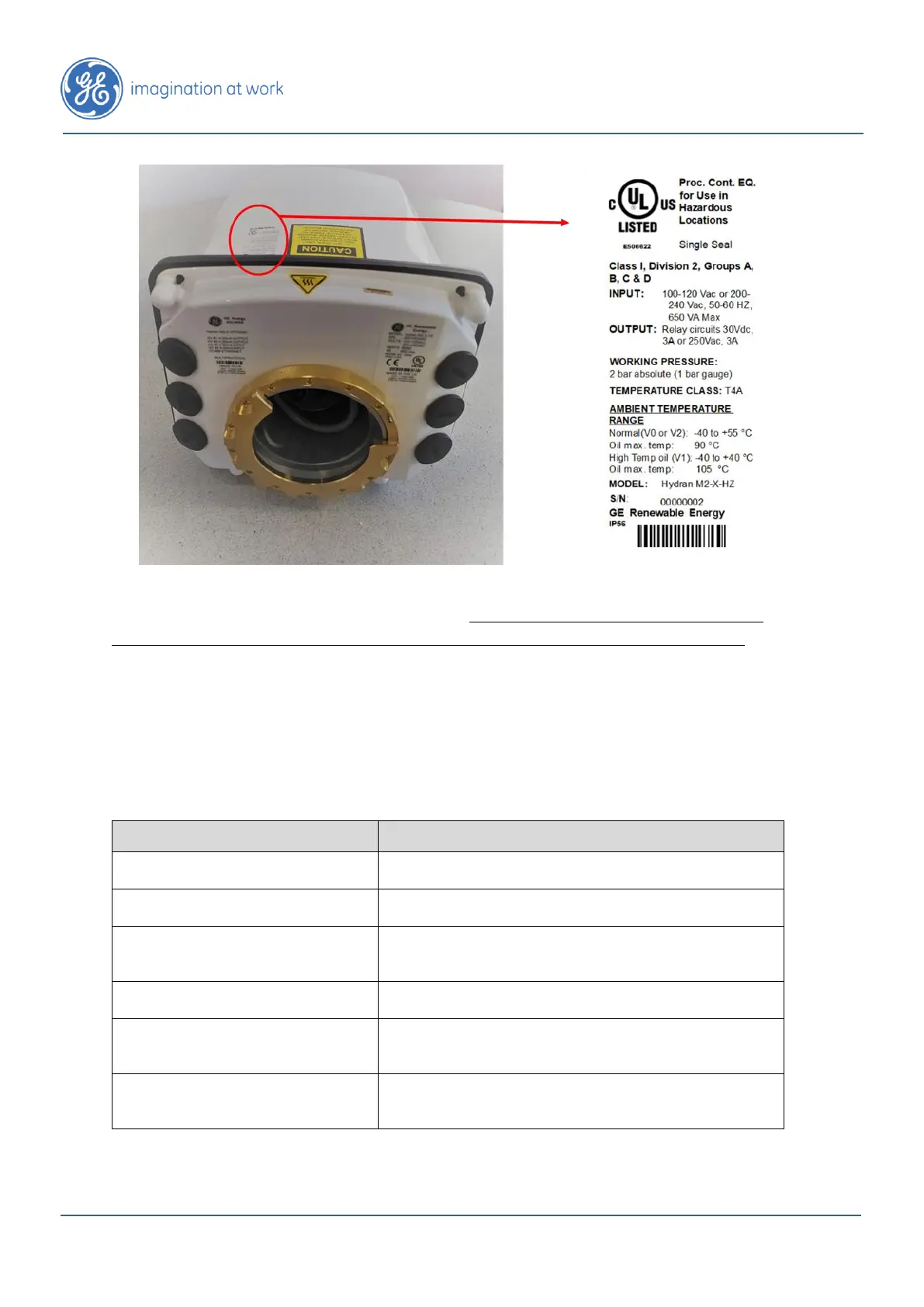

Figure 2: Hazardous location label

Note: In the case of a HazLoc certified product, please ignore additional appendices in

this document as they relate to a standard Hydran M2-X regarding servicing of parts, and

therefore are not applicable for a HazLoc certified product.

For any servicing needs, the unit must be removed from the transformer and returned

to a GE service centre.

Table 1 lists other HazLoc relevant materials for the Hydran M2-X / Hydran M2-X H2

that are in contact with oil under normal-use operations.

Table 1: List of product materials in oil contact

This is the constituent material of the sensor body.

Constituent material in V023, V029 & V030 O-rings

Glass to metal seal formed between sensor brass and

Humidity-in-oil sensor

DOW CORNING ® high vacuum grease

Greased O-rings create appropriate seals

Teflon Chemfilm® DF100 PTFE

This forms the outer layer of the oil-gas membrane in the

standard composite-gas sensor

This forms the outer layer of the oil-gas membrane in

standard Hydrogen only sensor

Loading...

Loading...