GRISWOLD PUMP COMPANY Routine and Preventive Maintenance Page 35

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Routine and Preventive Maintenance Page 37

Never mix greases of different consistencies or different types.

Maintenance and monitoring intervals should be shortened if the pump is applied in especially

severe service such as highly corrosive liquids or applications with measurable amounts of

solids.

Lubrication Topics

All bearings will fail eventually, and the cause is usually a failure of the lubricating medium, not

fatigue. Particular attention needs to be paid to this in order to maximize bearing life. The

standard lubrication for the Model 811 is flood oil. Provisions are made on the pump for use of

regreasable bearings and also for application of oil mist systems.

Listings of suitable oils and greases are shown in the Appendix II, page 42.

With flood oil lubrication, the proper level is at the mid-point of the bull’s-eye sight glass on the

side of the bearing frame. Avoid over-lubrication. It can be just as bad as under-lubrication.

Excess oil will cause a slightly higher HP draw and will generate heat. Any extra heat is not a

good thing. It can also cause frothing of the oil. After the initial start-up of the pump, or after a

bearing change-out, the oil should be changed after 200 hours of operation and every 2000 hours

(or three months) thereafter. If any cloudiness is observed in the oil, it’s indicative of water

greater than 2000 PPM concentration. The oil needs to be changed immediately. The most

common cause of water contamination is condensation.

If the pump is furnished with regreasable bearings, note that the shields must be located toward

the interior of the bearing frame. Bearings should be regreased every 2000 hours of operation or

three months, whichever comes first. When regreasing, be sure that the grease fittings are

absolutely clean. Any contamination will decrease bearing life dramatically. Avoid

overgreasing as this can cause localized high temperatures in the bearing races and create caked

solids which are not good. After regreasing, bearings may run at a slightly higher temperature

for a period of one to four hours. Remove grease plugs (408H) from the bottom of the frame.

Pump grease through the fittings into each bearing cavity until fresh grease comes out of the

relief ports.

