Setup

332291P 23

Auto-Fill Shut Off

The Auto-Fill Shut Off is used for refilling the G3

reservoir in an automatic lubrication system. As fluid is

added to the reservoir, the plate valve is pushed up to

the top of the reservoir, pushing the valve pin and

closing the inlet fluid path.

When the fluid refilling path closes, the refilling line

pressurizes and brings the refilling pump to a

pressurized stall condition.

NOTE: The operator must monitor the system while

filling the reservoir to prevent overfilling.

Load Grease

To ensure optimal performance from the G3 pump:

• Only use NLGI #000 - #2 greases appropriate for

the application, automatic dispensing, and the

temperature. Consult with the machine and lube

manufacturer for details.

• Do not overfill the reservoir.

• Do not operate the G3 pump without a reservoir

attached.

Change Grease

When changing greases, always use compatible fluids

or greases.

Remote Fill with Remote Fill Manifold

The reference letters used in the following instructions

refer to FIG. 5, pages 11.

The fill valve is used to relieve pressure in the refill line

and to reset the Auto Fill Shut Off. See Fill Valve

instruction manual 333393. Graco fill valve, part no.

77X542 is available. Contact your local Graco distribu-

tor.

1. Pull out and hold the Pressure Relief Knob (T) long

enough to relieve line pressure between Fill Mani-

fold (N) and Auto-Fill Shut Off Valve (B).

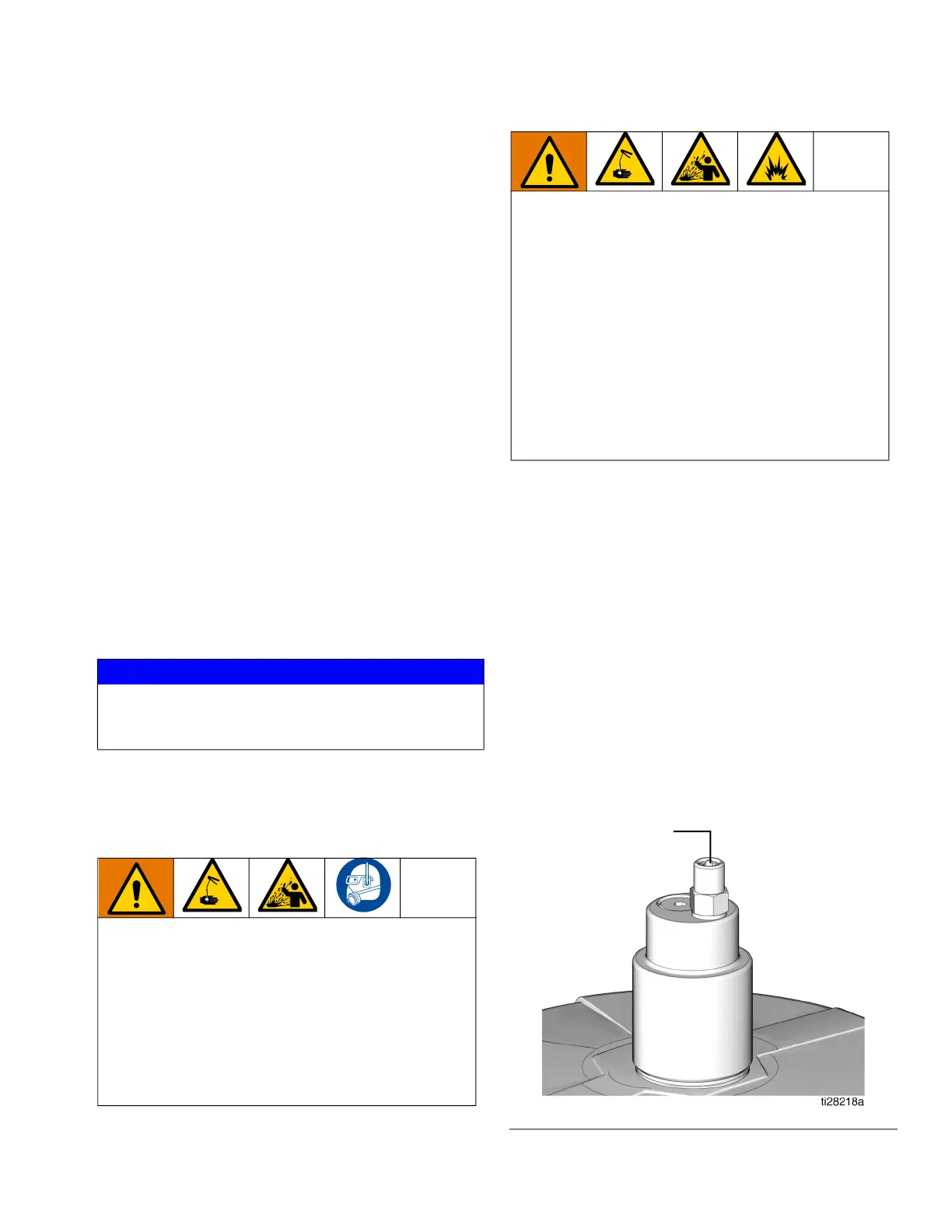

2. Verify that the Auto-Fill Shut Off (B) pin is down,

indicating it is reset (F

IG. 22).

NOTICE

Use care when filling the reservoir with a pneumatic or

an electric transfer pump, to not pressurize and break

the reservoir.

The remote filling station pump stalls (dead-heads)

when the reservoir is full, causing the supply system

pressure to rise to the maximum output pressure

of the filling station pump. To help prevent equipment

damage or serious injury caused by pressurized fluid,

such as skin injection or injury from splashing fluid,

always use a remote filling station pump with a maxi-

mum output pressure of 5100 psi (35.1 MPa,

351.6 bar) and use supply hoses with a minimum

pressure rating of 5100 psi (35.1 MPa, 351.6 bar).

COMPONENT RUPTURE HAZARD

The maximum working pressure of each component

in the system may not be the same. To reduce the

risk of over-pressurizing any component in the sys-

tem, be sure you know the maximum working pres-

sure of each component. Never exceed the

maximum working pressure of the lowest rated com-

ponent in the system. Over-pressurizing any compo-

nent can result in rupture, fire, explosion, property

damage and serious injury.

Regulate input pressure to the remote fill pump so

that no fluid line, component or accessory is over

pressurized.

FIG. 22

pin

down

Loading...

Loading...