GREE GMV5E DC INVERTER VRF UNITS SERVICE MANUAL

70

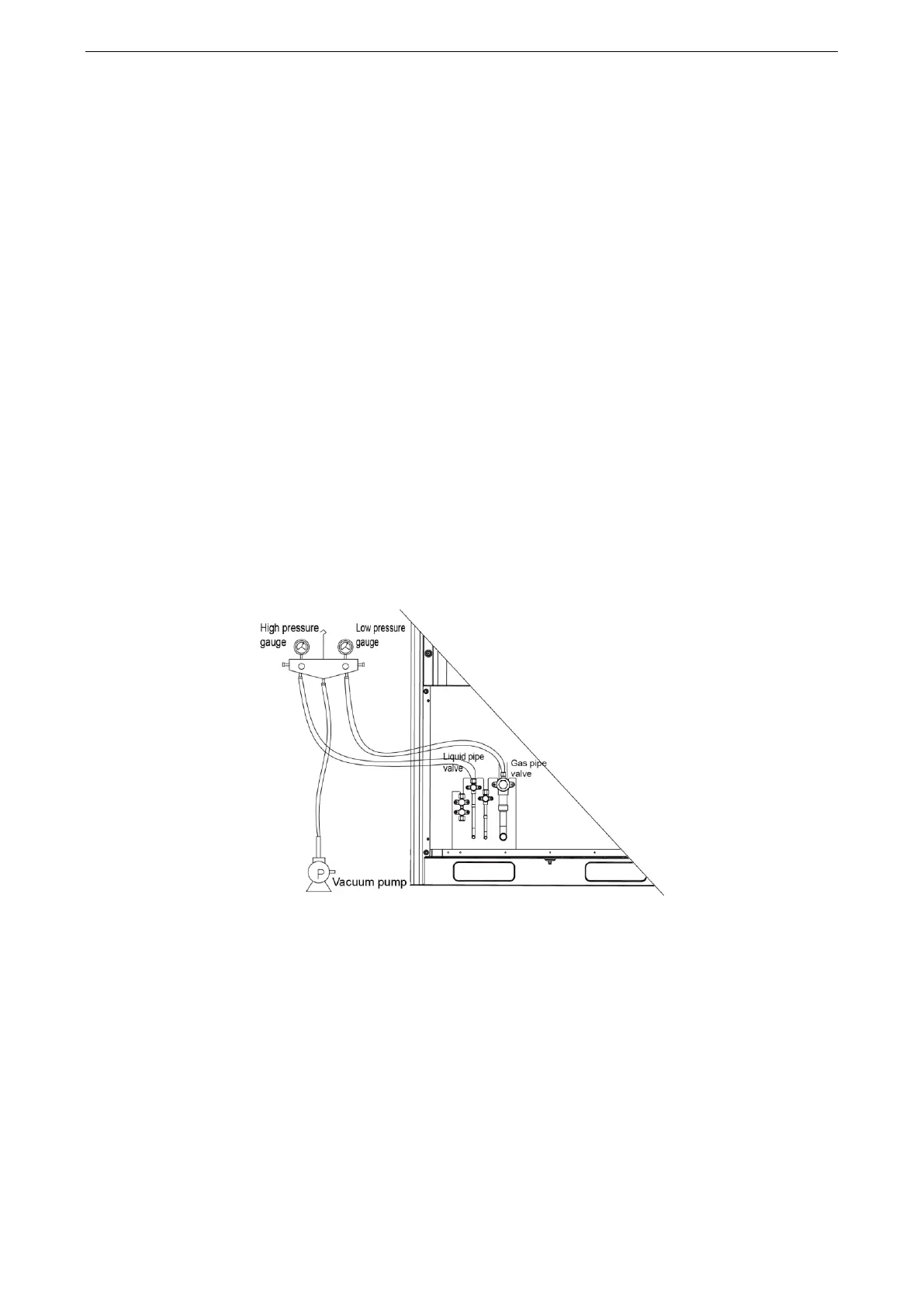

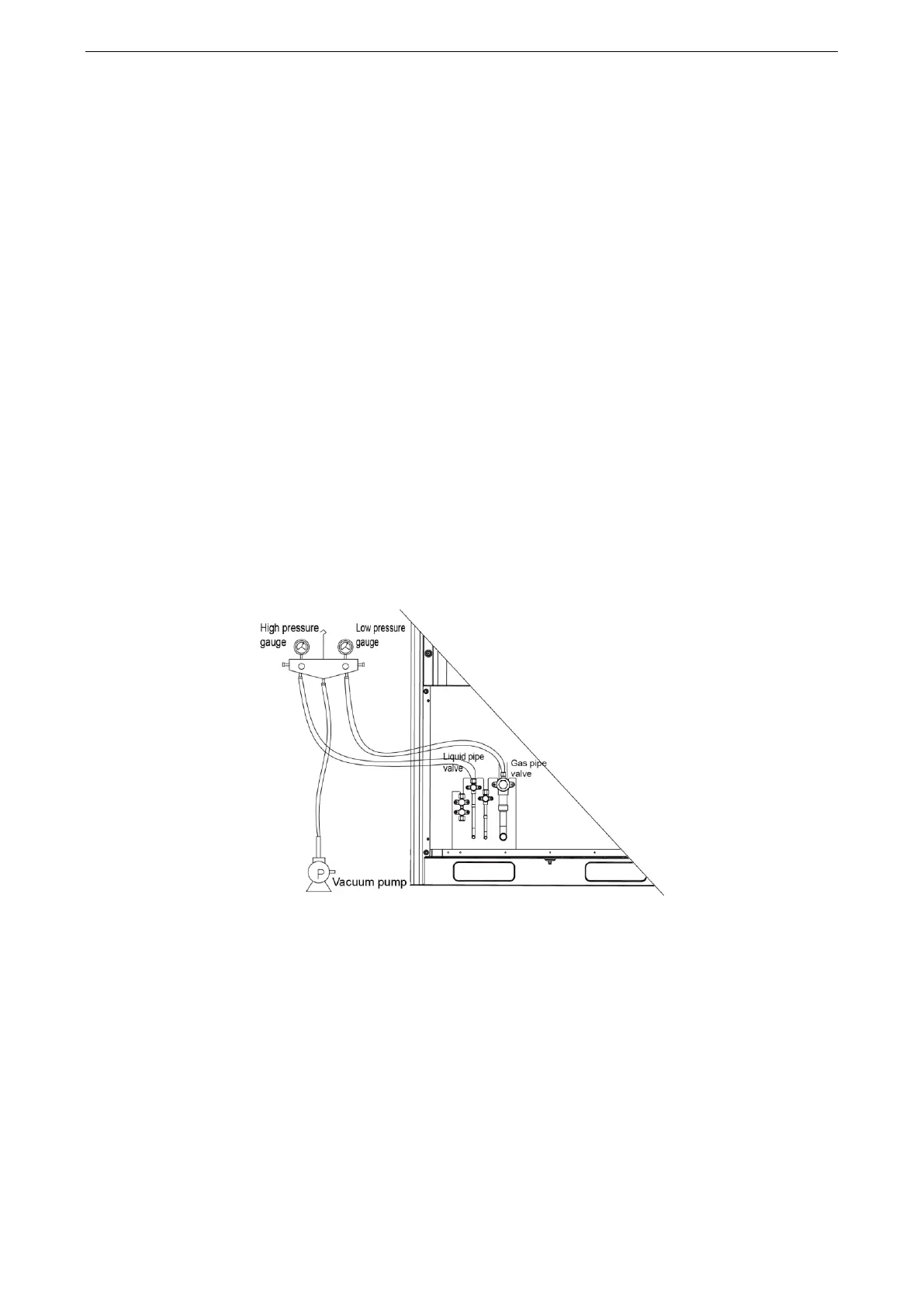

The system vacuum pump must be equipped with a check valve.

8.2.2 Procedure and Precautions for Vacuumization and Desiccation

8.2.2.1 Procedure

a) Before vacuumization, ensure that the stop valves of the gas and liquid pipes are turned off.

b) Use the perfusing duct to connect the regulator valve and vacuum pump to detection connectors

of the gas pipe and liquid pipe.

c) Vacuumize for 4 hours and check whether the vacuum degree reaches -0.1 MPa or more. If not,

leakage may exist. Perform leakage check again. If no leakage exists, continue to vacuumize for

2 hours.

d) If the vacuum degree cannot be kept after vacuumization is performed for twice, there may be

water in the pipe when it is confirmed that no leakage exists. In this case, discharge water by

means of vacuum breaking. Perfuse nitrogen at 0.05 MPa to the pipe. Vacuumize for 2 hours and

keep vacuuming for 1 hour. If the vacuum degree of -0.1 MPa cannot be reached, repeat this

operation till water is discharged.

e) After vacuumization, turn off the regulator valve and keep for 1 hour. Ensure that the pressure of

the regulator valve does not increase.

8.2.2.2 Precautions:

a) The gas pipe and liquid pipe must be vacuumized at the same time.

b) Turn off the valve before powering off the vacuum pump.

c) Keep vacuuming for 2 hours. The vacuum meets the requirement if the pressure displayed by the

vacuum gauge does not increase.

d) The units parallel connected to the module and oil-equalizing pipe also need to be vacuumized.

9 Refrigerant Perfusion

9.1 Calculation Method for Perfusing Refrigerant

Quantity of refrigerant perfused for the pipe (R) = Quantity of refrigerant perfused for the pipe (A) +

∑ Quantity of refrigerant perfused for each module (B)

Loading...

Loading...