上海鲍麦克斯电子科技有限公司 AS系列数控交流伺服系统说明书

8

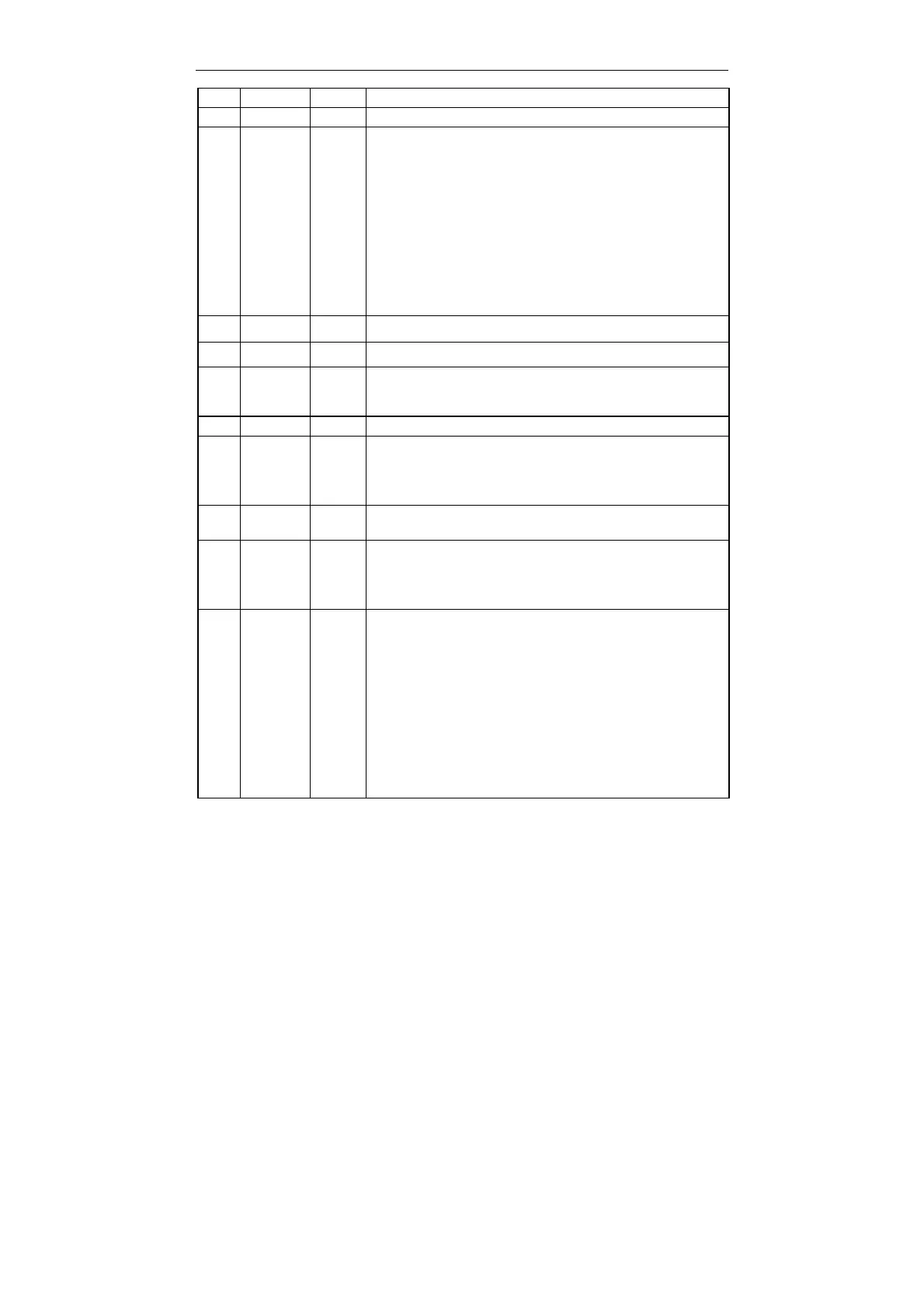

153 1~100 1

The proportion coefficient of the pieces counter

154 1~9999 1

Maximum pieces of the counter

155 0~4 0

Count mode selection (For Sewing Piece)

0: The counter is invalid

1: Count up by pieces. When count over, counter will be auto- reset.

2: Count down by pieces. When count over, counter will be auto-

reset.

3: Count up by pieces. When count over, motor stops and the

counter must be reset by the external switch or the P key on the

panel.

4: Count down by pieces. When count over, motor stops and the

counter must be reset by the external switch or the P key on the

panel.

156 0~9999 0

The output chopping duty cycle of No. 1/2/3/4 solenoid in each bit.

157 0~9999 0

The output chopping duty cycle of No. 5/6/7/8 solenoid in each bit.

158 0~1 0

Counter adjustable:

0:adjustable, 1:not adjustabled

160 0

Running time reset

161 0/1/2

Direction of parameter transfer:

0: no action

1: from operation panel to controller

2: from controller to operation panel.

