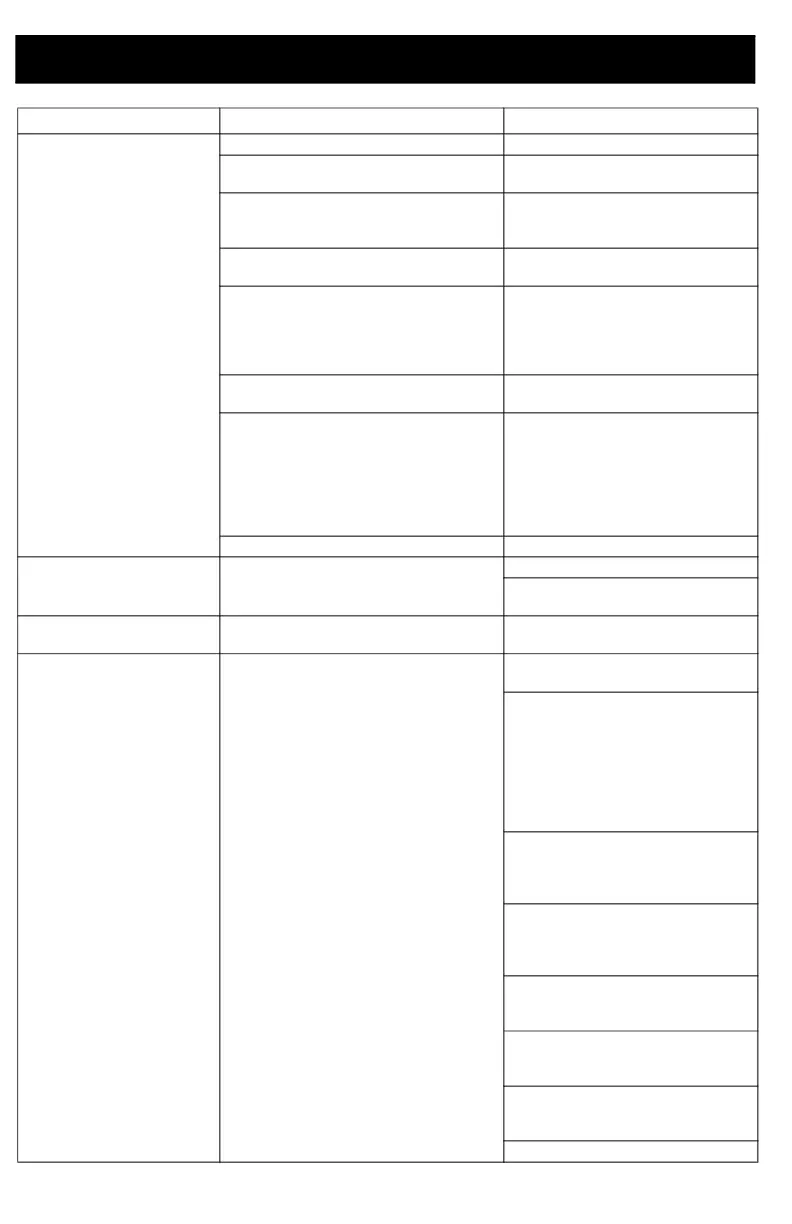

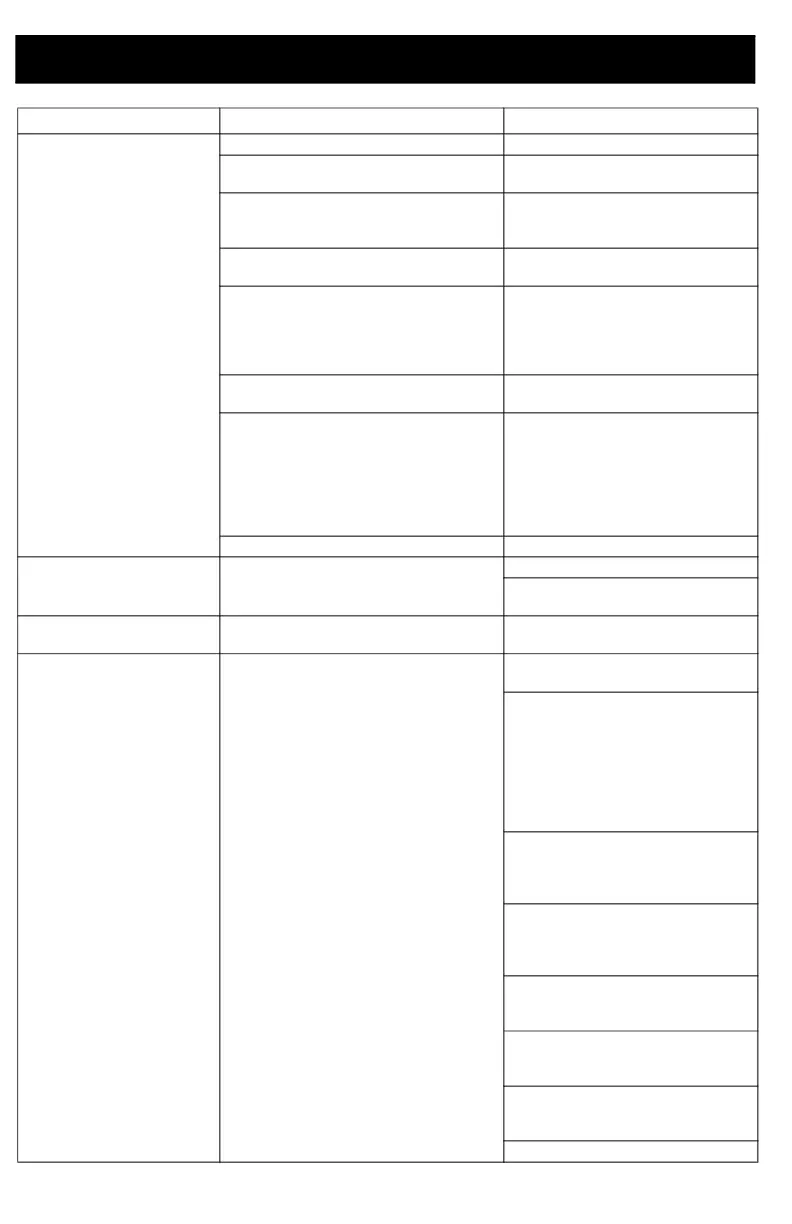

Troubleshooting

30 3A4702E

Sprayer sprays with poor

results

Spray Tip is partially clogged. See Clear Tip Clogs, page 19

.

Spray Tip is not in correct position Rotate Spray Tip to SPRAY

position.

Incorrect Spray Tip for application of

material.

Install different size Spray Tip.

See Tip Selection Chart, page

16.

Spray Tip is worn or damaged Replace Spray Tip. See

Reference, page 25.

Material being sprayed is aerated

because it was shaken.

Do NOT shake material. Stir the

material or check the

manufacturer’s

recommendation for the

material being sprayed.

Material being sprayed is too cold to

spray.

Warm material.

Outlet valves are dirty or worn. Remove two pump plugs and

front valve to gain access to the

three outlet valves. Clean outlet

valves. Outlet valves are not

installed properly. See

Cleaning Outlet Valves, page

26. Replace if necessary.

Pump has reached the end of its life. Replace pump assembly.

Sprayer runs

intermittently or very

slow

Fluid has gotten into the sprayer. Allow the sprayer to dry out.

Replace motor and/or

Smartcontrol with enclosure.

Pump will spray paint but

will not spray water

Pump has reached the end of its life. Replace pump assembly.

Paint leaks out of the cup

threads.

Cup not properly seated. Make certain that there is only

one FlexLiner in Cup Support.

Make certain the cup cover is

properly threaded to the Cup

Support. If threads are visible

below the Cup Support when

tight, fully remove the cup cover

and reinstall to the Cup Support

so no threads are visible when

tight.

Make certain the cup cover is

tightened to Cup Support. For

proper sprayer operation lid

must seal tightly with the cup.

Avoid flexing or pushing on the

Cup Support when you

evacuate the air out of the

FlexLiner.

Avoid pulling down on the

FlexLiner when you evacuate

the air out of the FlexLiner.

Make certain there is no

damage to the FlexLiner lip or

the cup cover gasket.

Make certain that the FlexLiner

lip and cup cover gasket is free

of debris and dried paint.

Replace FlexLiner.

Problem Cause Solution

Loading...

Loading...