25

Never make adjustments with the

engine running.

LOSS OF POWER IN THE

DRIVE

SYSTEM

Check the fl uid level and make sure the proper

amount of fl uid is in the reservoir. The cooling

fi ns and fan blades should be clean and free

of foreign matter.

NO POSITIVE NEUTRAL POSITION

If drive wheels travel forward or backward

when the steering lever is in swing-out posi-

tion (neutral), adjustment is required.

NEUTRAL ADJUSTMENT

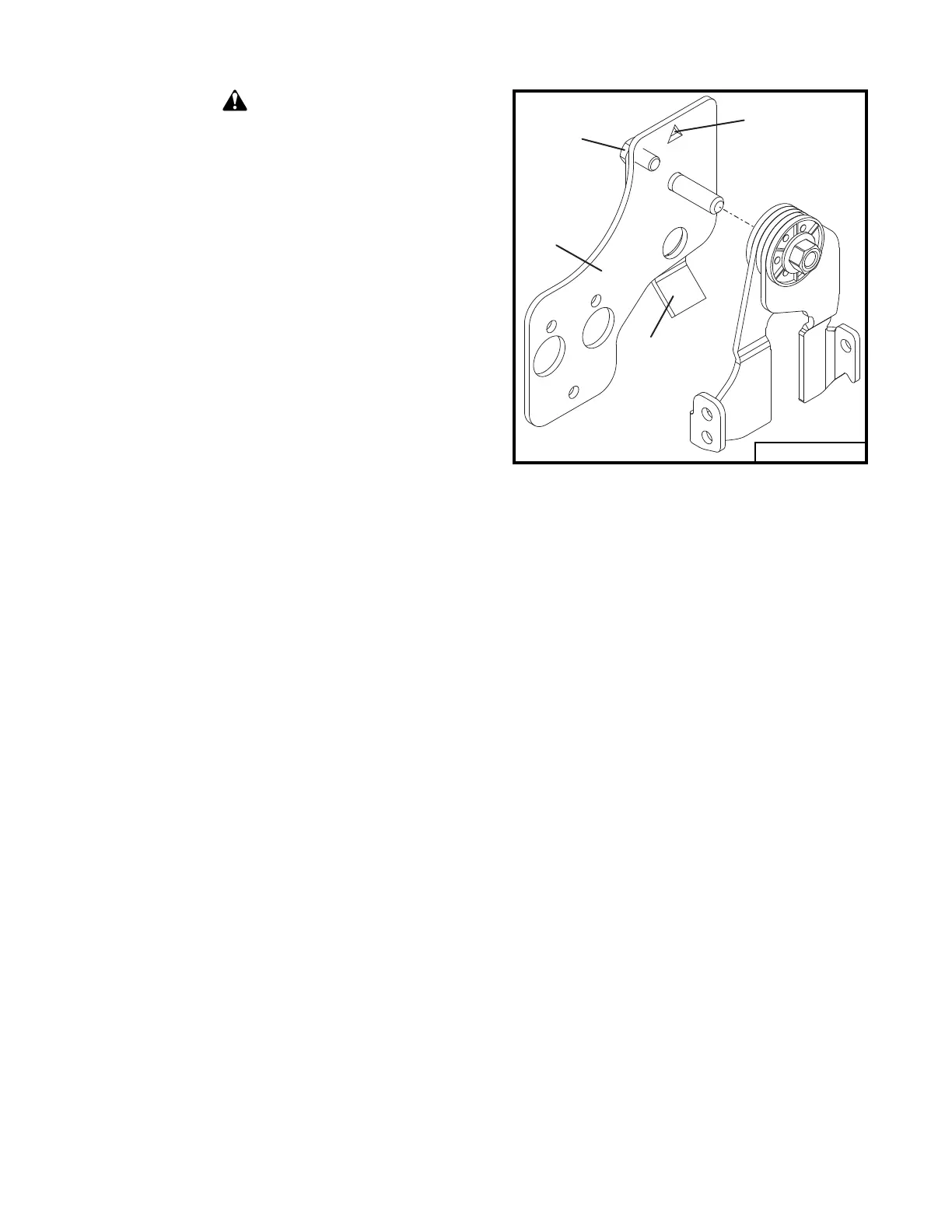

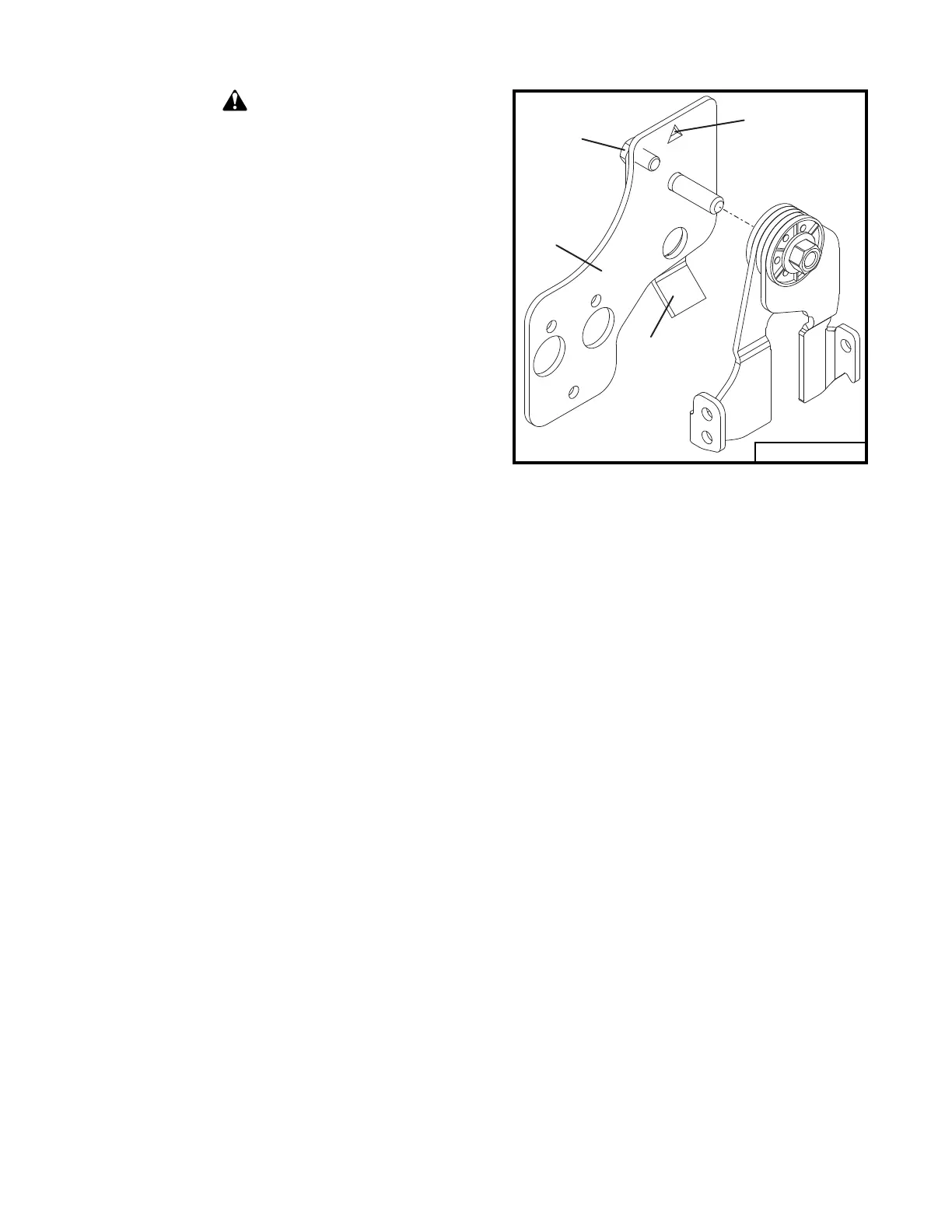

(Refer to Fig. 6 and illustration page on 37)

1. Block up under tractor frame so both drive

wheels are off the ground.

2. Make sure parking brake is released.

3. Remove linkage rod (item 28 or 29) from

transmission control arm (item 16 or 17).

4. Place steering levers in the neutral swing-

out position and start engine.

5. If either of the drive wheels turn, proceed

with the following adjustment.

6. Locate the return mount (item 37) with

the adjustment plate (item 71) bolted to it.

The right plate adjusts the right side while

the left plate adjusts the left side. Loosen

the .312-24 x .5 bolt (item 66) located in

the upper front corner of plate. Insert a

screwdriver into the triangle shaped slot

and rotate adjustment plate until neutral is

achieved. Tighten bolt.

