Repair

3A1570V 27

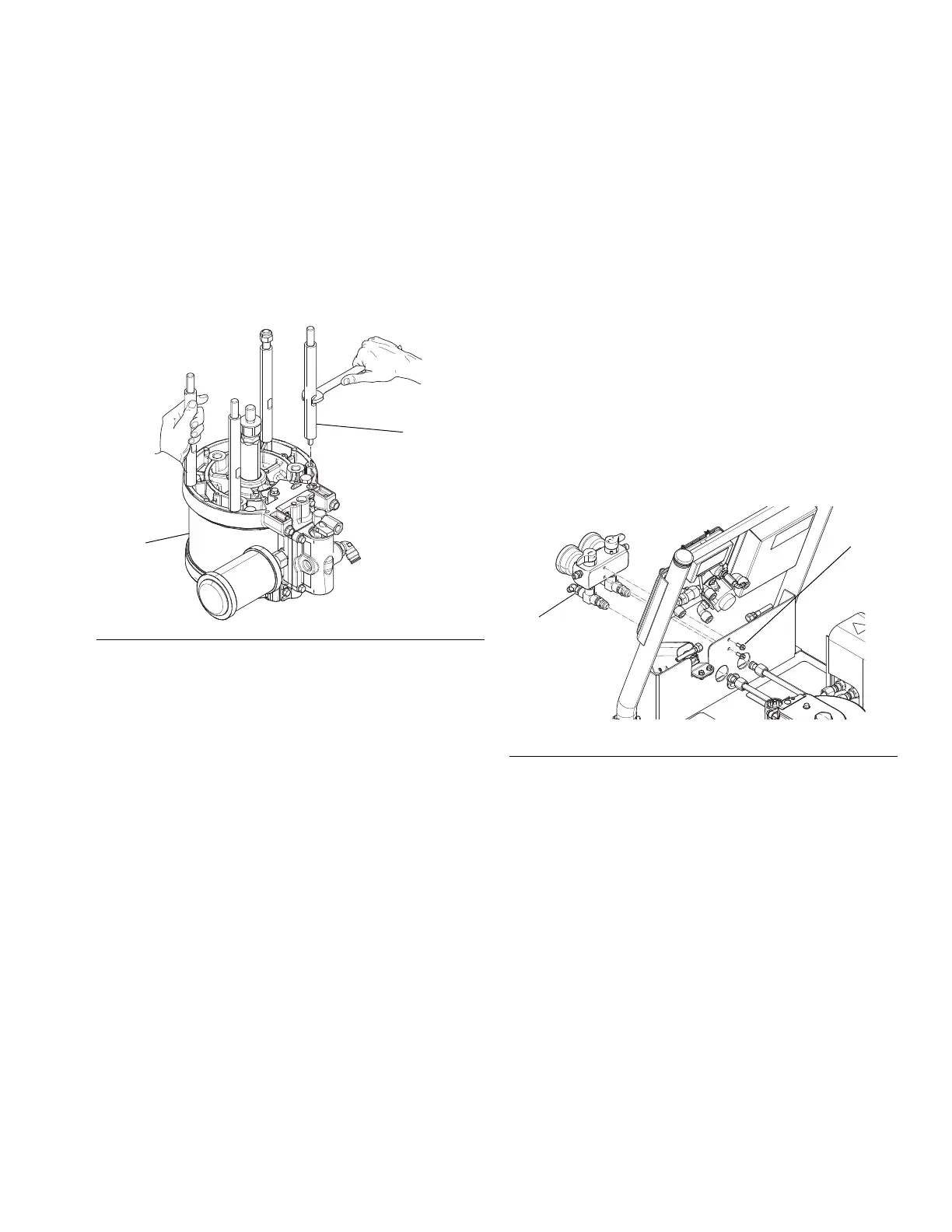

5. Loosen two screws (314) behind air motor bracket.

Carefully lift air motor and tie rods away from the

proportioner frame and plate (301).

6. Lay air motor on a clean flat work space. Place a

wrench on the tie rod flats (309) and hold one of

other tie rods with your hand to keep the air motor

(308) in place. Remove the tie rods from the air

motor.

7. Use a wrench to hold the piston rod in place and

remove the adapter (315) with another wrench. See

F

IG

. 1.

8. See air motor manual for repair instructions.

Install Air Motor

1. Apply medium blue thread lock on adapter (315).

Use a wrench to hold the piston rod in place and

install the adapter (315) with another wrench.

Torque to 32-38 ft-lbs (43-51 N•m). See F

IG

. 1.

2. Install tie rods (309) in the bottom of the air motor

(308). See F

IG

. 3.

3. Install tie rods through plate (301). Ensure screws

(314) fit in the bracket slots (311). Install screws

(314). See F

IG

. 2.

