110

MAINTENANCE

¡the belt is worn and touches the bottom

of the V groove in the pulley.

¡the belt stretches and cannot be

adjusted.

Adjustment

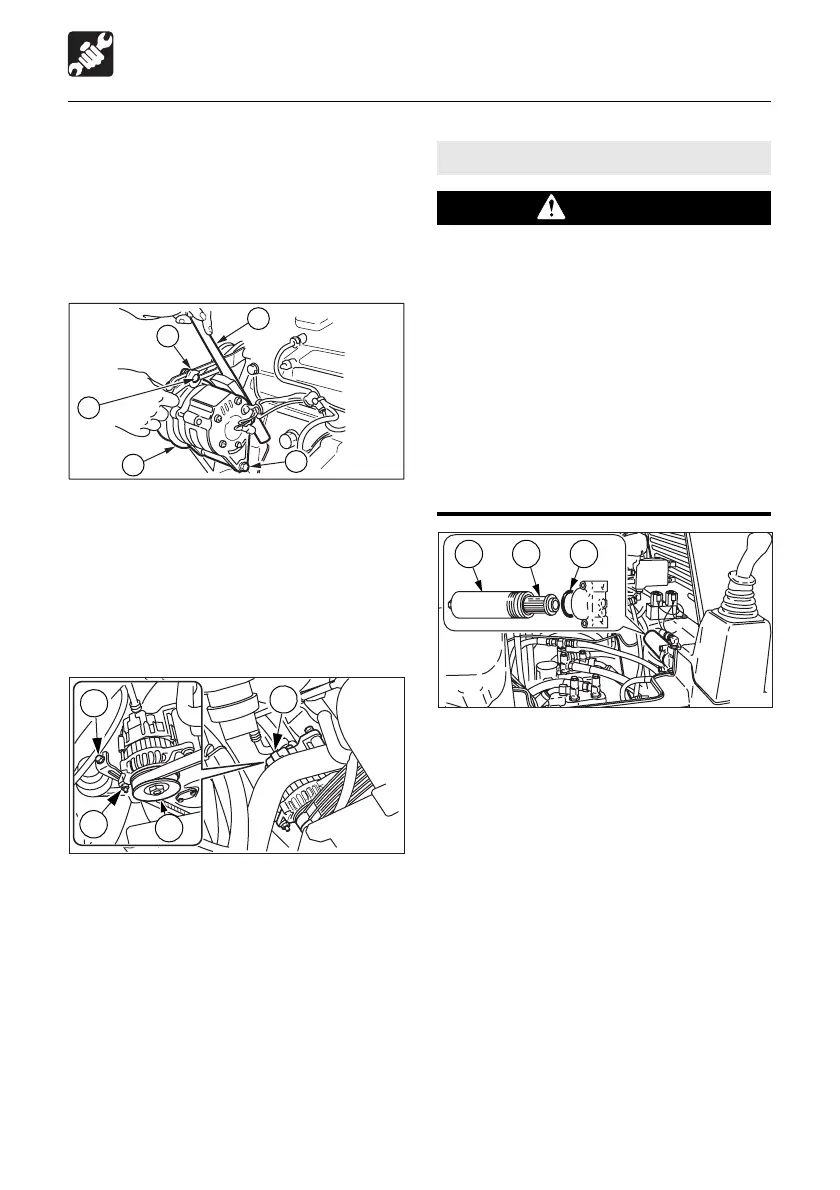

< CTL60 / CTL80 >

1. Loosen the adjustment bolt (5) and locking

nut (6).

2. Using a lever (7), move the alternator (8)

and adjust the slack.

3. Tighten the adjustment bolt (5) and locking

nut (6).

< CTL70 >

1. Loosen the locking nut (6).

2. Turn the adjustment bolt (5) and adjust the

fan belt (4).

¡Tighten: Clockwise

¡Loosen: Counterclockwise

3. Tighten the locking nut (6).

After First 50 Hours (New Machines Only)

Replacing the Line Filter

WARNING

¡¡

¡¡

¡Stop the engine and allow the machine

to cool down before performing

maintenance.

