DC INVERTER MULTI VRF INSTALLATION

148

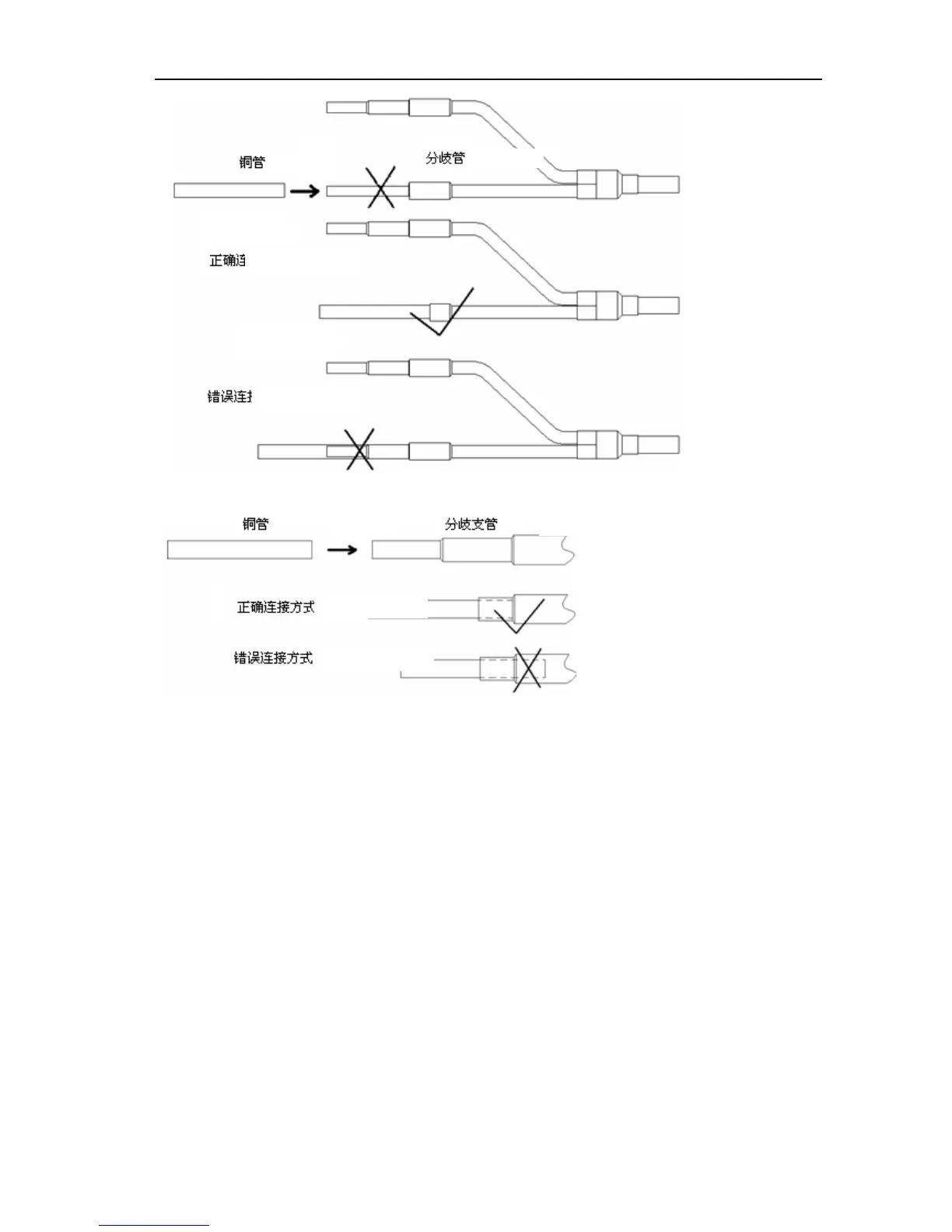

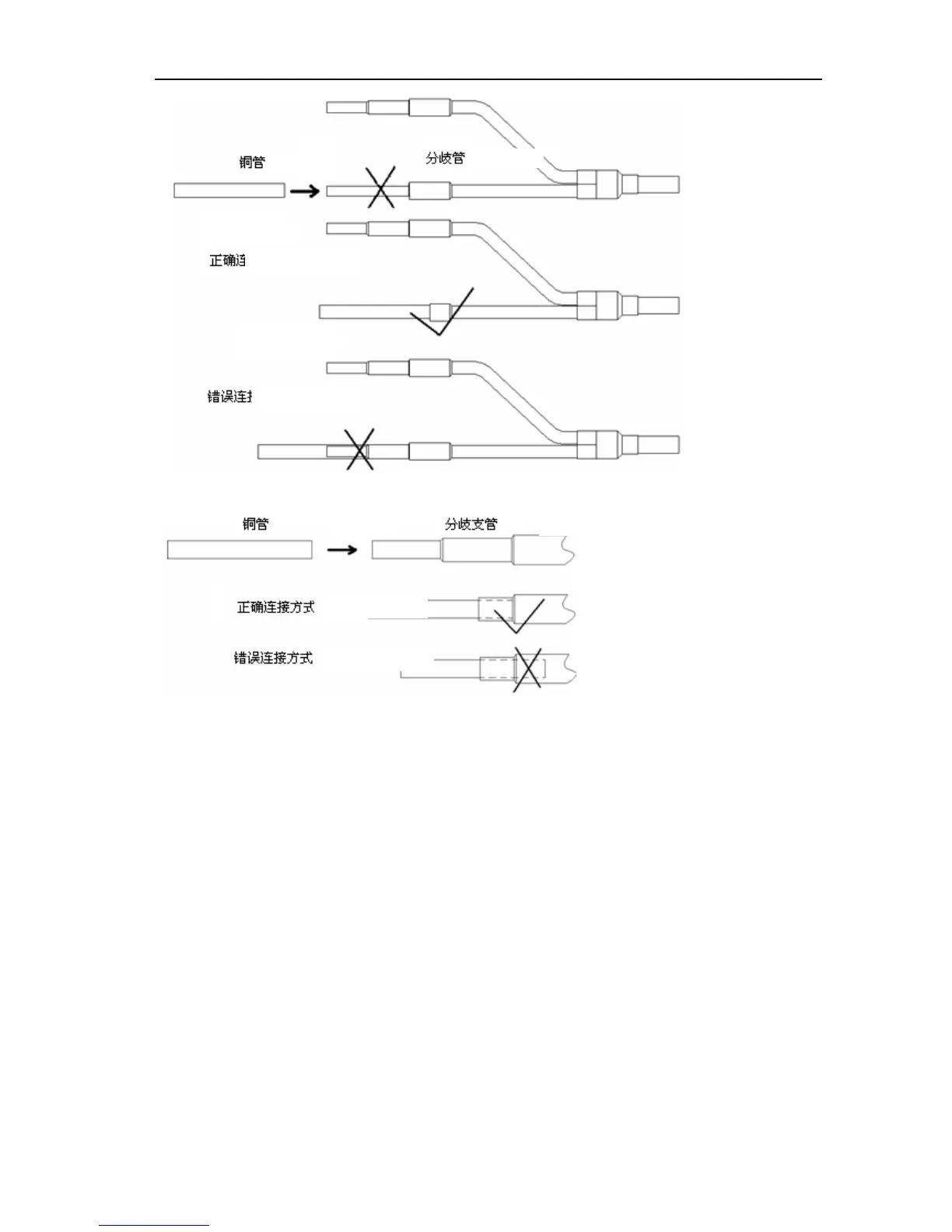

Copper pipe shall not be inserted too much for connection with branch pipe:

6.7 Welding of Copper Pipe

1)Braze welding

Materials for braze welding

There are two kinds of braze welding, soft braze welding and hard braze welding. Hard braze

welding is required in this case.

Selection of braze welding

Red copper + red copper

:brazing filler metal is Bcu93P(GB 6418),and welding flux is not needed.

Flame flux: capable of preventing the surface of copper pipes from oxidation, recommended for

use

Temperature for braze welding

:820-860℃ (copper pipe becomes light red)

2

)Safety acknowledgement before operation

a. Roll calling of construction personnel and confirmation on their health status.

b. Acknowledgement on work suits

(helmets, clothes, safety bags and safety shoes)

c. Description of work location and environment

d. Job division shall be made. Job content, method and order shall be indicated. Risk prediction

activities shall be performed.

e. “Construction Schedule” shall be worked out.

f. Head of each group shall be assigned.

g. Risks of occurrence of an accident such as electric shock or fire shall be indicated.

Branch pipe

Copper pipe

Correct connection

Wrong connection

Copper pipe

Correct connection

Wrong connection

Branch pipe

Loading...

Loading...