4. Tighten nut (313) to 32-38 ft-lbs (43-51 N•m).

5. Evenly torque four tie rod nuts (310) in small

increments to 27-32 ft-lbs (37-43N•m). See F

IG

. 2.

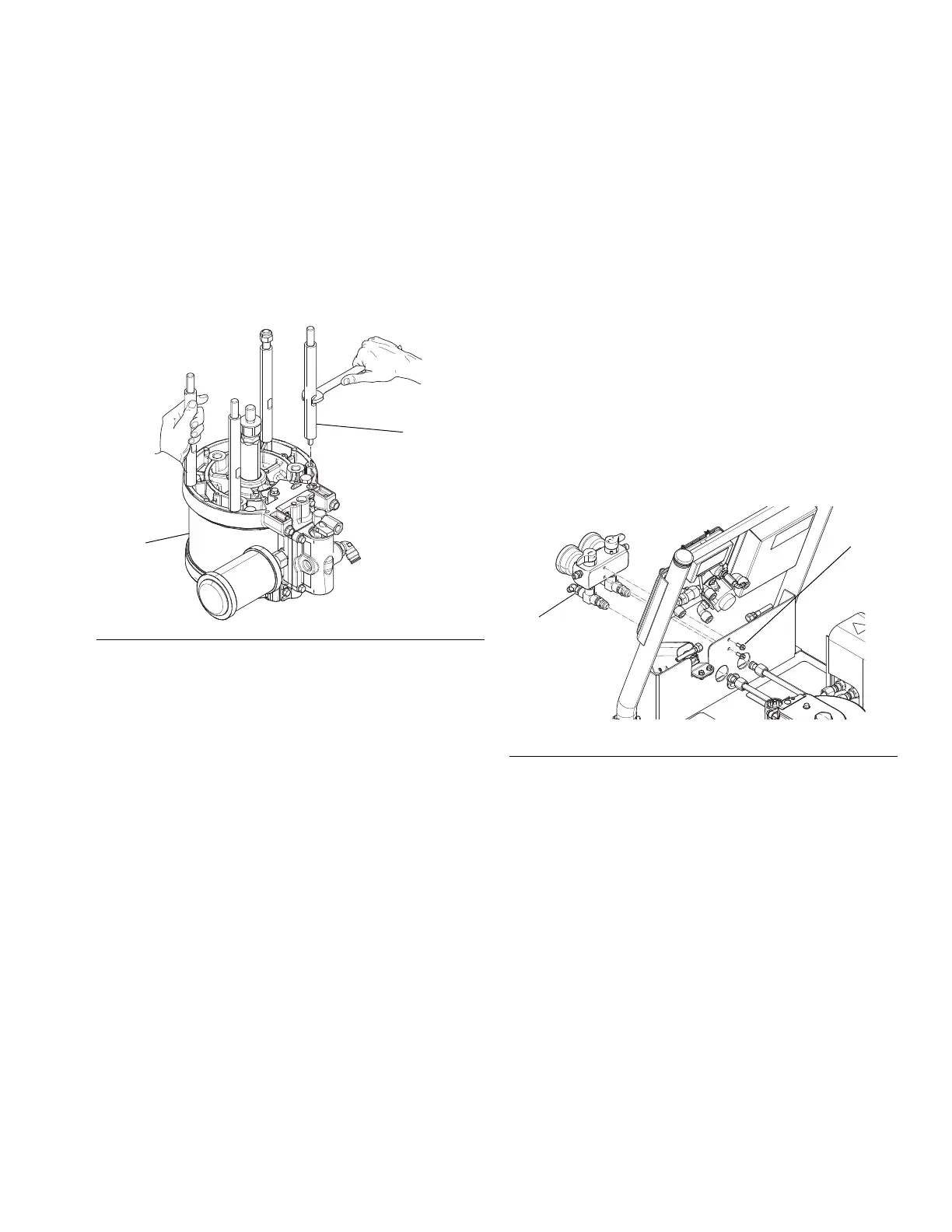

Recirculation / Over Pressure

Relief Block

Valves can be serviced with the block on the machine

(see Fluid Manifold, page 50 for parts view). For

thorough cleaning, remove the block assembly as

follows.

1. Disconnect two fluid tubes connected to back of

recirculation block (3).

2. Loosen and remove two screws (10) in back of

recirculation block.

3. See Fluid Manifold, page 50. Clean and inspect all

parts for damage. Ensure that the seat (8a) and

gasket (8b) are positioned inside each valve

cartridge (8).

4. Apply PTFE pipe sealant to all tapered pipe threads

before reassembling.

5. Reassemble in reverse order, following all notes in

Fluid Manifold, page 50.

F

IG

. 3

F

IG

. 4

Loading...

Loading...