GREE GMV5E DC INVERTER VRF UNITS SERVICE MANUAL

69

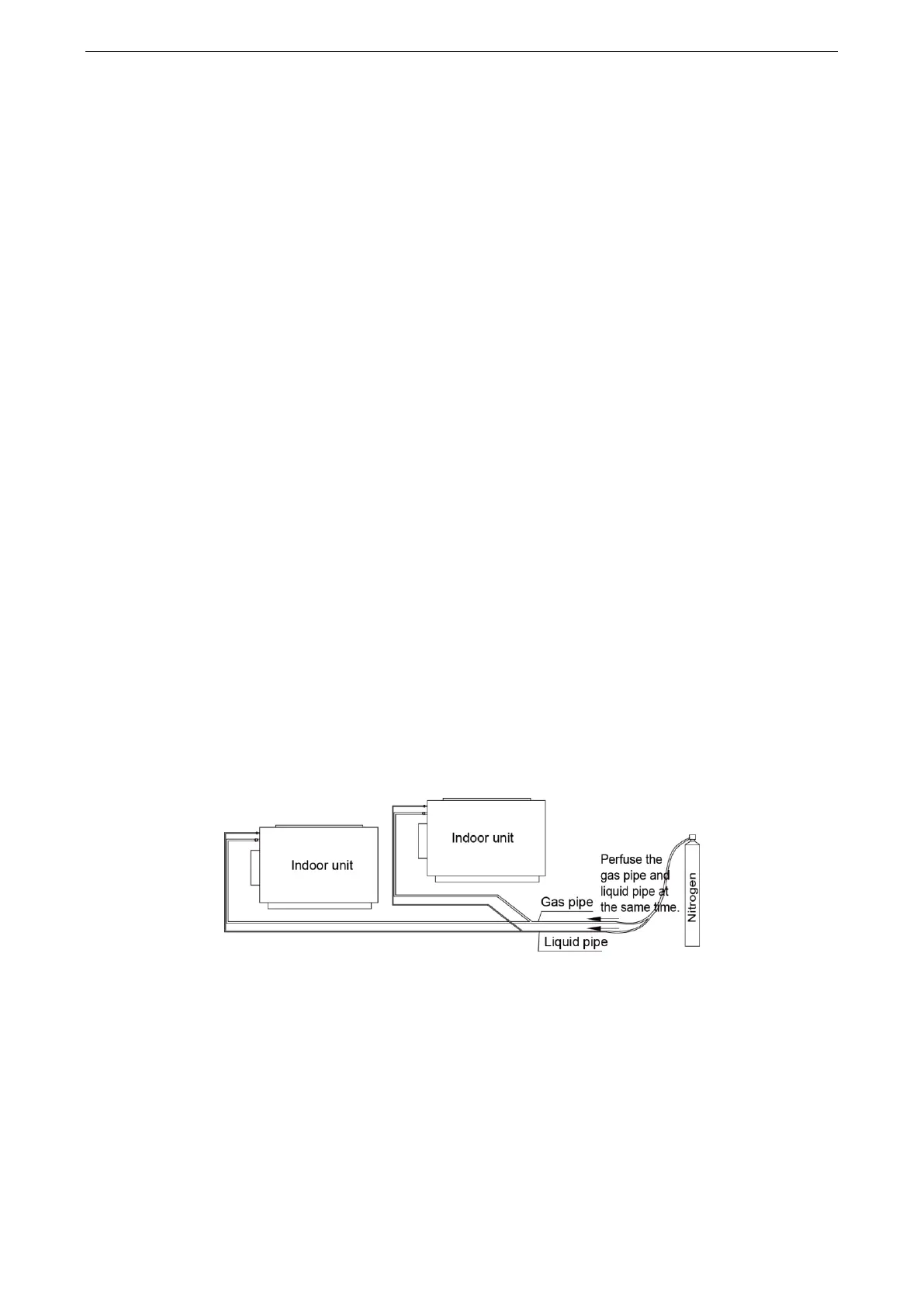

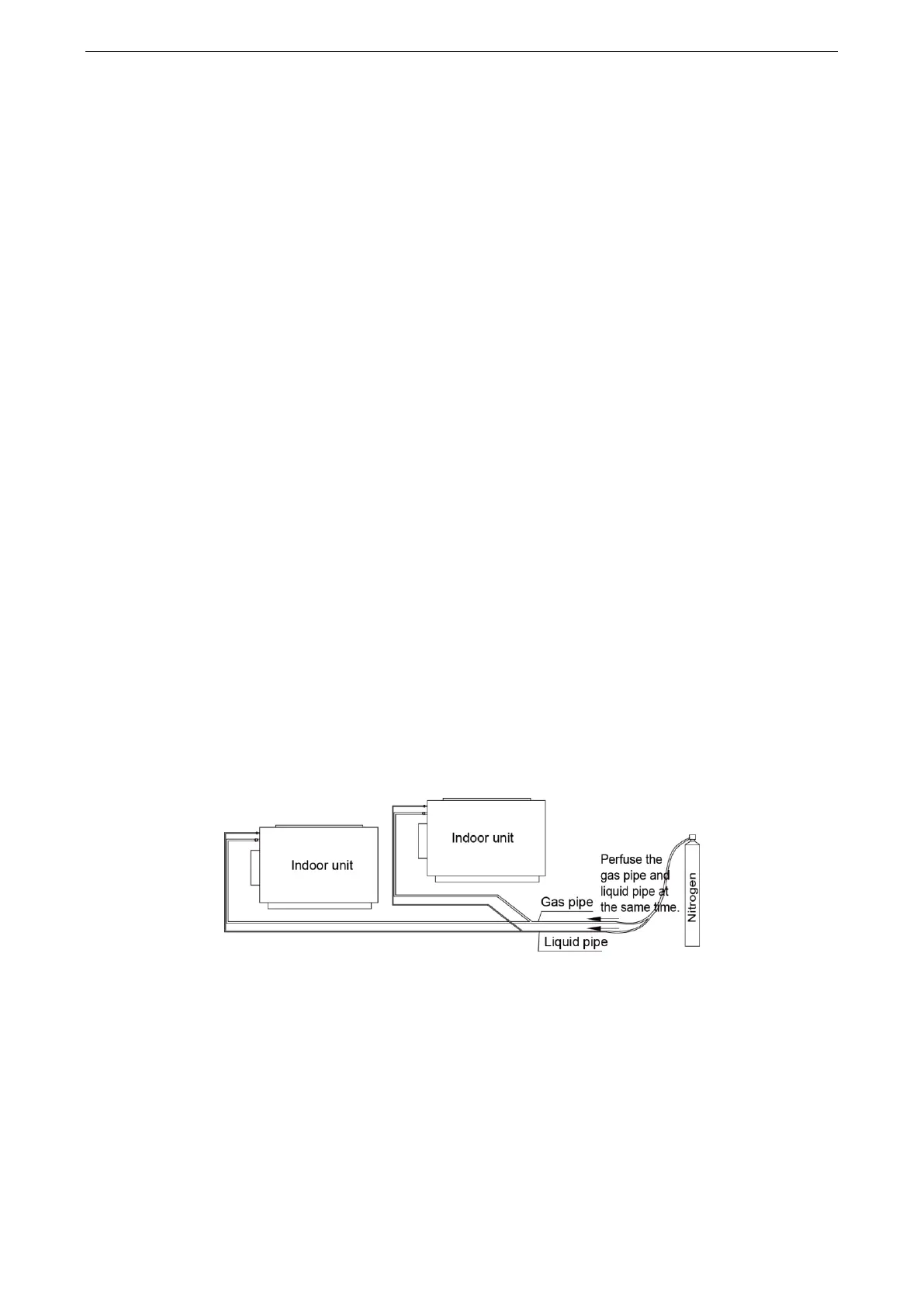

8.1.2 Procedure for Performing the Air-tightness Test

Stop valves of the gas and liquid pipes of the ODU are turned off at delivery.

Before test, apply a small amount of required lubricant on the block nut and pipe terminals and use

two wrenches to fix the block nut.

The ODU pipes cannot be connected when the air-tightness test is being performed.

The test pressure for R410A system is 4.0 MPa. Use dry nitrogen as media for the air-tightness test.

Increase the pressure slowly by following the steps below:

Step 1: Increase the pressure to 0.5 MPa. Stop for 5 minutes and then perform air-tightness check.

Major leakage may be detected.

Step 2: Increase the pressure to 1.5 MPa. Stop for 5 minutes and then perform air-tightness check.

Minor leakage may be detected.

Step 3: Increase the pressure for R410A system to 4.15 MPa. Stop for 5 minutes and then perform

strength check. Slight leakage or blow holes may be detected. After increasing the pressure to the test

pressure, keep the pressure for 24 hours and check whether it decreases. If the pressure does not

decrease, it meets the requirement.

8.1.3 Precautions:

a) The measuring range of the test pressure gauge for R410A system must be above 4.5 MPa.

b) Record the value displayed on the pressure gauge, ambient temperature, and test time.

c) Pressure correction: The pressure changes by 0.01 MPa when the temperature changes by 1°C.

d) The pressure meets the requirement if it does not change.

e) If the pressure must be kept for a long time, decrease the pressure to 0.5 MPa or lower. High

pressure for a long time may cause leakage at the welding point or safety hazard.

f) Before performing the air-tightness test to the refrigerant pipes, do not conduct insulation or

wrapping at the welding or flaring opening joints of the IDU. The pressure must be increased

simultaneously for pipes on outdoor sides and cannot be increased for pipes on one side.

Note:

Before performing the air-tightness test, do not conduct insulation or wrapping at the welding

joints.

8.2 Vacuumization and Desiccation for the System

8.2.1 Requirements on the Vacuum Pump

The vacuum pump for different refrigerant systems cannot be the same.

The ultimate vacuum degree of the vacuum pump should reach -0.1 MPa.

The air discharge capacity of the vacuum pump must be greater than 4 L/S.

The precision of the vacuum pump must be greater than 0.02 mmHg.

Loading...

Loading...