7. Repeat procedure on other side of trans-

mission.

8. Reinstall linkage rod in control arm. If rod

end (item 26) does not reinstall into con-

trol arm without moving the control arm,

adjust length of linkage rod until it slides

into control arm to assure neutral adjust-

ment will be maintained when linkage is

connected.

9. Test drive machine for straight line travel

with both levers full forward. If travel is not

in a straight line, adjust the steering lever

stop on the side that is the fastest i.e.: if

machine goes to the left, adjust the right

steering stop to slow down the right trans-

mission until travel is straight ahead.

FUEL SOLENOID ADJUSTMENT

Adjust cable between fuel shut-off solenoid

and engine fuel stop valve to provide full

engagement of the solenoid. The solenoid

should bottom out (be fully engaged) before

fuel stop valve fully engages stop (approx.

.0625" to .125" [1.6 to 3.2 mm] gap).

The solenoid is designed to hold the engine

fuel stop valve open during operation. When

the key is turned on, the solenoid energizes

and opens the fuel valve. When the key is

turned off, the solenoid releases and allows

the fuel stop valve to close.

ADJUSTMENTS AND TROUBLESHOOTING

Fig. 6

Rev. 04-13

37

71

66

Triangle

Shaped Slot

13044

CAUTION

Loading...

Loading...