GRISWOLD PUMP COMPANY Installation Page 9

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Installation Page 11

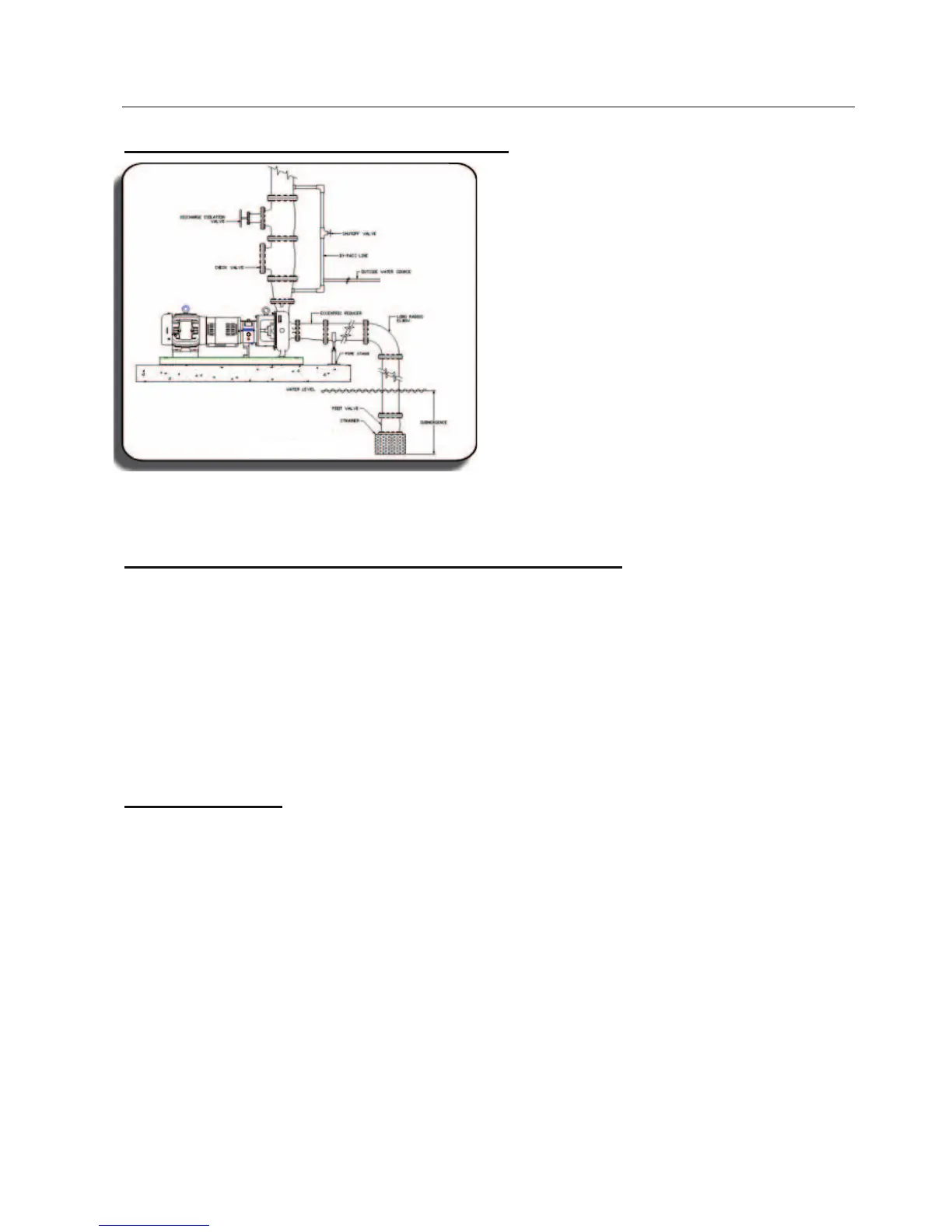

Suction Piping – Suction Lift Installations

1. Suction lines when operating under lift

conditions must be absolutely free from

air leaks.

2. Suction piping should gradually slope

upward toward the pump.

3. NPSH available must be greater than the

NPSH required by the pump.

4. A means of priming the pump, such as a

foot valve, must be provided.

5. Pipe must be supported properly to

prevent flange loading.

6. Provide adequate submergence over the

suction pipe inlet to prevent formation

of vortices.

Suction Piping – with Positive Head (Flooded Suction)

1. The suction line must include an isolation valve to close off the source of supply when

performing inspection or maintenance on the pump. Install this valve at least two pipe

diameters before the pump suction nozzle.

2. Piping should be level or gradually slope downward from the suction source in order to

avoid air pockets.

3. Attention should be paid to the design of the exit from the supply source to prevent the

formation of vortices or eddies that can draw air into the pump. This relates to the

velocity of the outflow and the submergence of the supply exit below the liquid level.

Discharge Piping

1. Discharge piping will normally be larger than the pump discharge size, so a concentric

increaser is usually used for adaptation. Locate increaser below check valve.

2. A check valve and isolation valve should be located in the discharge line. The check

valve should be located between the isolation valve and the pump. This will prevent back

flow through the pump (reverse rotation) and will also serve to reduce any back pressure.

3. If an expansion joint is used, it should be located between the check valve and the pump.

Proper anchoring is necessary.

FIGURE 5

Loading...

Loading...