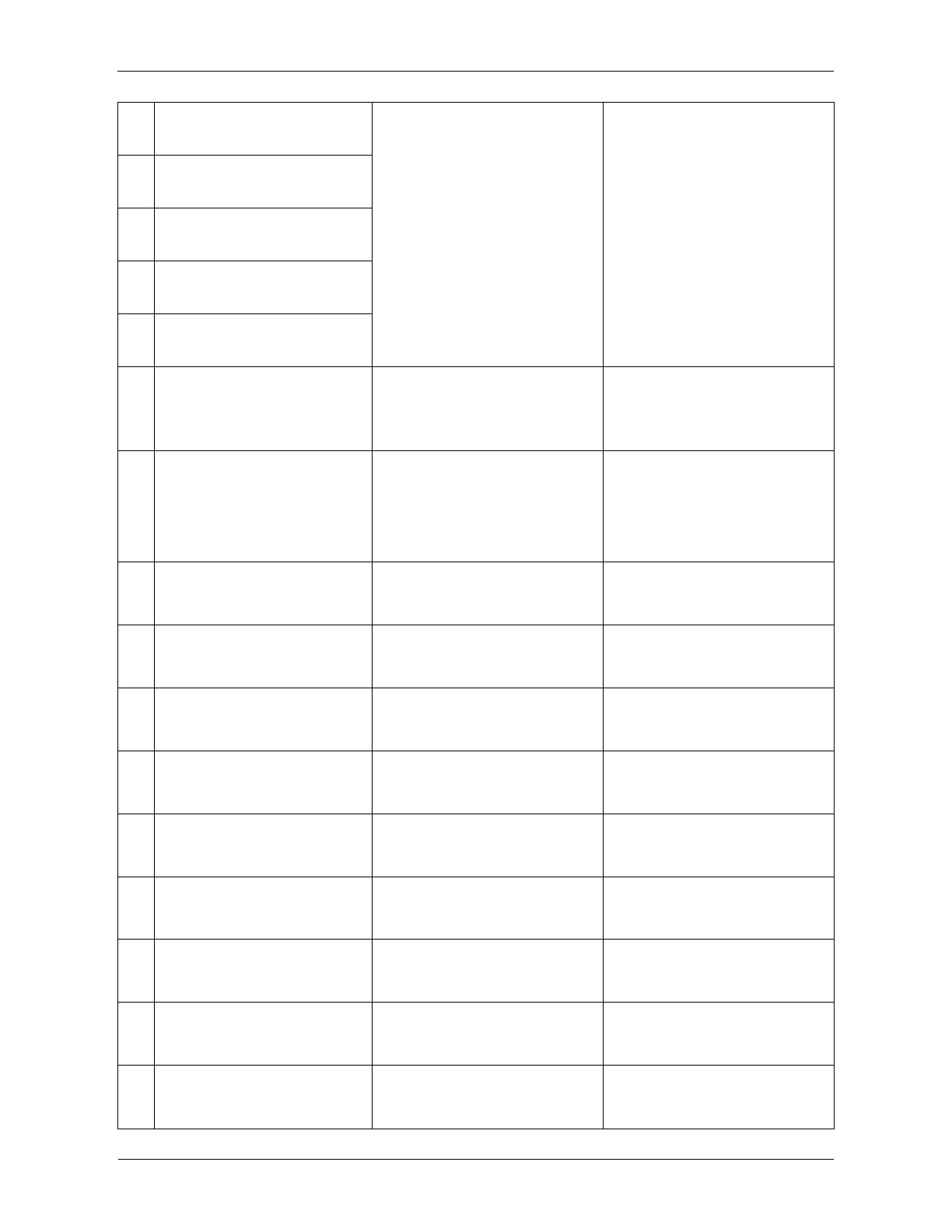

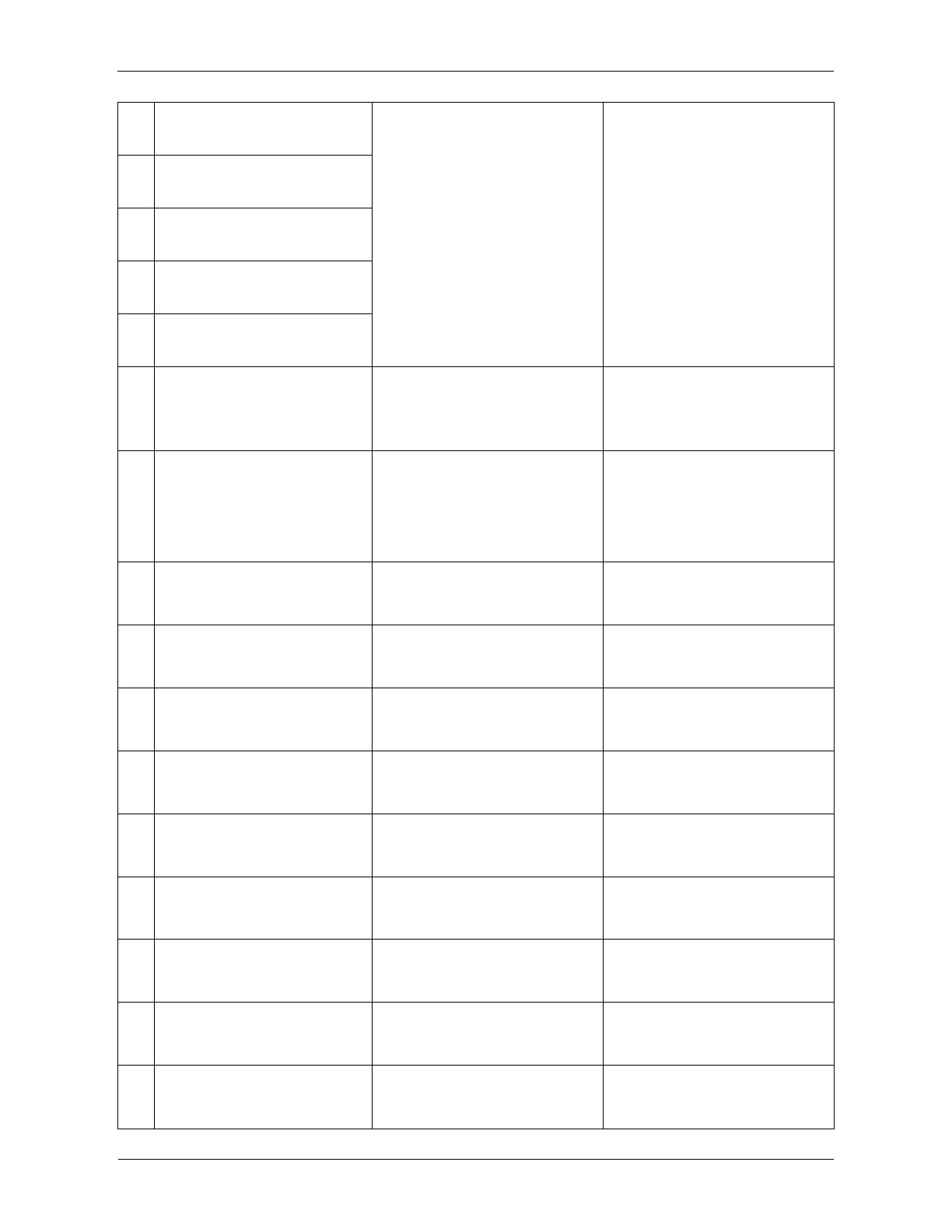

ULTIMA series ALARMS

NU_ULTIMA_02_EN_1612 54

34

ADDITIVE 1 INTAKE: UNEXPECTED

* optional ProKIT or validation monitor

A flow of product is detected outside a

product intake phase.

- Check the flowmeter.

35

ADDITIVE 2 INTAKE: UNEXPECTED

* optional ProKIT or validation monitor

36

ADDITIVE 3 INTAKE: UNEXPECTED

* optional ProKIT or validation monitor

37

ADDITIVE 4 INTAKE: UNEXPECTED

* optional ProKIT or validation monitor

** optional extra alkaline dosing pump

87

ADDITIVE 5 INTAKE: UNEXPECTED

* optional ProKIT or validation monitor

** optional extra alkaline dosing pump

50 TEMPERATURE EXCEEDS SET POINT

The temperature is higher than set point +

tolerance.

- Check the "MAXIMUM OVERHEATING"

parameter for water heating.

- Check the water inlet temperature.

- Verify the probe reads correctly.

- Verify that the steam valve is closed.

- Verify if the heating contactor is open.

51 HEATING FAULT

During the heating phase if the water

temperature has not increased by the set

minimum slope.

- Check electrical connection, state of

heating elements and safety thermal

cut-out.

- Verify that steam valve is opening

(steam heating option)

- Check the "TEMPERATURE INCREASE

TOLERANCE" parameter for water

heating.