¡¡

¡¡

¡Oil may spurt out if caps or filters are

removed or pipes disconnected before

releasing the pressure in the hydraulic

system.

• When removing plugs or screws or

disconnecting hoses, stand to the

side and loosen slowly to gradually

release the internal pressure before

removing.

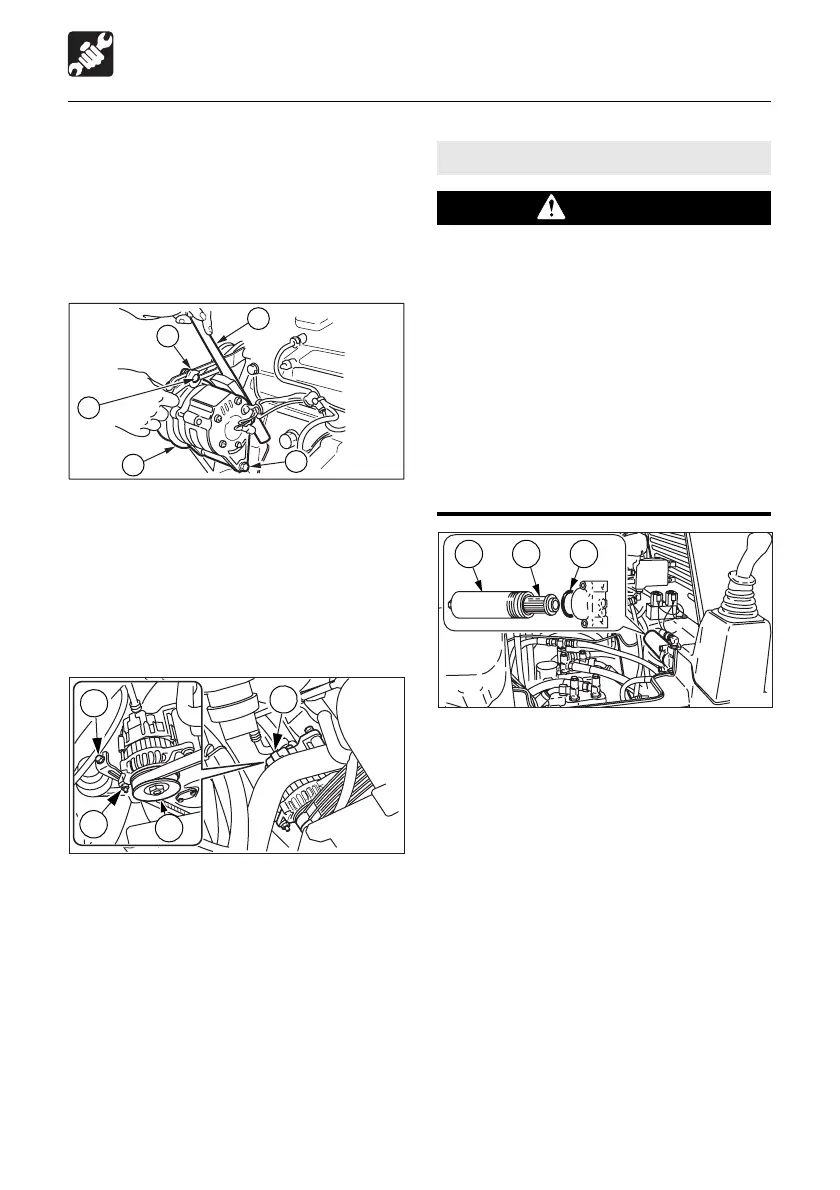

1. Tilt up the ROPS.

Refer to page 129 “Tilting Up the ROPS”.

2. Turn the case (1) counterclockwise and

remove it.

3. Remove the element (2) and O-ring (3).

4. Clean the inside of the case (1).

5. Install the new element in the case (1).

6. Set the new O-ring, then tighten the case

(1).

E4G018

5

7

B

8

6

T7G013

1

32

T9G008

6

5

8

3

Loading...

Loading...