Setup

Grounding

The equipment must be grounded to reduce the

risk of static sparking and e lectric shock. Electric

or static sparking can cause fumes to ignite or

explode. Improper grounding can cause electric

shock. Grounding p rovides an esc ape wire for the

electric current.

•

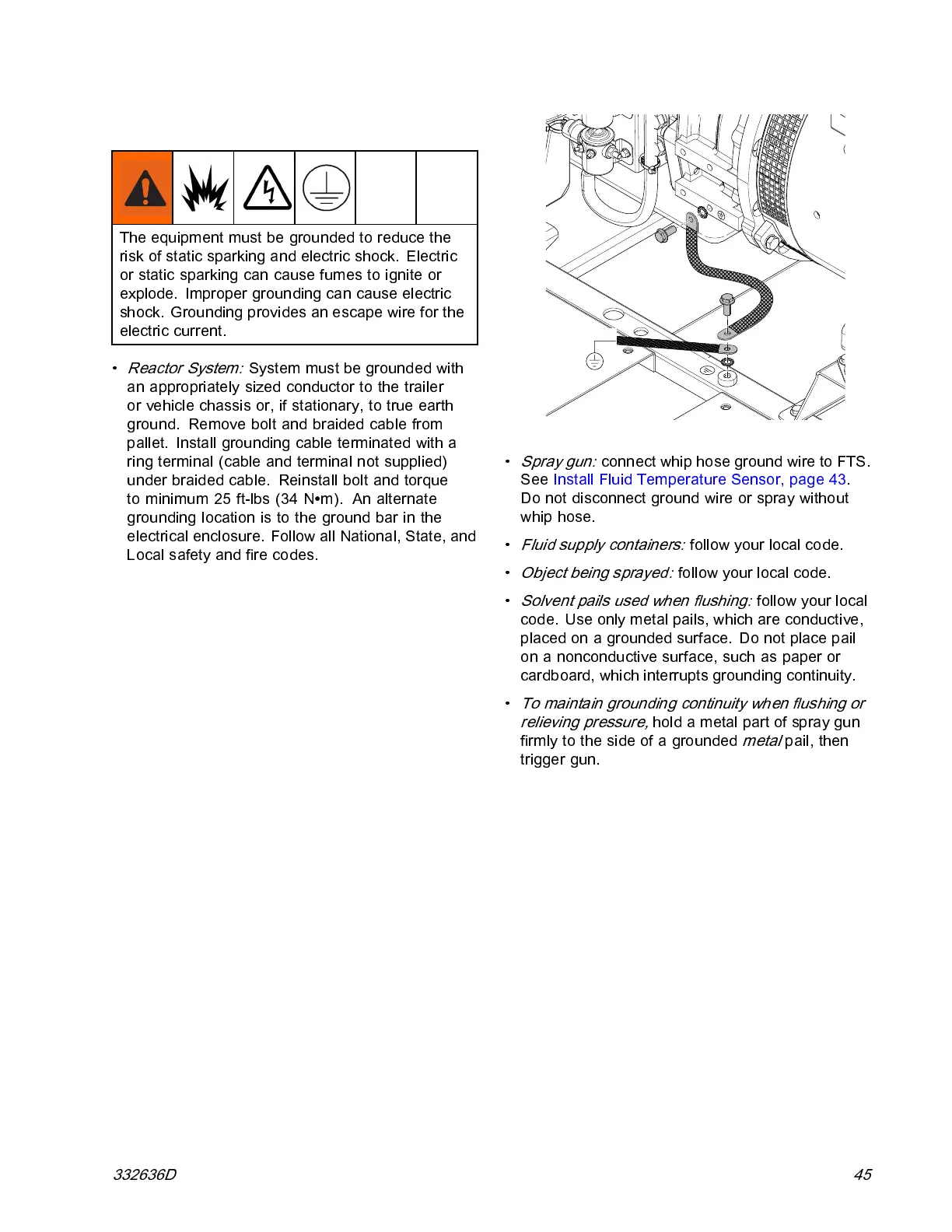

Reactor Sys tem:

System must be grounded with

an appropriately s ized conductor to the traile r

or vehicle chassis or, if stationary, to true earth

ground. Remove bolt and braided cable from

pallet. Install grounding cable terminated wi th a

ring te rminal (cab le and terminal n ot supplied)

under b raided cab le. Reinstall bolt and torque

to minimum 25 ft-lbs (34 N∙m). An alternate

grounding location is to the ground bar in the

electrical enclosure. Follow all National, State, and

Local safety and fire codes.

•

Spray gun:

connect whip hose ground wire to FTS.

See Install Fluid Temperature Sensor, page 43.

Do not disconnect ground wire or spray without

whip hose.

•

Fluid supply containers:

follow your local code.

•

Object being sprayed:

follow your local code.

•

Solvent pails used when flushing:

follow your local

code. Use only metal pails, which are conductive,

placed on a grounded surface. Do not place pail

on a nonconductive surface, such as paper or

cardboard, which interrupts grounding continuity.

•

To maintain grounding c ontinuity when flushing o r

relieving pressure,

hold a metal part of sp ray gun

firmly to the si de o f a ground ed

metal

pail, then

trigger gun.

332636D 45

Loading...

Loading...