74

Column 3 “cent.”

The facility to offset the servo travel centre is intended

for adjusting servos whose centre setting is not stan-

dard (servo centre point at 1.5 ms), and also for slight

adjustments, e. g. when adjusting the neutral point of

a model’s control surfaces.

The neutral position can be shifted within the range

-125% to +125% of normal servo travel within the ma-

ximum servo travel of +/-150%, regardless of the trim

lever position and any mixers you have set up. The

centre setting affects the associated servo directly, re-

gardless of all other trim and mixer settings.

Pressing CLEAR resets the value to “0%”.

Column 2 “Rev”

The direction of servo rotation can be adjusted to suit

the actual installation in your model. This means that

you don’t need to concern yourself with servo direc-

tions when installing the mechanical linkages in the

model, as you can reverse them if necessary. The di-

rection of rotation is indicated by the symbols “=>”

and “<=”. Be sure to set the direction of servo rotation

BEFORE you adjust the remaining options!

CLEAR resets the direction of rotation to “=>”

Servo adjustment

Setting servo direction, centre, travel and limit

Servo 1 => 0% 100% 100% 150% 150%

Servo 2 => 0% 100% 100% 150% 150%

Servo 3 => 0% 100% 100% 150% 150%

Servo 4 => 0% 100% 100% 150% 150%

Rev

SEL SYM ASY SYM

ASY

cent. – travel + – limit +

SEL

In this menu you can adjust parameters which only

affect the servo connected to a particular receiver

output, namely the direction of servo rotation, neutral

point, servo travel and (if required) travel limit.

Basic procedure:

1. Hold the rotary control pressed in and select the

appropriate servo (1 to 12).

2. Turn the rotary control to select SEL, SYM or ASY

in the bottom line, prior to making the adjustments

required.

3. Press the rotary control: the corresponding input

fi eld is highlighted (dark background).

4. Set the appropriate value using the rotary control.

5. Finally press the rotary control again to end the in-

put process.

Important:

The numbers in the servo designations refer to the

receiver output socket to which a particular servo is

connected. These numbers do not necessarily coinci-

de with the numbering of the transmitter control func-

tion inputs; indeed any agreement would be pure-

ly accidental. The sophisticated programs of the mx-

24s mean that the numbers are unlikely to be the

same in any case. For example, changing the stick

mode does not affect the numbering (i. e. receiver so-

cket sequence) of the servos.

As a basic rule, always start with the servo setting in

the left-hand column!

Program description: Basic settings

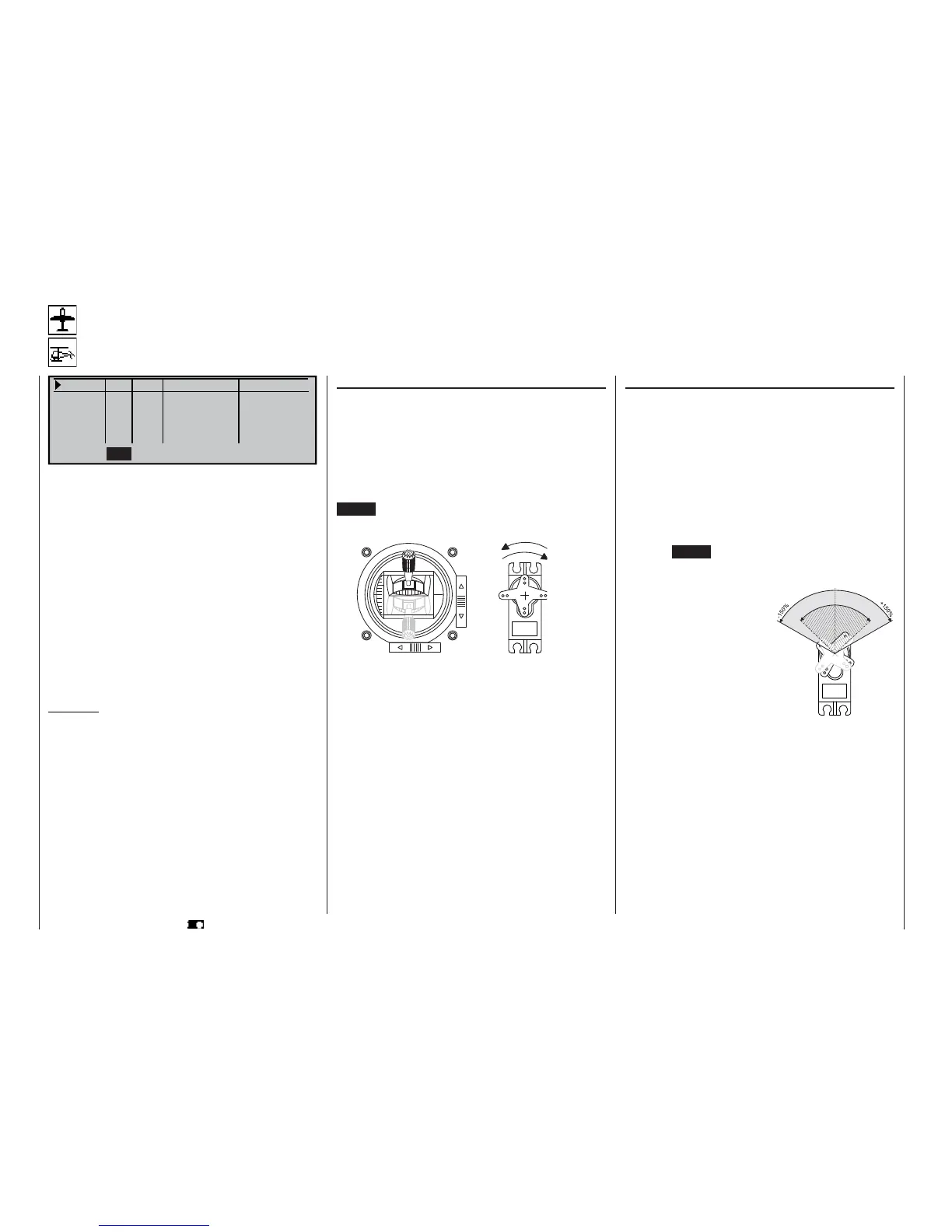

Servo centre offset

S

e

r

v

o

t

r

a

v

e

l

-

1

2

5

%

C

e

n

t

r

e

a

d

j

u

s

t

m

e

n

t

+

1

2

5

%

normal

reversed

reversed

normal

Loading...

Loading...