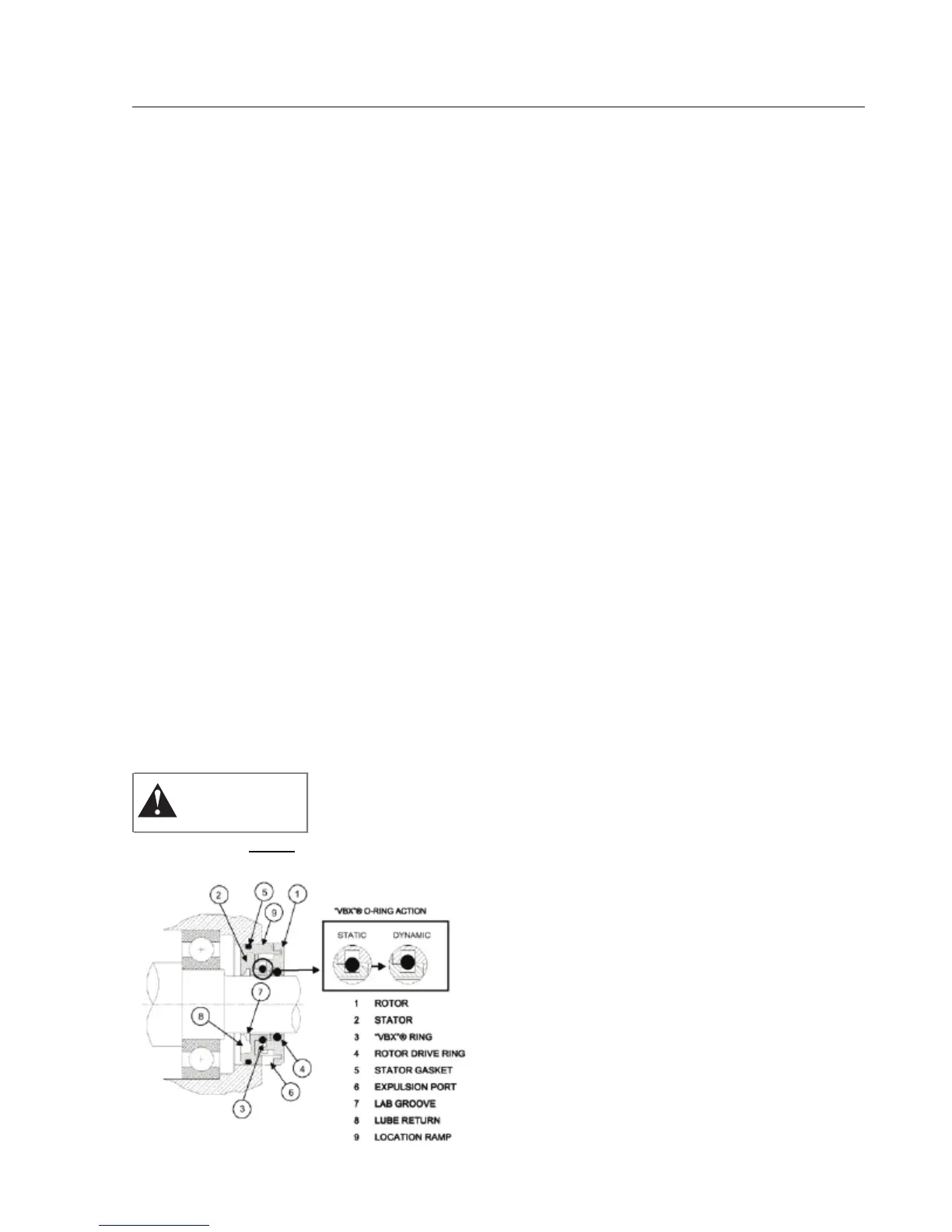

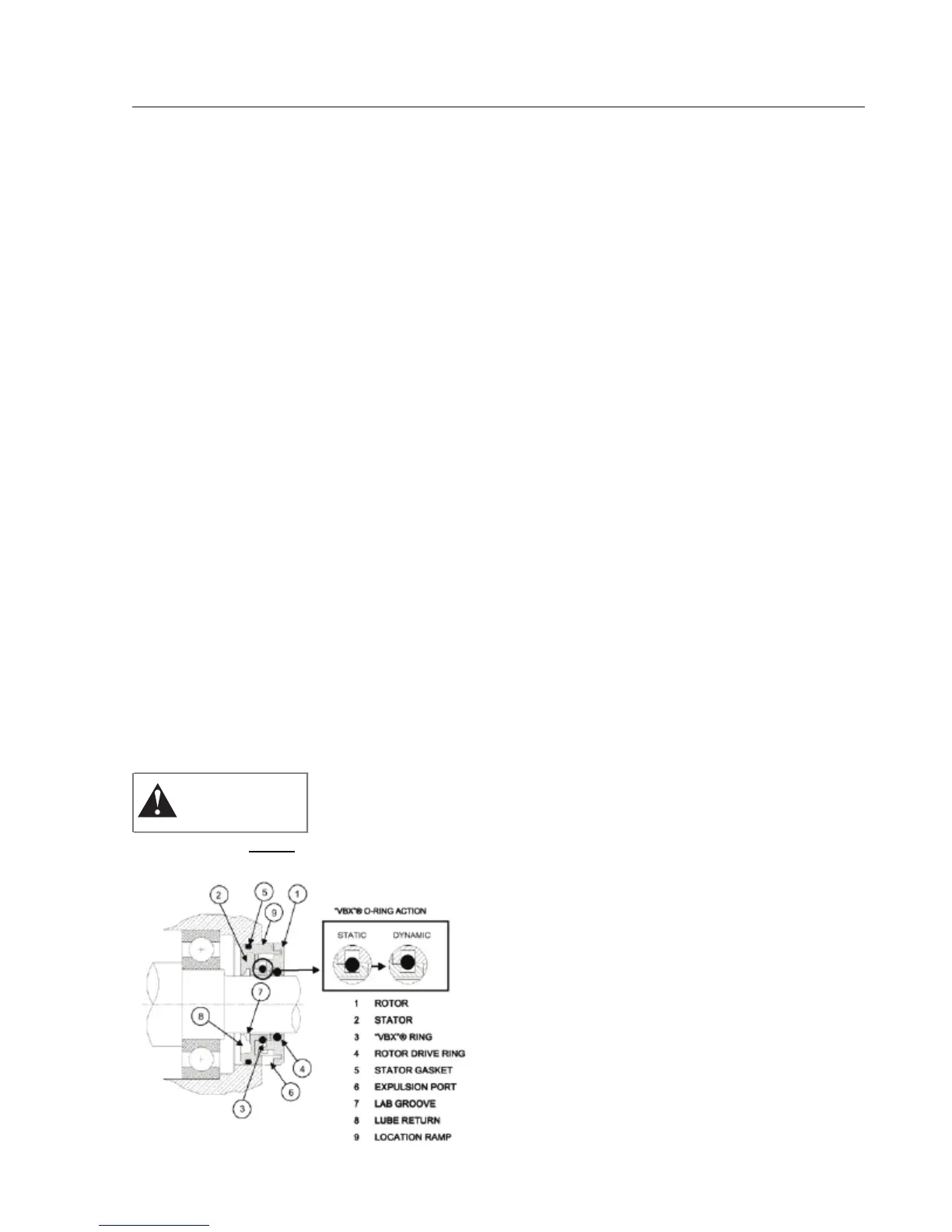

Bearing Isolators

The Model 811 pump is furnished with Inpro®

bearing isolators. These labyrinth seals are very

effective at keeping oil in the bearing frame and

keeping contaminants out. For proper operation,

the drain hole needs to be at the bottom (six

o’clock position). This is a non-contacting seal

and, therefore, has a theoretically infinite life.

Due to its close clearances, however, it can be

damaged through an outright bearing failure. Its

rotor is driven by a replaceable o-ring, which fits

CAUTION

Loading...

Loading...