- 70 -

7.2 Fault diagnosis

Unable to startup Rotating force of start machinery too weak No revolution in the RE Rotary Engine

•Fuse blown •Power shortage in battery •Bad act of startup clutch

•Power shortage in battery •Poor contact of connecting wire

•Reverse revolution of startup electrical machinery

•Bad acts of main switch •

Gear of the startup machinery jammed with foreign body

•Power shortage in battery

•Bad act of startup clutch

•Bad act of brake switch

•Bad act of start relay

•Poor contact of connecting wire

•Bad act of startup electrical machinery

7.3 Start electric machinery

7.3.1 Disassembly

*Note

The main switch must be switched to "OFF"

before disassembly of the startup electrical

machinery. Dismantle the bonding strip of the

battery and turn on the power supply to see

whether the startup electrical machinery will run

so as to confirm security.

First take down the wire clamp of the startup electrical machinery

Disassemble the fixing bolts on the startup electrical machinery

and unload the electrical machinery.

Roll up the rubber waterproof jacket and disassemble the joint of

startup electrical machinery.

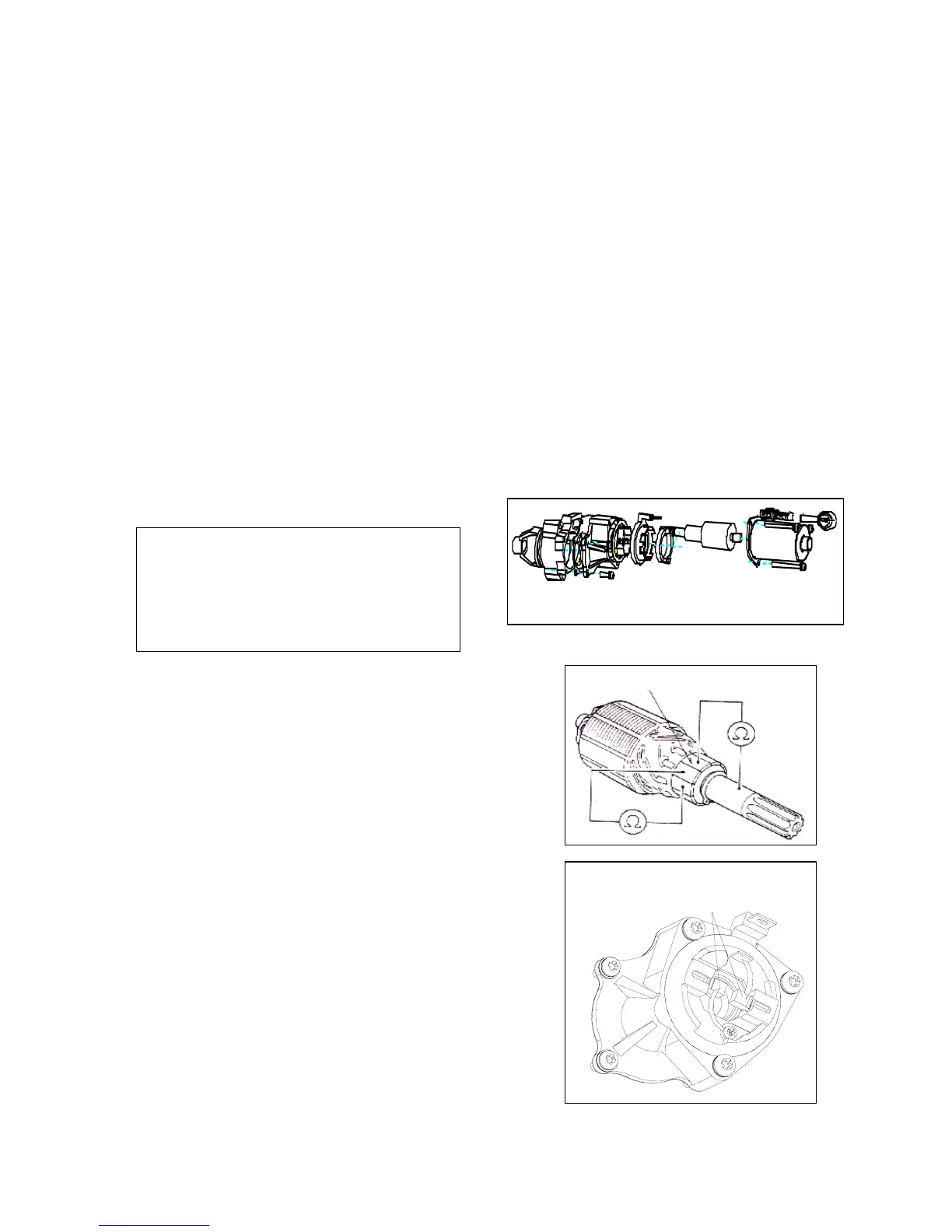

7.3.2 Dismantling

Disassemble the housing bolts, front cover, motor housing and

others.

