Pump Assembly

To install a new Air Cylinder Kit:

1. Follow the Pressure Relief Procedure and turn off

the machine.

2. Disconnect the airline, remove the PR70 Shroud,

and remove the machine power entry assembly

(item 3 or Figure 40) from the machine by removing

the 2 attachment screws (4 of Figure 40).

3. Remove the 2 air valves (items 7 & 8) from the

cylinder end block (18) by removing the 3

attachment screws (2).

4. Disconnect the air cylinder piston rod (20) from the

machine drive block assembly (item 5 of Figure 39)

by removing all hex nuts (item 3 of Figure 39) from

the piston rod (additional nuts may be installed if the

machine has a hydracheck option). An open-end

wrench will be required to prevent the rod from

turning when the nuts are removed.

5. Disconnect the air cylinder from the machine frame

base assembly (item 7 of Figure 39) by removing

the 4 screws (item 8 of figure 39) which attach the

cylinder rod end block (17) to the frame. Access

the screw through the 4 holes in the blind end block

(18) using a long allen wrench.

6. Remove the air cylinder by pulling on the cylinder

from the back of the machine.

7. With the cylinder partially removed, disconnect the

airlines at the air cylinder elbow fittings (12).

8. On a bench, disassemble the air cylinder by

removing the 4 long screws (4) which connect the 2

cylinder blocks.

9. Inspect the cylinder tube (16) and piston (19) to

verify no scratches exist. Replace if necessary.

10. Using a clean dry cloth, remove any existing grease

from the inside of the tube (16), the outside of the

piston (19) and the cylinder rod (20).

11. Remove the 2 cylinder block orings (item 2 of

Figure 40) from the blocks and replace. Remove

the piston oring and replace (item 1 of Figure 40).

12. Remove the cylinder rod from the rod end block,

then remove the rod oring (item 3 of Figure 40) from

the rod end block and replace.

13. Install Graco high temperature lubricant Grease

(Graco P/N 115982) to the inside of the tube (16),

the outside of the piston (19), all the orings and the

cylinder rod (20).

14. Re-assemble the air cylinder. Attach the 2 drive

blocks by reinstalling the 4 long screws (4). Torque

the screws as specified in note

of Figure 43.

15. Reinsert the air cylinder into the back of the

machine by inserting the cylinder rod through the

hole in the base frame and in the drive block.

16. Before the cylinder is completely in place, re-

connect the airlines to the cylinder block elbows

fittings (12). Verify the correct airlines are

connected (see Figure 43).

17. Reattach the cylinder to the base frame by

reinstalling the 4 screws (item 8 of Figure 39).

18. Reattach the cylinder to the drive block by

reinstalling the hex nut (item 3 of Figure 39) to the

cylinder rod. Torque the nut as specified in note

of Figure 39.

19. Reattach the valves to the blind end block by

reattaching the 3 screws (2).

20. Reattach the power entry assembly by reinstalling

the 2 attachment screws (item 4 of Figure 40).

21. Reconnect input air into the machine. Operate the

machine accordingly, and verify no air leaks are

found. Recalibrate the machine.