165 -

Restore the default factory setting, and cover the user defined para

setting,.

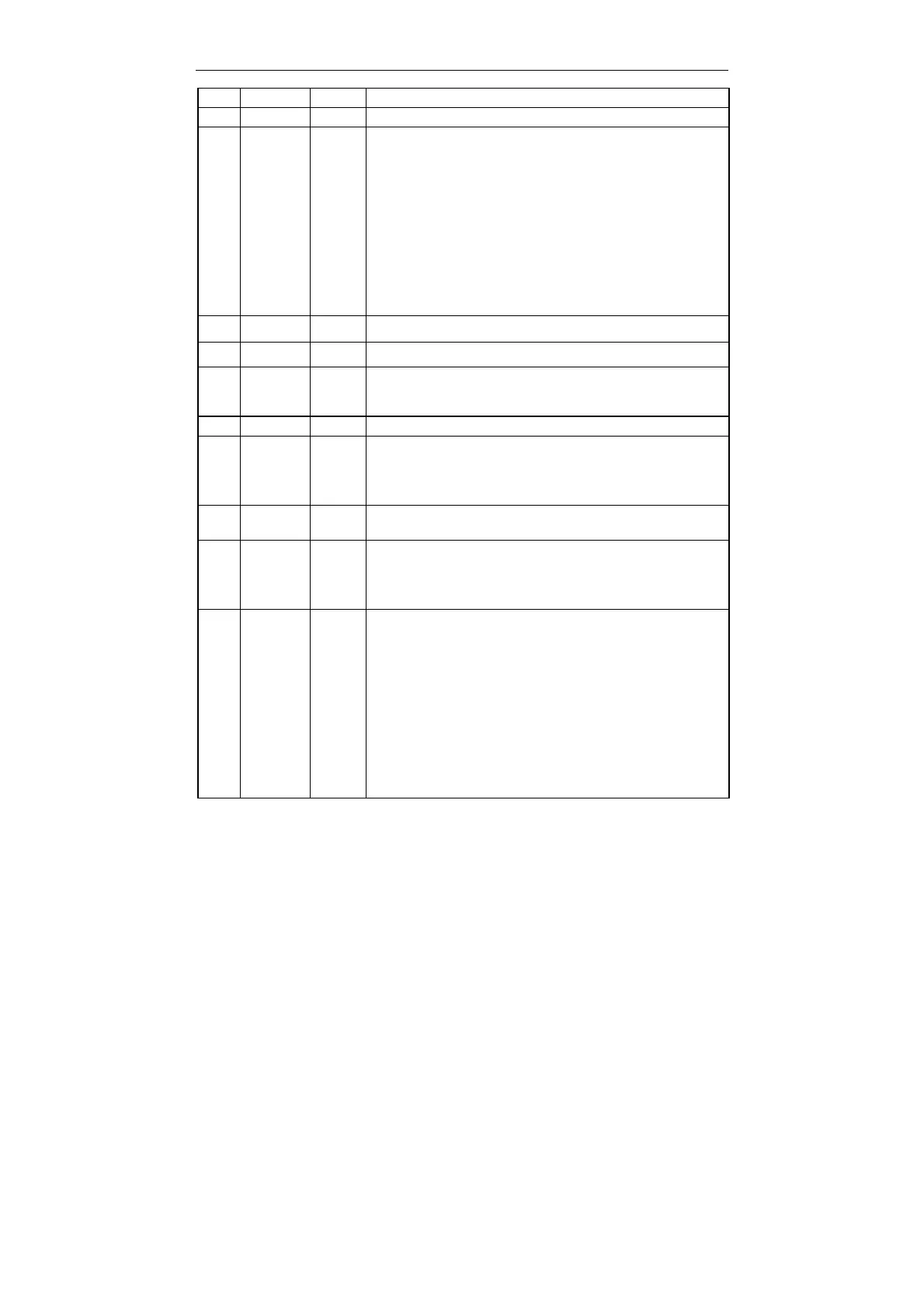

200 0/1/2 0

Trimming mode selection:

0: lockstitch machine

1: interlock machine: Needle stops at the up position and trim.

2: overlock machine: manual trimming

202

0/1/2/

3/4/5/6

1

trimming timing options:

0: 203 parameter setting angle [TS] Department to conduct a

tangent, until up needle stop after the delay time set by 206

parameter [T2] so far.

1: 203 parameter setting angle [TS] Department to conduct a

tangent, until No. 204 parameter setting angle [TE] so far.

2: 203 Number parameter setting angle [TS] Department to conduct

a tangent, set the delay time parameter 206 [T2] so far.

3: After the needle position signal delay time set by parameter No.

205 [T1] be the tangent, the delay time set by parameter 206 [T2] to

set the time so far.

Loading...

Loading...