Troubleshooting

Pumps Do Not Reverse Direction

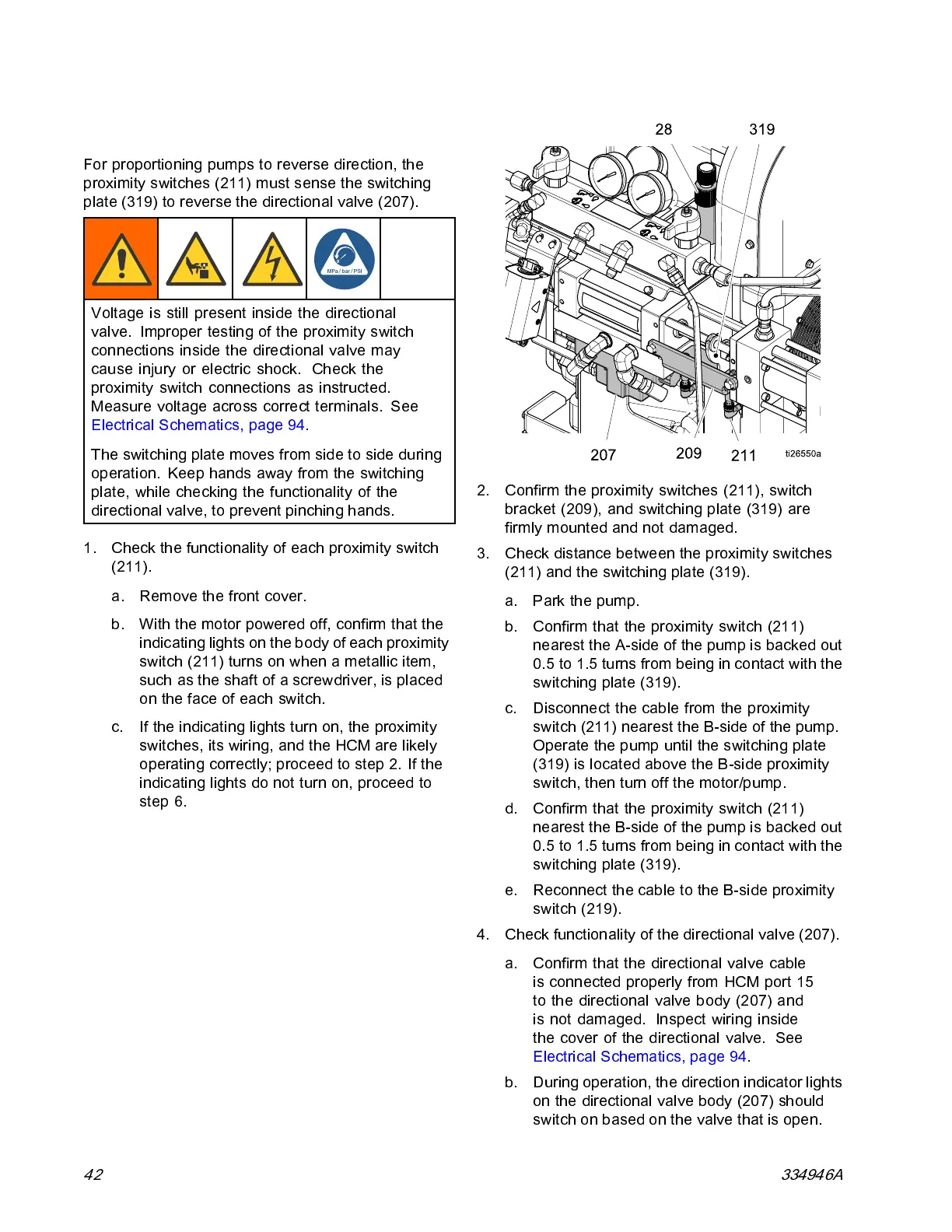

For proportioning pumps to reverse direction, the

proximity switches (211) must sense the switching

plate (319) to reverse the directional valve (207).

Voltage is still present inside the directional

valve. Improper testing of the proximity switch

connections inside the directional valve may

cause injury or electric shock. Check the

proximity switch connections as instructed.

Measure voltage across correct termi nals. See

Electrical Schem atics, page 94.

The switching plate moves from side to side during

operation. Keep hands away from the switching

plate, while checking the functionality of the

directional valve, to prevent pinching hands.

1. Check the functionality of each proximity switch

(211).

a. Remove t

he front cover.

b. With the

motor powered off, confirm that the

indicat

ing lights on the body of each proximity

switch (

211) turns on when a metallic item,

such as t

he shaft of a screwdriver, is placed

on the f

ace of each switch.

c. If the i

ndicating lights turn on, the proximity

switch

es, its wiring, and the HCM are likely

opera

ting correctly; proceed to step 2. If the

indic

ating lights do not turn on, proceed to

step 6

.

2. Confirm the proximity switches (211), switch

bracke t (209), and switching plate (319) are

firmly mounted and not damaged.

3. Check distance between the proximity switches

(211) and the switching plate (319).

a. Park the pump.

b. Confirm that the proximity switch (211)

nearest the A-side of the pump is backed out

0.5 to 1.5 turns from being in contact with the

switching plate (319).

c. Disconnect the cable from the proximity

switch (211) nearest the B-side of the pump.

Operate the pump until the switching plate

(319) is located above the B-side proximity

switch, then turn off the motor/pump.

d. Confirm that the proximity switch (211)

nearest the B-side of the pump is backed out

0.5 to 1.5 turns from being in contact with the

switching plate (319).

e. Reconnect the cable to the B-side proximity

switch (219).

4. Check functionality of the directional valve (207).

a. Confirm that the directional valve cable

is connected properly from HCM port 15

to the directional valve body (207) and

is not damaged. Inspect wiring inside

the cover of the directional valve. See

Electrical Schematics, page 94.

b. During op eration, the direc tion indicator l ights

on the directional valve body (207) should

switch on based on the valve that is open.

42

334946A

Loading...

Loading...