Repair

312063Z 27

Flushing

• Flush out old fluid with new fluid, or flush out old

fluid with a compatible solvent before introducing

new fluid.

• Use the lowest possible pressure when flushing.

• All fluid components are compatible with common

solvents. Use only moisture-free solvents.

• To flush feed hoses, pumps, and heaters separately

from heated hoses, set PRESSURE

RELIEF/SPRAY valves (SA, SB) to PRESSURE

RELIEF/CIRCULATION . Flush through bleed

lines (N).

• To flush entire system, circulate through gun fluid

manifold (with manifold removed from gun).

• To prevent moisture from reacting with isocyanate,

always leave the system dry or filled with a

moisture-free plasticizer or oil. Do not use water.

Proportioning Pumps

NOTE: See your proportioning pump manual for repair

instructions.

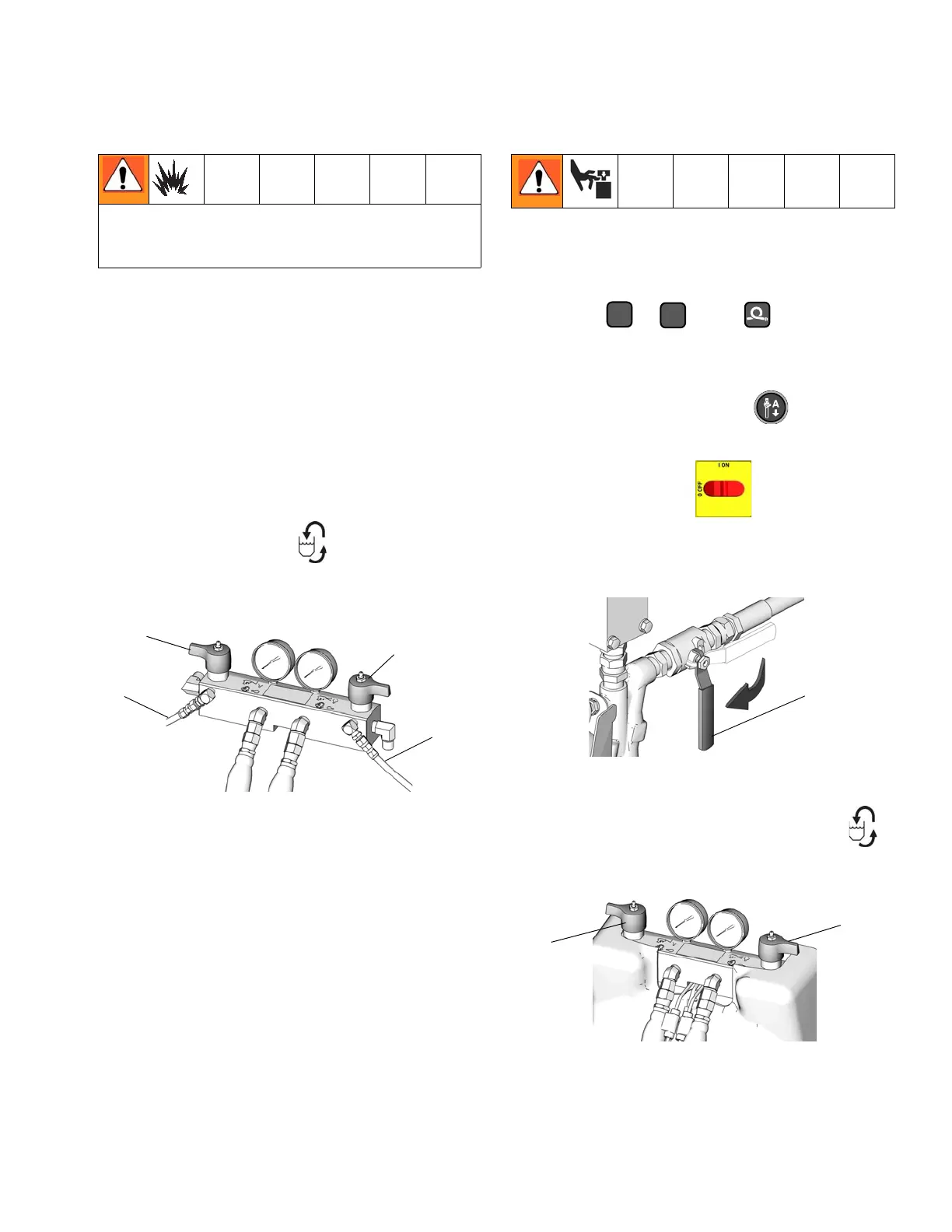

1. Shut off , , and heat zones.

2. Flush, page 27.

3. If pumps are not parked, press . Trigger gun

until pumps stop.