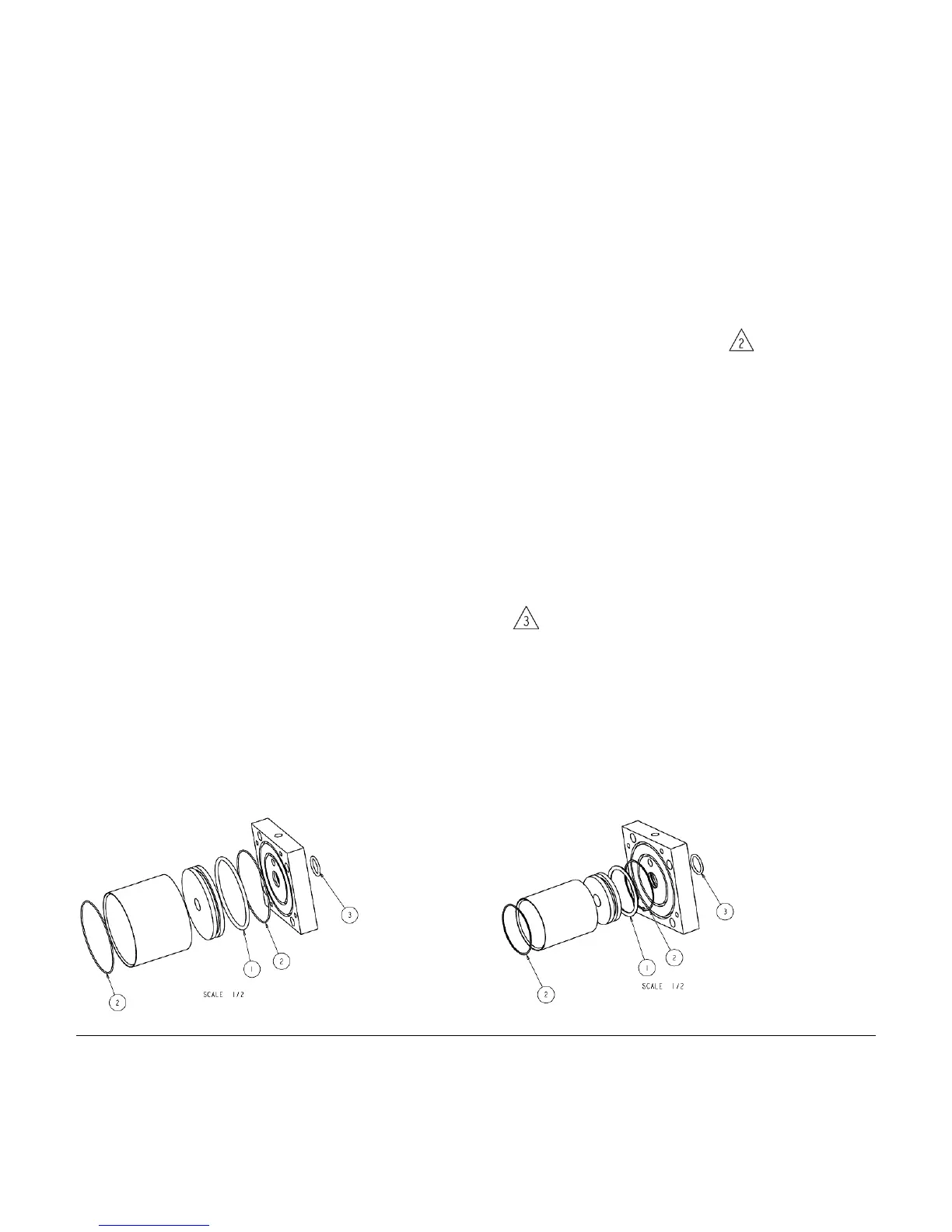

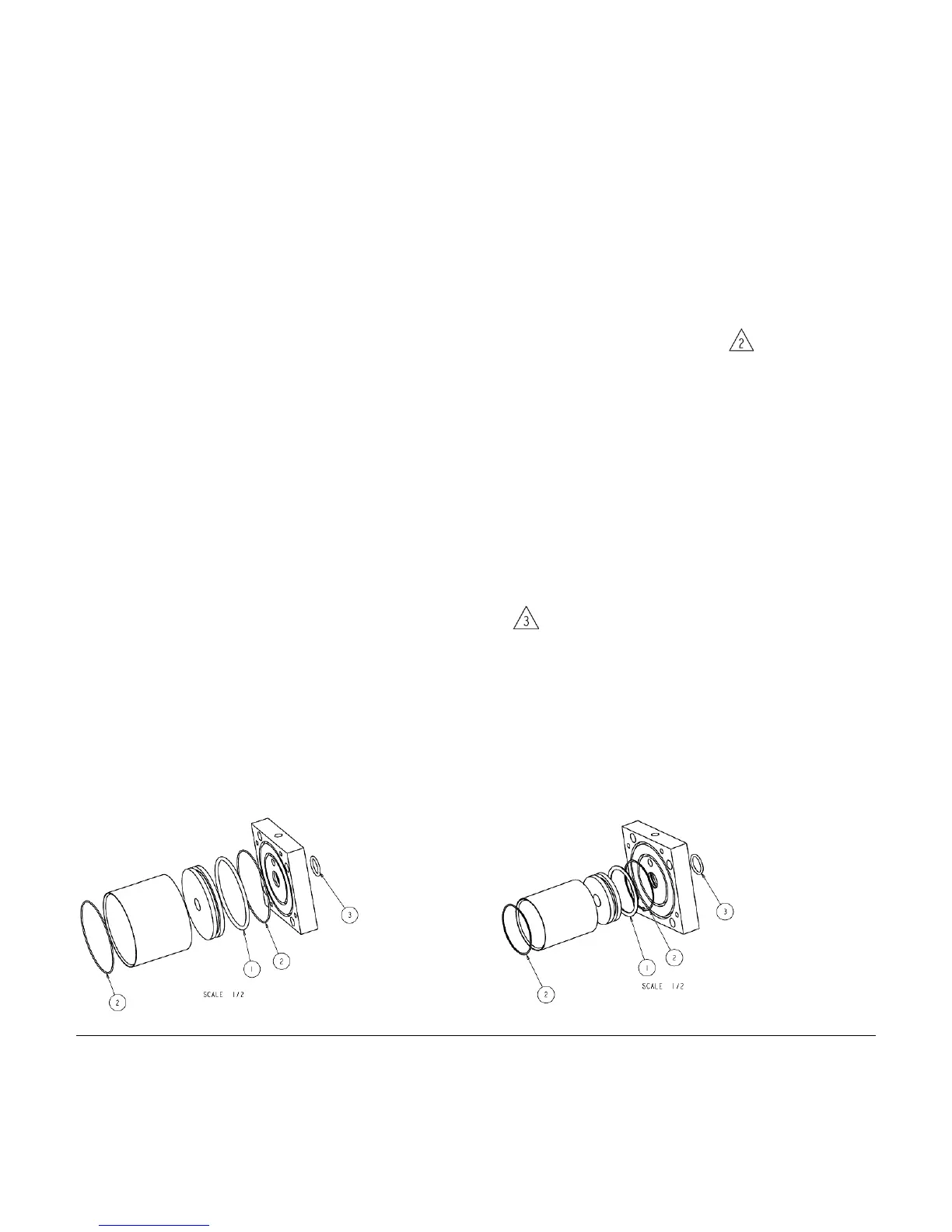

Figure 44: PR70 Air Cylinder Rebuild Kits, 4.5” and 3.0” Diameter Versions (LC0092 & LC0091).

Key:

(LC0092, 4.5” DIA. Rebuild Kit) (LC0091, 3.0” DIA. Rebuild Kit)

Ref P/N Description QTY Ref P/N Description QTY

1 104131 ORING, VIT, CDG 1 1 120875 ORING, VIT, CCE 1

2 104271 ORING, VIT, JDG 2 2 120932 ORING, VIT, JDA 2

3 107571 ORING, VIT, BAD 1 3 107571 ORING, VIT, BAD 1

312393C 37 of 52

Loading...

Loading...