Reassemble the Air Motor and the Pump Lower

311882U 21

Reassemble the Air Motor and the Pump Lower

To reassemble the pump lower and air motor, reverse

the steps on the preceding pages. Follow the torque

requirements listed in the Parts - Model 295616

drawing on page 22.

NOTE: See Repair the Air Motor, page 16, step 4 and

step 5 (F

IG. 12) for special notes on reassembly.

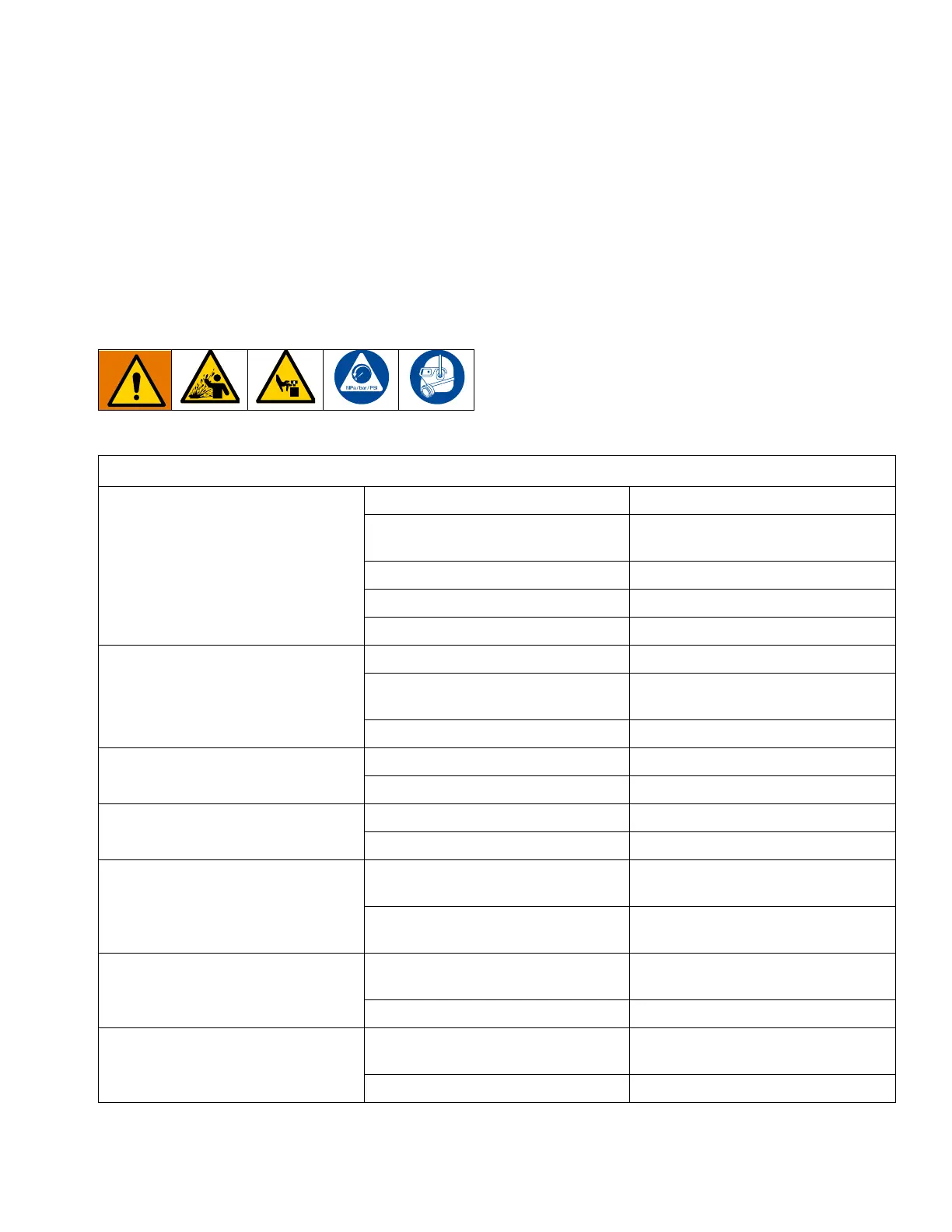

Troubleshooting

1. Follow Pressure Relief Procedure, page 14,

before checking or repairing pump.

2. Check all possible problems and causes before

disassembling pump.

Problem Cause Solution

The pump fails to operate Dirty or worn air motor. Clean, service

Inadequate air supply or restricted

lines.

Clean lines or increase the air

supply (see Technical Data).

Closed or clogged air valves. Open or clear the valves.

Clogged fluid hose or valve. Clear the hose or valves

Worn or damaged valves or seals. Service the valves or seals.

The pump operates, but the output

is low on both strokes.

Clogged fluid hose or valve. Clear the hose or valves.

Exhausted fluid supply. Refill the fluid supply and reprime

the pump.

Worn or damaged valves or seals. Service the valves or seals.

The pump operates, but the output

is low on the downstroke.

Held open or worn intake valve. Clear or service the valve.

Worn or damaged valves or seals. Service the valves or seals.

The pump operates, but the output

is low on the upstroke.

Held open or worn piston valve. Clear or service the valve.

Worn or damaged valves or seals. Service the valves or seals.

Erratic or accelerated operation. Exhausted fluid supply. Refill the fluid supply and reprime

the pump.

Broken air motor compression

spring.

Replace the spring.

Pump slowly moves after fluid

shutoff in downstroke.

Clogged or dirty intake valve check

ball.

Clean ball and seat.

Worn or damaged valves or seats. Install repair kit.

Pump slowly moves after fluid

shutoff in upstroke.

Clogged or dirty lower piston ball or

seat.

Clean ball and seat.

Worn or damaged valves or seats. Install repair kit.

Loading...

Loading...