GREE GMV5E DC INVERTER VRF UNITS SERVICE MANUAL

63

6.3.3 Insulation for Air Ducts

(1) Insulation for air duct components and devices must be performed after the air leakage test is

performed or after quality check.

(2) Use centrifugal glass wool or rubber and plastic materials for insulation or use novel insulation

air ducts.

(3) The insulation layer should be flat and tight without any crack or gap.

(4) Thickness of the Insulation Layer

For the air supply and return air pipe laid in a room without an air conditioner, thickness of the rubber

and plastic insulation layer is 35 mm.

For the air supply and return air pipe laid in an air conditioning room, thickness of the rubber and

plastic insulation layer is 20 mm.

(5) Supports, hangers, and brackets of the air duct must be installed outside the insulation layer. A

chock must be provided between the support, hanger, or brackets and the air duct.

7 Electric and Controller Installation

7.1 Precautions

Both the power cable and communication cable must be connected properly. If the power cable is

connected to the communication port, the main board will be burnt.

The power cable and communication cable can be identified in the following ways:

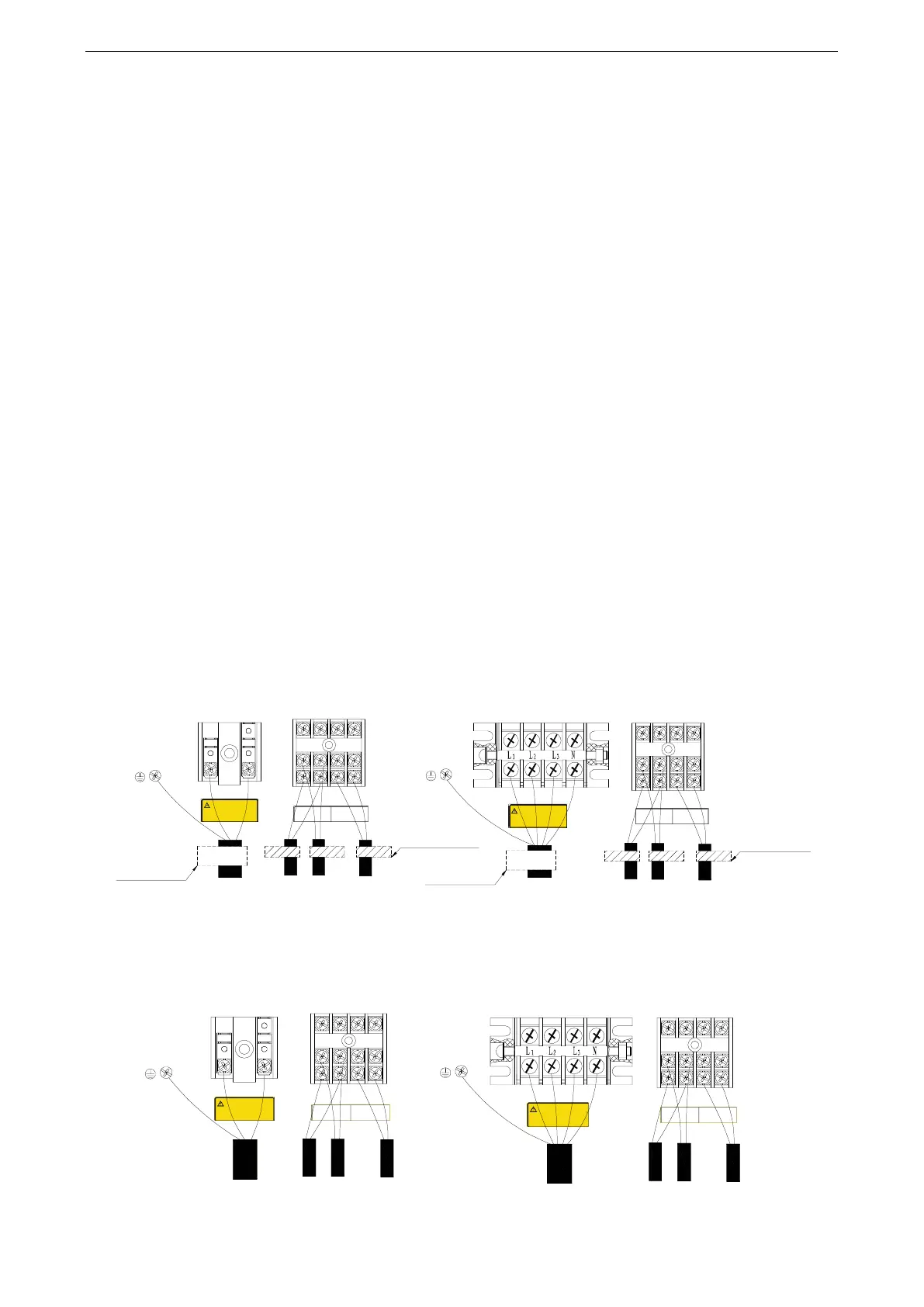

Method 1: Use sheaths in different colours.

L N

L N

D1 D2 H1 H2

D1 D2 H1 H2

Single-phase unit

Grounding

screw

Warning

Warning

1. Reliable grounding is required.

2. The screw for fixing the conducting

wire must be tightened. It must be

replaced if slipped screw head exists.

3. The external conducting wire must

be fixed by a clip. Otherwise, personal

injury or fire may occur.

1. Reliable grounding is required.

2. The screw for fixing the conducting

wire must be tightened. It must be

replaced if slipped screw head exists.

3. The external conducting wire must

be fixed by a clip. Otherwise, personal

injury or fire may occur.

