910FS Splicer

Greenlee / A Textron Company 4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

43

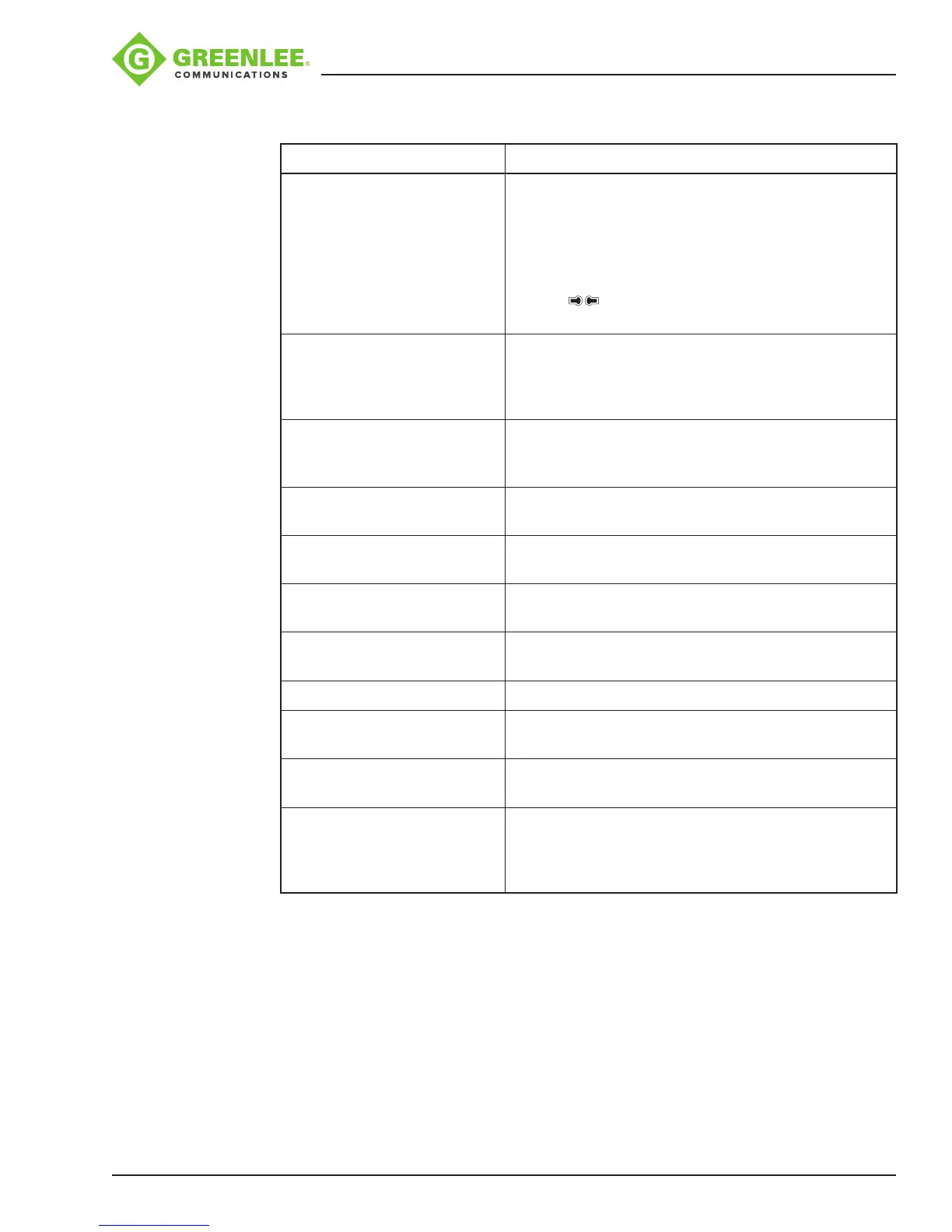

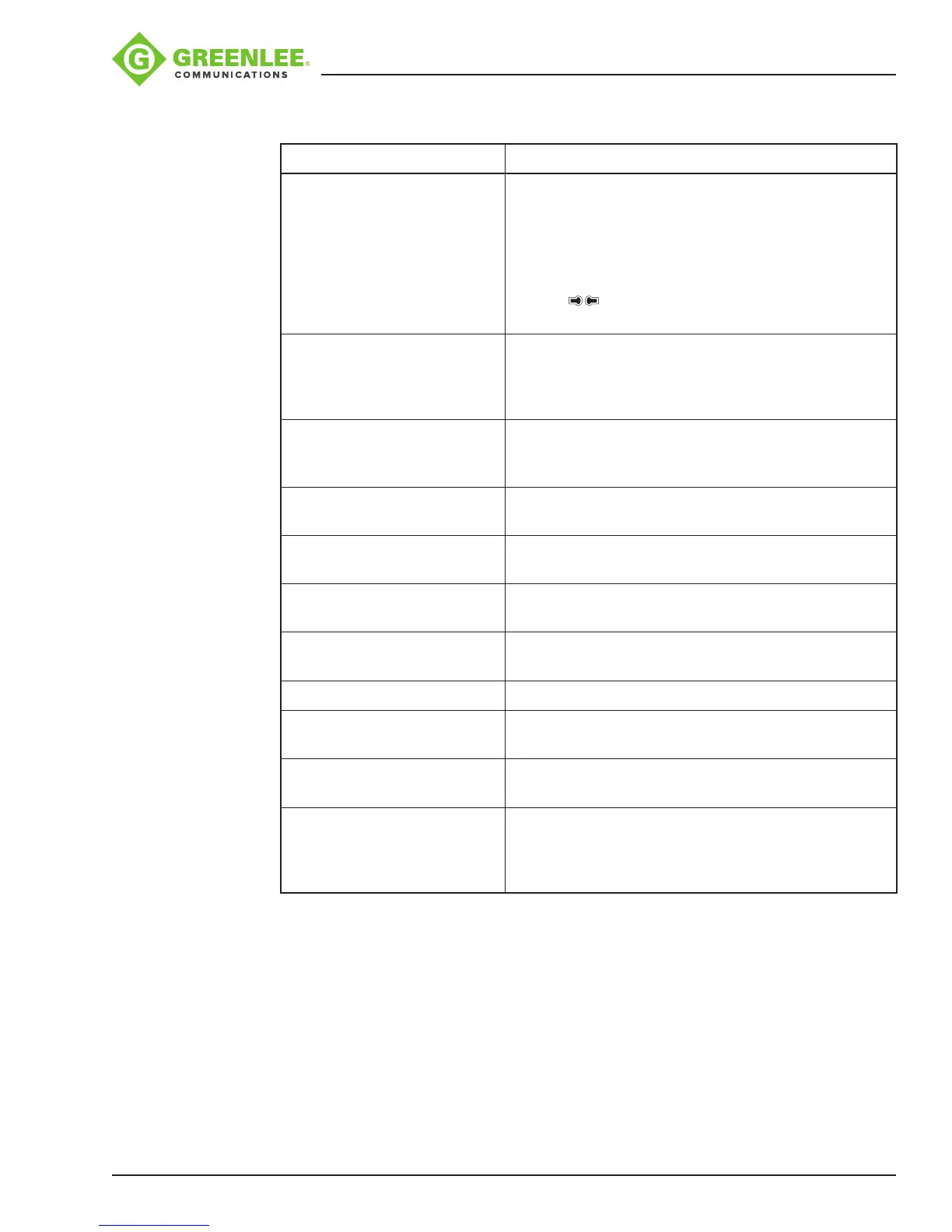

If High Estimated Loss

Reason Solution

Insufcient ber cleaning. Dust or dirt on the ber surface results in bad splice

loss and low tensile strength.

• Clean the ber surface sufciently.

• Do not clean the ber after cleaving to prevent dust

on the ber end-face.

• Avoid any contact with the ber end-face.

• Press to perform an arc calibration as dened

in this instruction manual.

Bad ber end-face. • Check the condition of ber cleaver. If the blade is

worn, rotate the blade to a new position.

• Conrm the “Cleave Limit” setting; 2.0° or less is

recommended.

Dust or dirt is on the V-groove

or the clamp chip.

Dust or dirt on the V-groove or clamp chip causes

poor ber movement during ber adjusting. Clean

them periodically.

Dust or dirt is on the lens or

mirror.

If dust or dirt exists, clean the lenses or mirrors.

Bad electrode condition. Replace the electrodes if they appear worn (rounded

tip shape), dirty, or bent.

Inadequate arc power. Calibrate the arc power with the “Arc Calibration”

function.

Using unsuitable splice mode. Select a suitable splice mode for the bers to be

spliced.

“Loss Limit” is set too low. Increase “Loss Limit” to an adequate limit.

Fibers were spliced after Error

was canceled.

Select the appropriate splice mode from the Other

modes.

Inadequate arc parameters in

other splice modes.

Conrm the arc parameters are adequate to splice the

bers.

Inadequate estimating

parameters in Other mode.

Conrm the estimating parameters are adequate to

estimate the loss. The MFD mismatch function does

not work for certain types of specialty bers. In these

cases, set the “MFD Mismatch” to OFF.

Loading...

Loading...