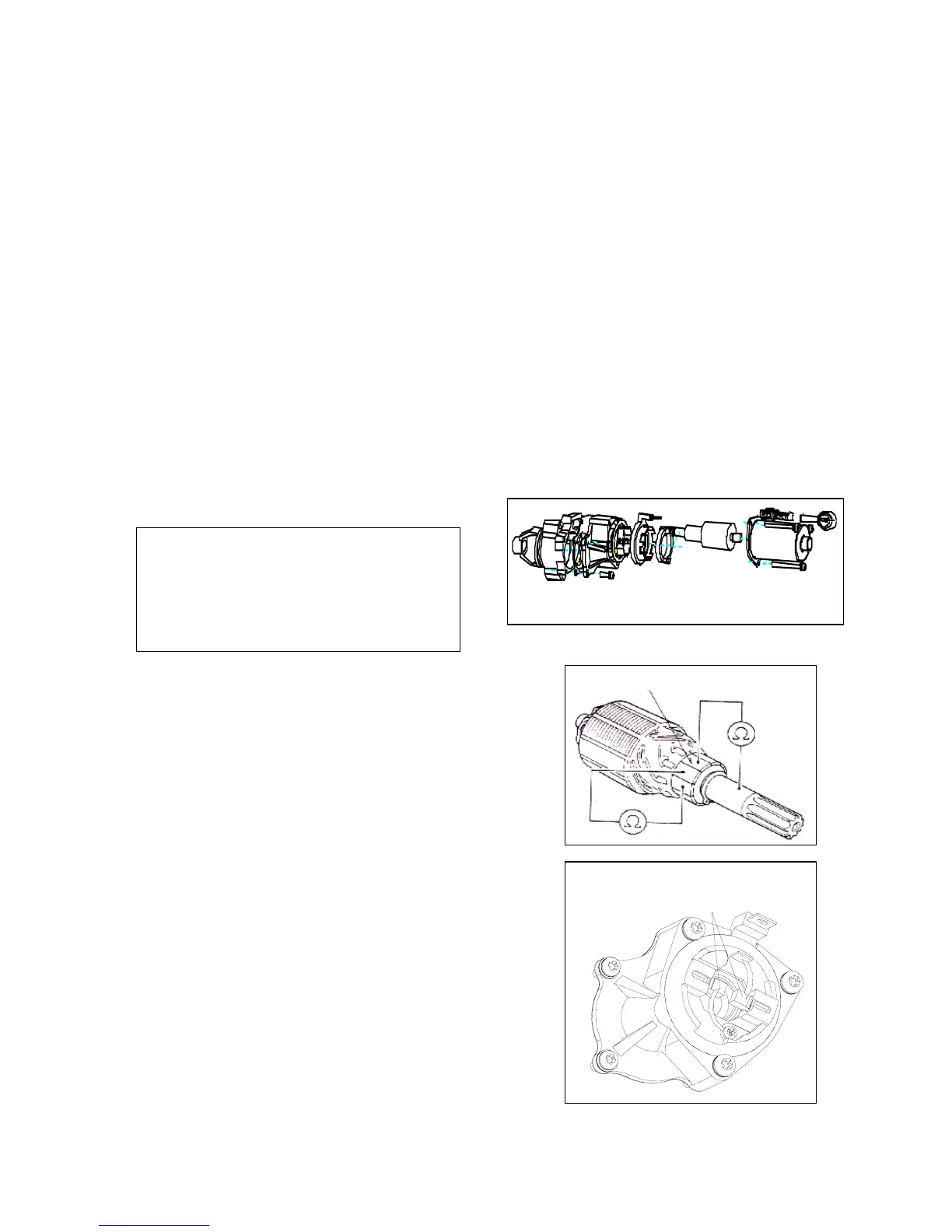

7.3.3 Inspection

Inspect other spare parts.

If uneven wear, damage or burning is detected on the surface,

replace it with a new one.

The adhesive metal powder between commuator surfaces must be

cleaned away.

电刷

electric brush

Commutator

Loading...

Loading...