Power cable

Indoor/outdoor unit

communication D1 D2

Wired controller

H1 H2

Indoor/outdoor unit

communication D1 D2

Wired controller

H1 H2

Power cable

Grounding

screw

Indoor/outdoor

communication cable

Communication cable

of the wired controller

Indoor/outdoor

communication cable

Communication cable

of the wired controller

Color label for the

communication cable

Color label for the

communication cable

Color label for

the power cable

Color label for

the power cable

Three-phase unit

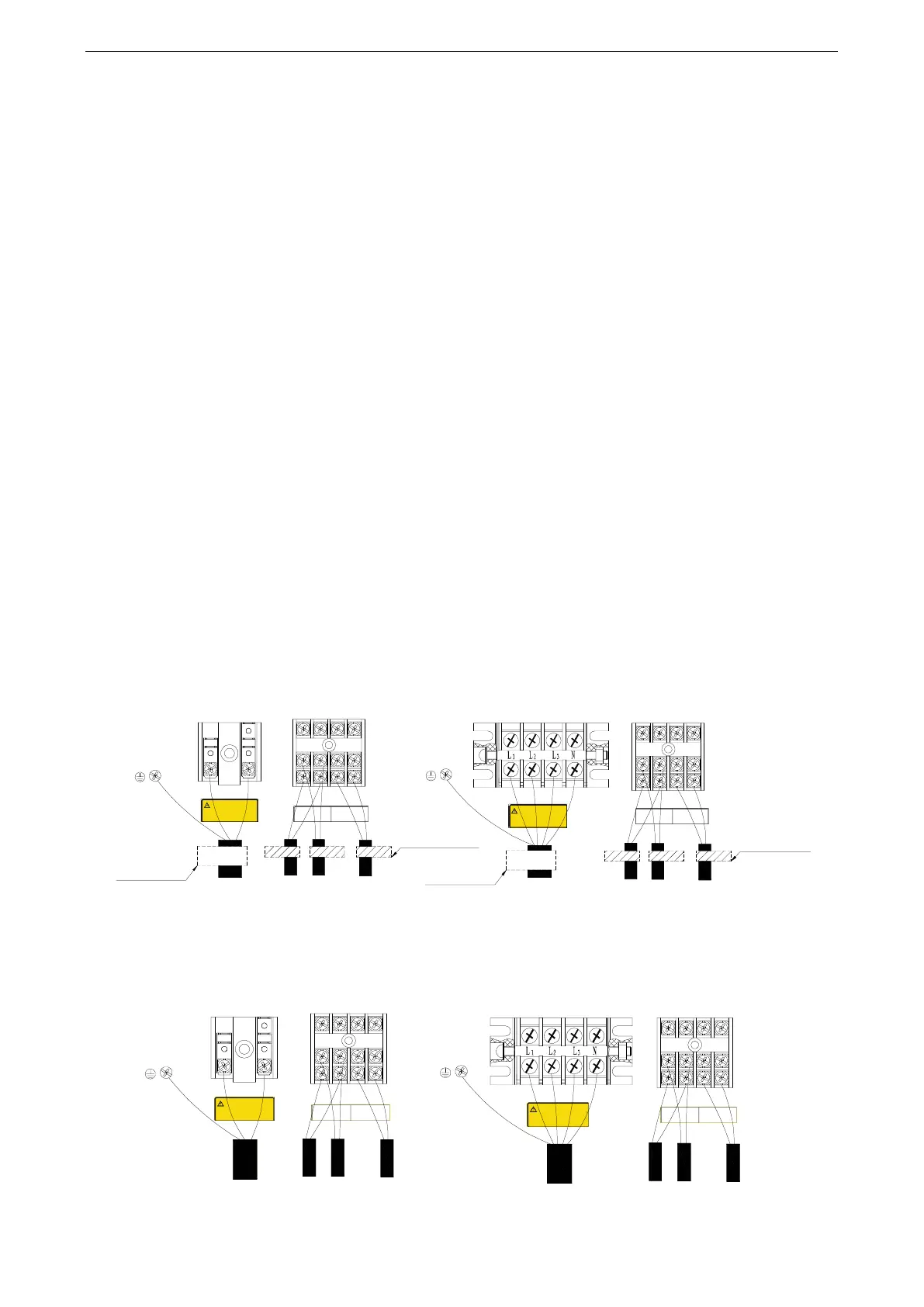

Method 2: Use different types of cables.

The diameter of the power cable is larger than that of the communication cable. Alternatively, adopt

three cores or more for the power cable and two cores for the communication cable.

L N

L N

D1 D2 H1 H2

D1 D2 H1 H2

Single-phase unit

Grounding

screw

Warning

1. Reliable grounding is required.

2. The screw for fixing the conducting wire

must be tightened. It must be replaced if

slipped screw head exists.

3. The external conducting wire must be

fixed by a clip. Otherwise, personal injury

or fire may occur.

Power cable (three-core)

(The yellow green cable

is the ground cable.)

Indoor/outdoor unit

communication D1 D2

Wired controller

H1 H2

Indoor/outdoor

communication

cable (two-core)

Communication

cable of the wired

controller (two-core)

Three-phase unit

Grounding

screw

Power cable (five-core)

(The yellow green cable

is the ground cable.)

Indoor/outdoor

communication

cable (two-core)

Communication

cable of the wired

controller (two-core)

Indoor/outdoor unit

communication D1 D2

Wired controller

H1 H2

Warning

1. Reliable grounding is required.

2. The screw for fixing the conducting wire

must be tightened. It must be replaced if

slipped screw head exists.

3. The external conducting wire must be

fixed by a clip. Otherwise, personal injury

or fire may occur.

Loading...

Loading...