4. Turn main power OFF . Disconnect power

supply.

NOTE: Use drop cloth or rags to protect Reactor and

surrounding area from spills.

Flush equipment only in a well-ventilated area. Do not

spray flammable fluids. Do not turn on heaters while

flushing with flammable solvents.

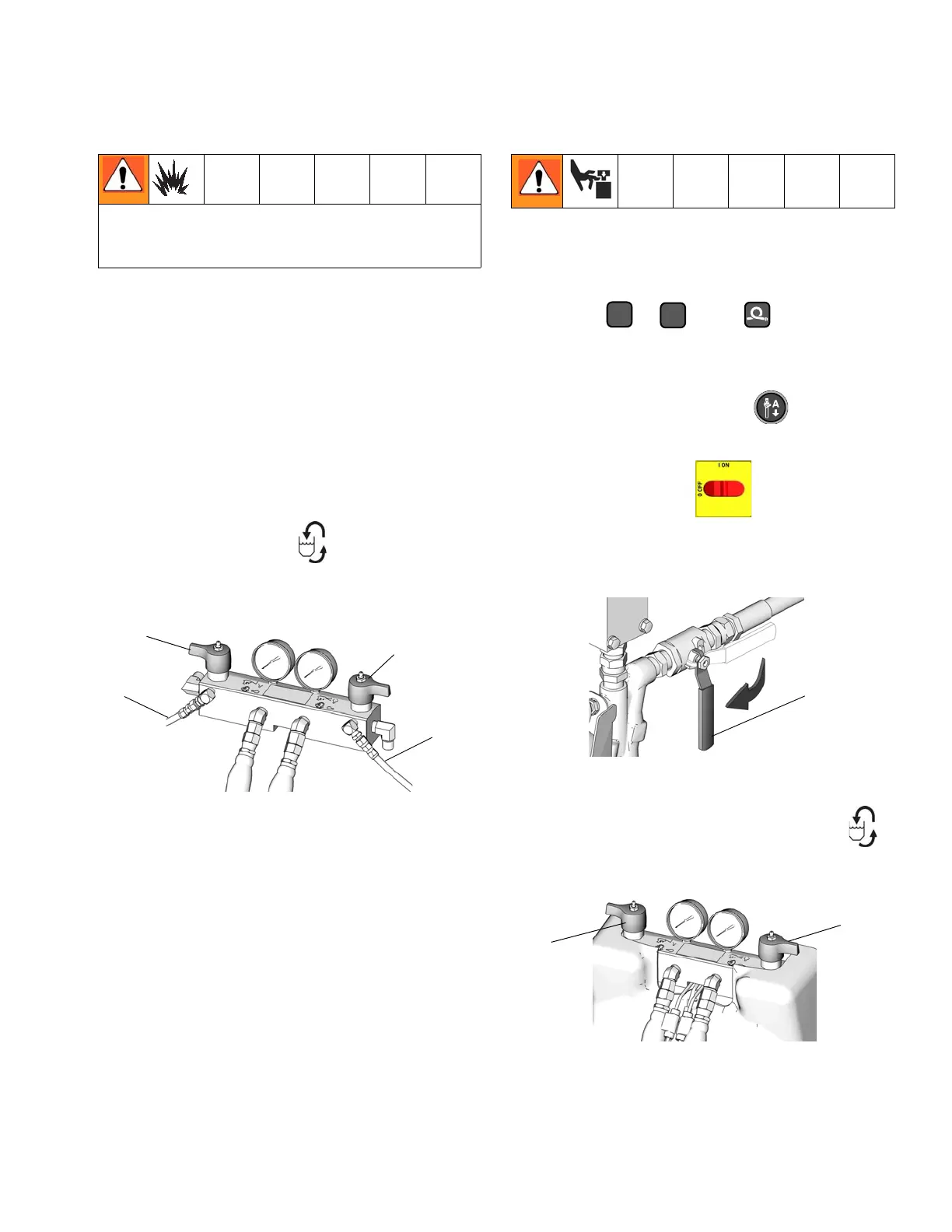

5. Shut off both feed pumps. Close both fluid inlet ball

valves (B).

6. Turn both PRESSURE RELIEF/SPRAY valves (SA,

SB) to PRESSURE RELIEF/CIRCULATION .

Route fluid to waste containers or supply tanks.

Ensure gauges drop to 0.

Loading...

Loading...