GRISWOLD PUMP COMPANY Pump Operation Page 20

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Pump Operation Page 22

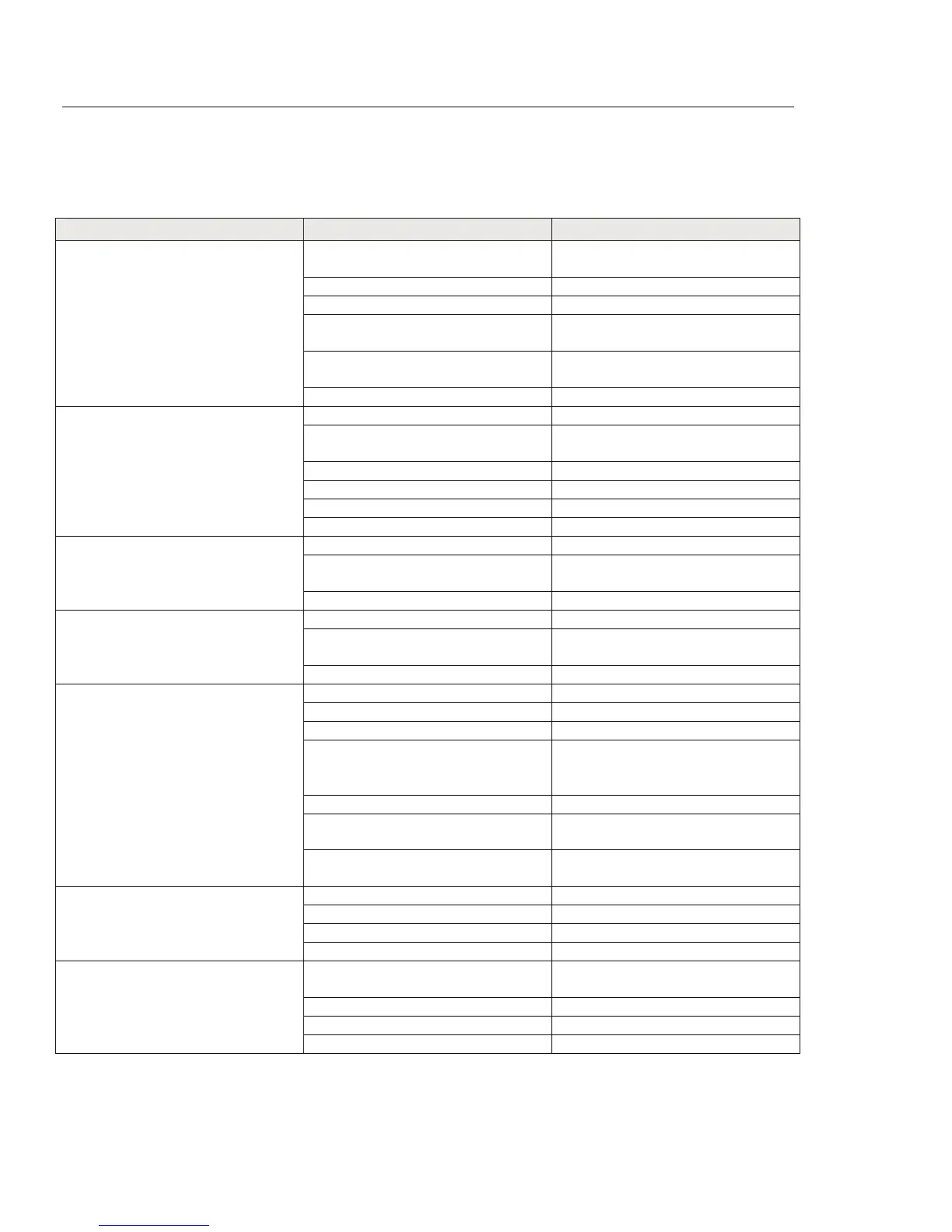

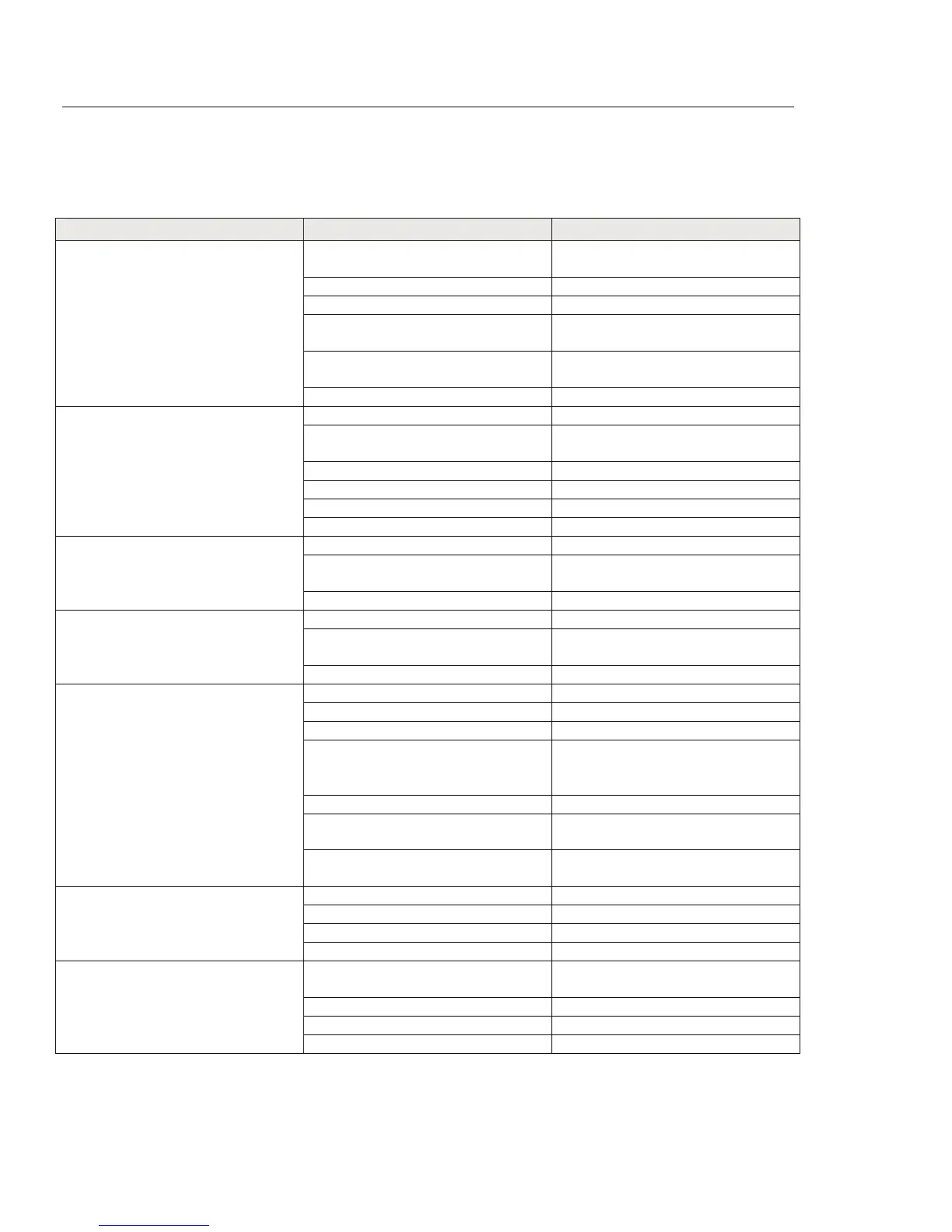

Troubleshooting

If problems are encountered during start-up or pump operation, refer to the folowing table for

likely causes:

Problem Likely Cause Remedy

Pump not primed Re-prime pump, check that suction

line is full of liquid

Suction line obstructed Remove obstruction

Impeller clogged Remove obstruction

Wrong direction of rotation

Note - Possible severe damage!

Check rotation, change if necessary

Foot valve or suction pipe has

inadequate submergence

Check suction source for vortexing,

correct as necessary

No liquid delivered

Suction lift too high Review/revise level on suction

Air leak through gasket Replace gasket, tighten connections

Air leak through stuffing box

Inspect packing/mechanical seal,

add pressurized flush if necessary

Impeller partially clogged Remove obstruction

Excessive impeller clearance Adjust impeller clearance

Inadequate suction head Review/revise design

Pump does not produce rated flow or

head

Worn or damaged impeller Inspect/replace as necessary

Pump improperly primed Re-prime pump

Air or vapor in suction line

Review/revise suction piping to

eliminate air pockets

Pump starts then stops pumping

Air leak in suction line Check gaskets, repair leak

Improper alignment Re-align pump and driver

Improper lubrication

Check lubricant for applicability and

level/quantity

Bearings run hot

Bearing cooling not working Check cooling water line(s)

Improper alignment Re-align pump and driver

Partial impeller clog/imbalance Remove obstruction

Broken or bent impeller or shaft Replace as necessary

Foundation not rigid

Tighten hold-down bolts of base,

pump and motor. Recheck

alignment.

Worn bearings Replace as necessary

Suction and/or discharge piping not

anchored correctly

Review design, modify as necessary

Pump is noisy or vibrates

Pump cavitation

Review suction system, correct

problem(s)

Packing gland improperly adjusted Tighten gland nuts

Stuffing box not packed properly Check, re-pack as necessary

Shaft sleeve scored, ridged Replace as necessary

Excessive stuffing box leakage

Worn mechanical seal Replace as necessary

Actual head lower than design

Throttle discharge valve slightly,

trim impeller. Review design

Liquid heavier than expected Review design

Stuffing box packing too tight Re-pack pump

Excessive power required

Rotating parts binding Check pump internals

Loading...

Loading...