52 COLUMN DRYING FAULT

During the heating phase the temperature

has not reached the set point within 4

minutes

- Check the heaters

- Check the probe

54

CHAMBER HEATING MAXIMUM

TEMPERATURE

The temperature is over the maximum

allowed

- Check the probe max value parameter.

- Check that the steam valve is operating

properly

- Check the probe

55

COLUMN DRYING MAXIMUM

TEMPERATURE

The temperature is over the maximum

allowed

- Check the probe max value parameter.

- Check the probe

70 HEATING : PROBE DEFECT Open wire, overrange or underrange

- Verify the probe.

- Check the wire connections.

71 COLUMN DRYING : PROBE DEFECT Open wire, overrange or underrange

- Verify the probe.

- Check the wire connections.

82 USER STOP Cycle aborted by user.

90 LOADING DOOR FAULT

The door was detected opened during cycle

or failed to close/lock on request.

- Check door closing and door switches.

97

SAMPLING TIME ELAPSED

(only for washer with sampling option)

Sampling break was not acknowledged

within the sampling alarm delay.

- Allow enough time to do the sampling.

- Acknowledge sampling when done.

98

AIR PRESSURE

(if final rinse kit (final rinse kit, includes 2

pneumatic stop valves for detergent and

acid))

Air pressure not detected

- Check the compressed air supply.

- Check PLC I/O and wiring.

Loading...

Loading...