DC INVERTER MULTI VRF INSTALLATION

153

◆Cooling

To avoid getting a burn in following processes, common wet cloth (humidity content is low,

meaning that there shall not be water drips when welded part is cooled; and because shrinkage

factor of copper is different from that of welding material, too quick cooling that would cause

cracking of braze welding shall be avoided) can be used for cooling welded parts.

◆The following items shall be checked after welding is completed

● Is there any pore or hole on welded part?

● Is there evident “sagging of brazing filler metal”?

6.8 Cleaning of Refrigerant Piping

After a section of pipeline is welded, cleaning of piping is necessary.

Nitrogen pressure is utilized to remove foreign matters (such as dust, water and beryllium oxide

caused by welding) in the piping.

1

)Main purposes of cleaning are as follows:

To eliminate oxide caused by insufficiency of nitrogen-filled protection during pipe welding.

To remove foreign substances and water that may enter the piping due to improper storage and

transport.

To check whether big leakage is existent at connections of the piping between indoor unit and

outdoor unit

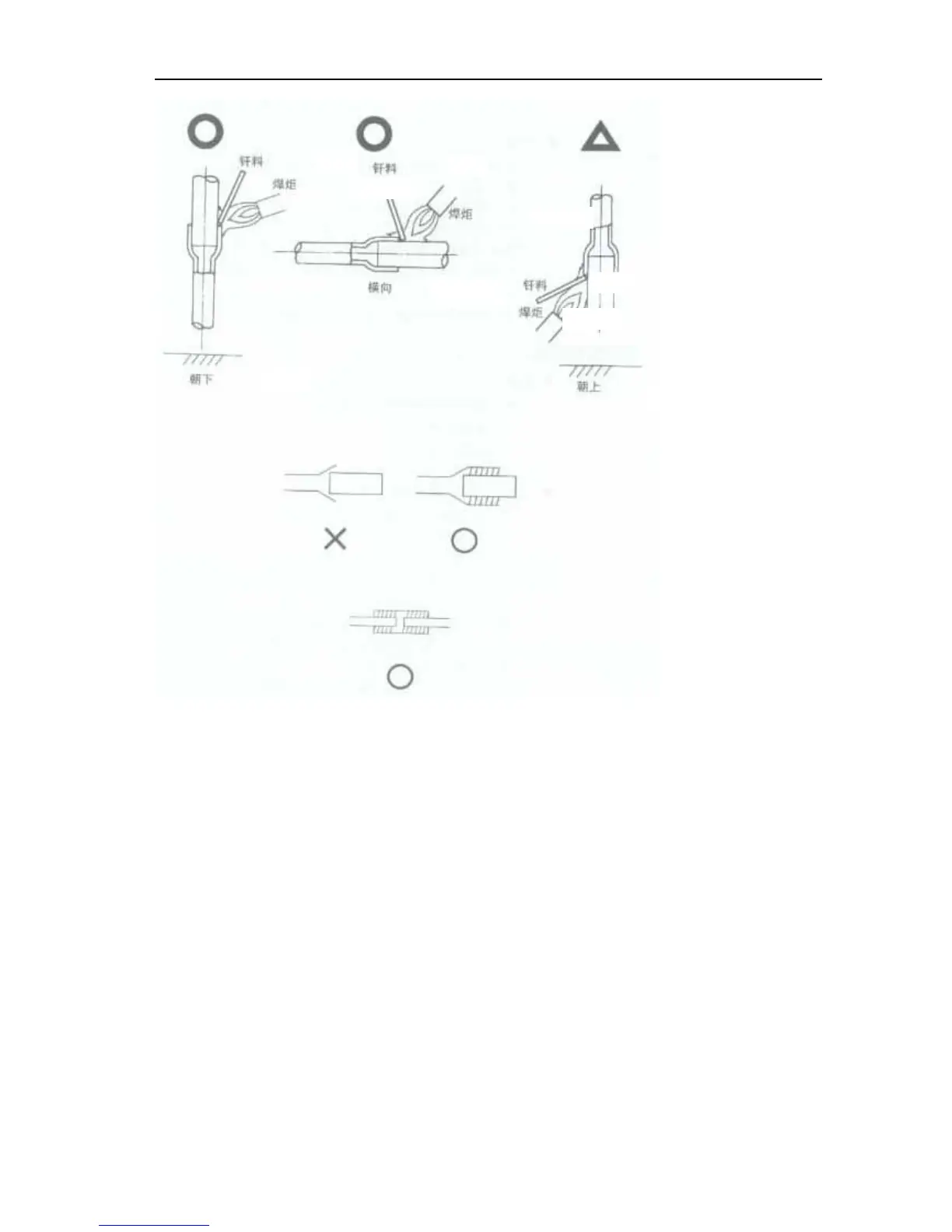

Solder

Weld torch

Transverse

Upward

Downward

Solder

Solder

Weld torch

Weld torch

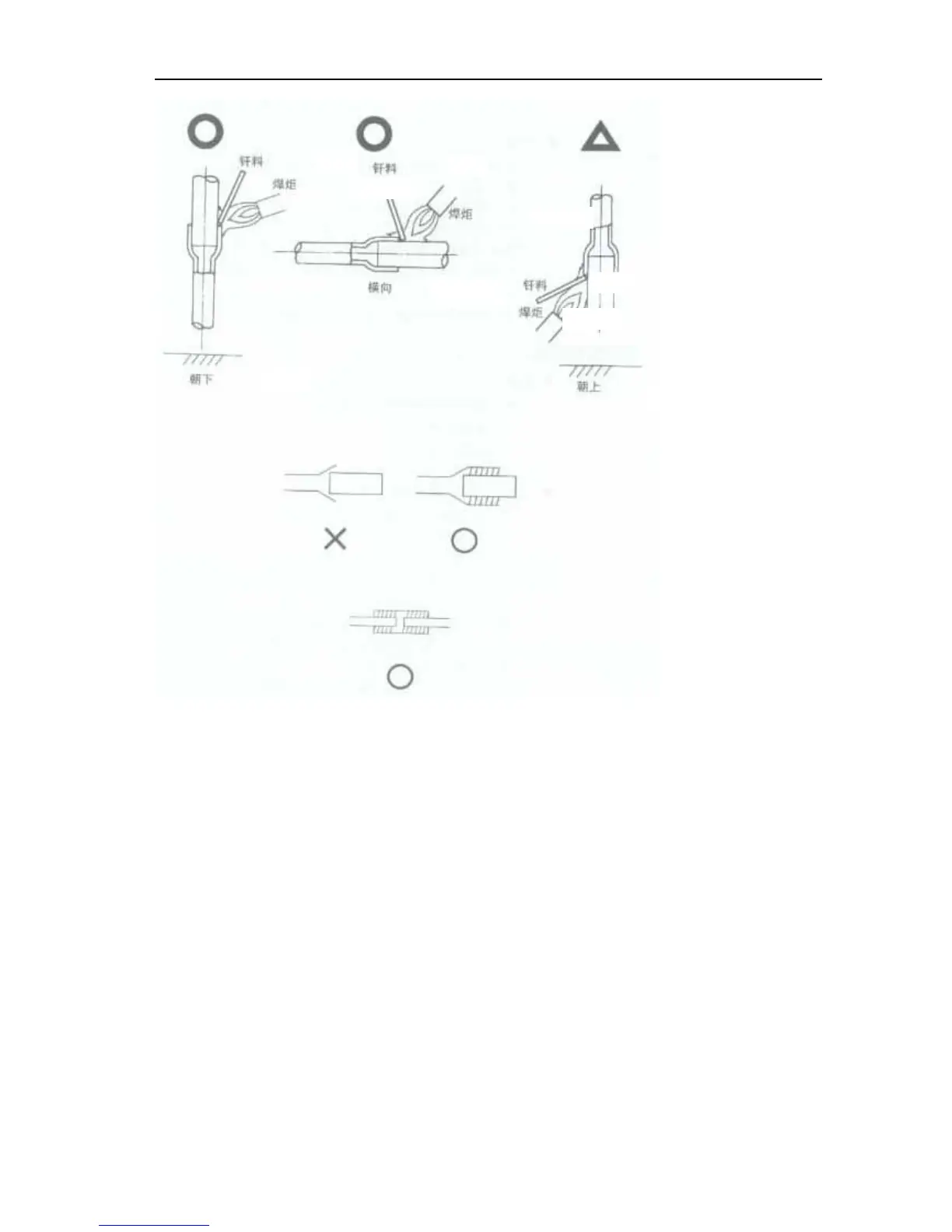

Loading...

Loading...