Controller Connections

Connect Air Li

nes

Graco Air Controllers are labeled with the same

reference letters as the applicator, for easier

matching.

NOTICE

Use filtered air to prevent contamination of the

paint finish and to prevent damage to the air

bearing. Air that is not adequately filtered can clog

bearing air passages and cause bearing failure.

The ProBell Rotary Applicator Manual contains

detailed filtering specifications.

NOTE: For the turbine air (TA), bearing air (B),

shaping air inner (SI) and shaping air outer (SO)

lines, use 8 mm (5/16 in) OD tube with 1 mm (0.04

in) wall. For the bearing air return (BR) and the three

triggers (DT, PT, and ST), use 4 mm (5/32 in) tube.

NOTICE

Take great care to connect the air lines to the

correct ports. Incorrect air line connections will

damage the applicator.

1. Connect all nine required air lines to the

applicator first. See your applicator manual for

instructions.

2. Air Activation Signal Lines (DT, PT, ST): Connect

the lines that provide air activation signals for the

dumpvalve(DT),thepaintvalve(PT)andthe

solvent valve (ST).

3. Shaping Air Lines (SI, SO): Connect the lines

that provide the shaping air inner (SI) and the

shaping air outer (SO).

4. Turbine Air (TA), Bearing Air (B), and Bearing Air

Return (BR):

• Electronic Air Controller: Connect these air line

to the Graco speed controller (if present) or to

another air control device in your system.

• Manual Air Controller: Connect these air lines

to the ports with the matching labels.

5. Connect the main air supply line into the main air

fitting (MA, Ref. 7) on the side of the box.

NOT

E: Once the air is applied, it will flow freely

out

Port B. The controller has no option to turn

th

is air off. (Manual Controller only)

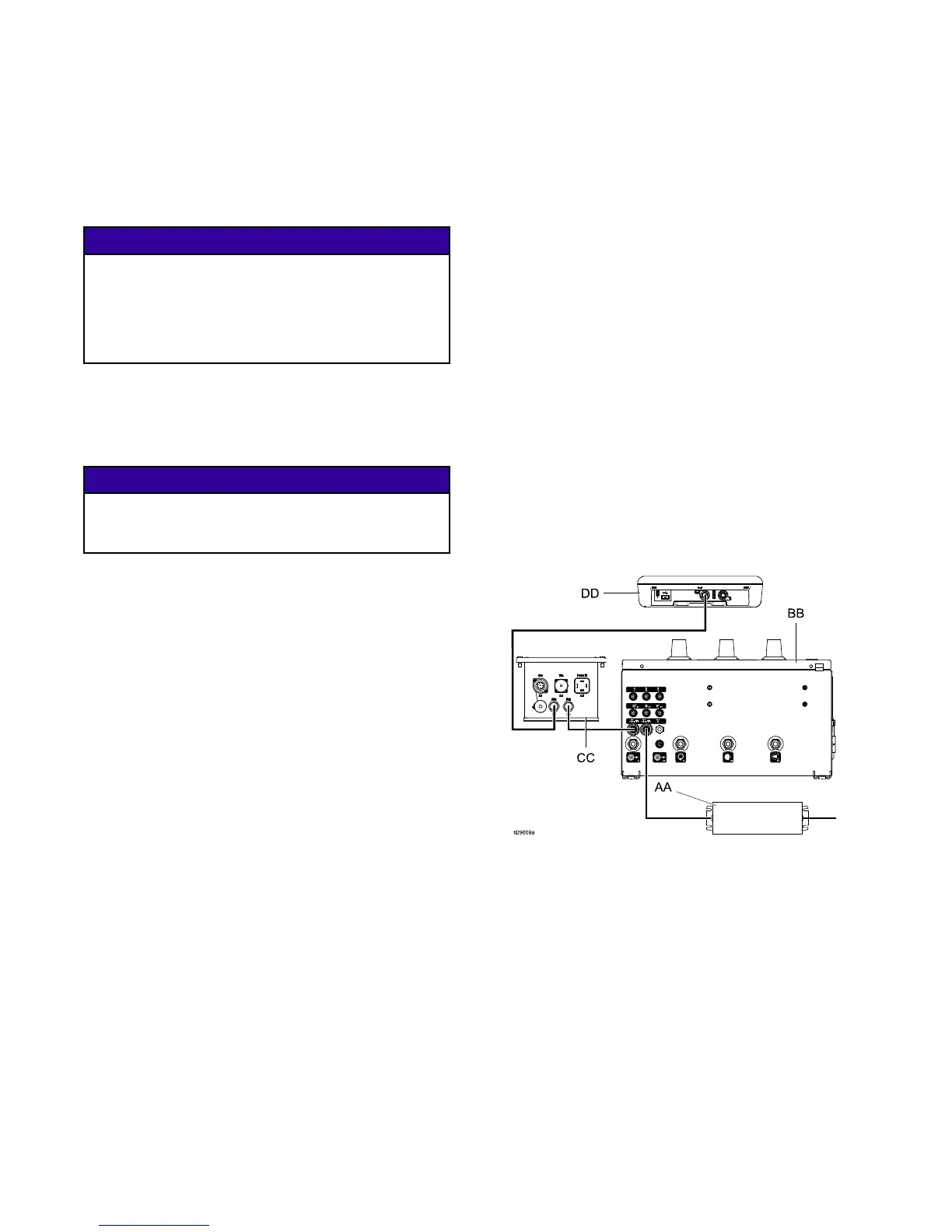

Connect Commu

nication Cables

The air controllers (Manual or Electronic)

communicate to the rest of the system over Graco

CAN cables. Each component and the power supply

must be on the Graco CAN network. The best

connection pattern depends on whether the Air

Controller is electronic or manual.

1. Connect a Gra

co CAN cable from Electrostatic

Controller

(CC) to the System Logic Controller

(DD).

2. If the power

supply is attached to the Air

Controller

, install the termination resistor (201)

on the spli

tter inside the box. NOTE: If the Air

Controlle

r was purchased as part of a system, the

terminati

on resistor will be installed at the factory.

If not, the

resistor comes with the power supply.

3. Manual Air

Controller:

a. Connect a Graco CAN cable from the power

supply (AA) to the right (inside) port on the

Air Controller (BB).

b. Connect a Graco CAN cable from the

other port on the Air Controller (BB) to the

Electrostatic Controller (CC).

4. Elec

tronic Air Controller (with Speed Controller):

a. Connect a Graco CAN cable from the power

supply (AA) to the lower/rear port on the

Speed Controller (EE)

b. Connect a Graco CAN cable from the Speed

Controller (EE) to the Air Controller (BB).

c. Connect a Graco CAN cable from the Air

Controller (BB) to the Electrostatic Controller

(CC).

1

4

3A3954B

Loading...

Loading...