GRISWOLD PUMP COMPANY Appendix Page 38

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company

Appendix Page 40

Drive power must be locked out to prevent accidental start-up and physical injury.

Drive power must be locked out to prevent accidental start-up and physical injury.

Impeller Clearance Adjustment

Feeler Gauge Method

1. Lock out power supply to motor.

2. Remove coupling guard and coupling

spacer.

3. Loosen jack bolts (370D) and jam nuts

(423).

4. Tighten bearing housing bolts (370C)

evenly, while slowly rotating the shaft until

the impeller just starts to rub on the casing.

5. Using a feeler gauge set the gap between the

three housing bolts (370C) and the bearing

housing. Set the gap according to the table,

below, as required.

6. Tighten jacking bolts (370D) evenly, until

bearing housing backs out and contacts the bearing housing bolts (370C).

7. Tighten jam nuts (423) evenly. Rotate shaft to make sure that it turns freely.

8. Reinstall coupling spacer and coupling guard.

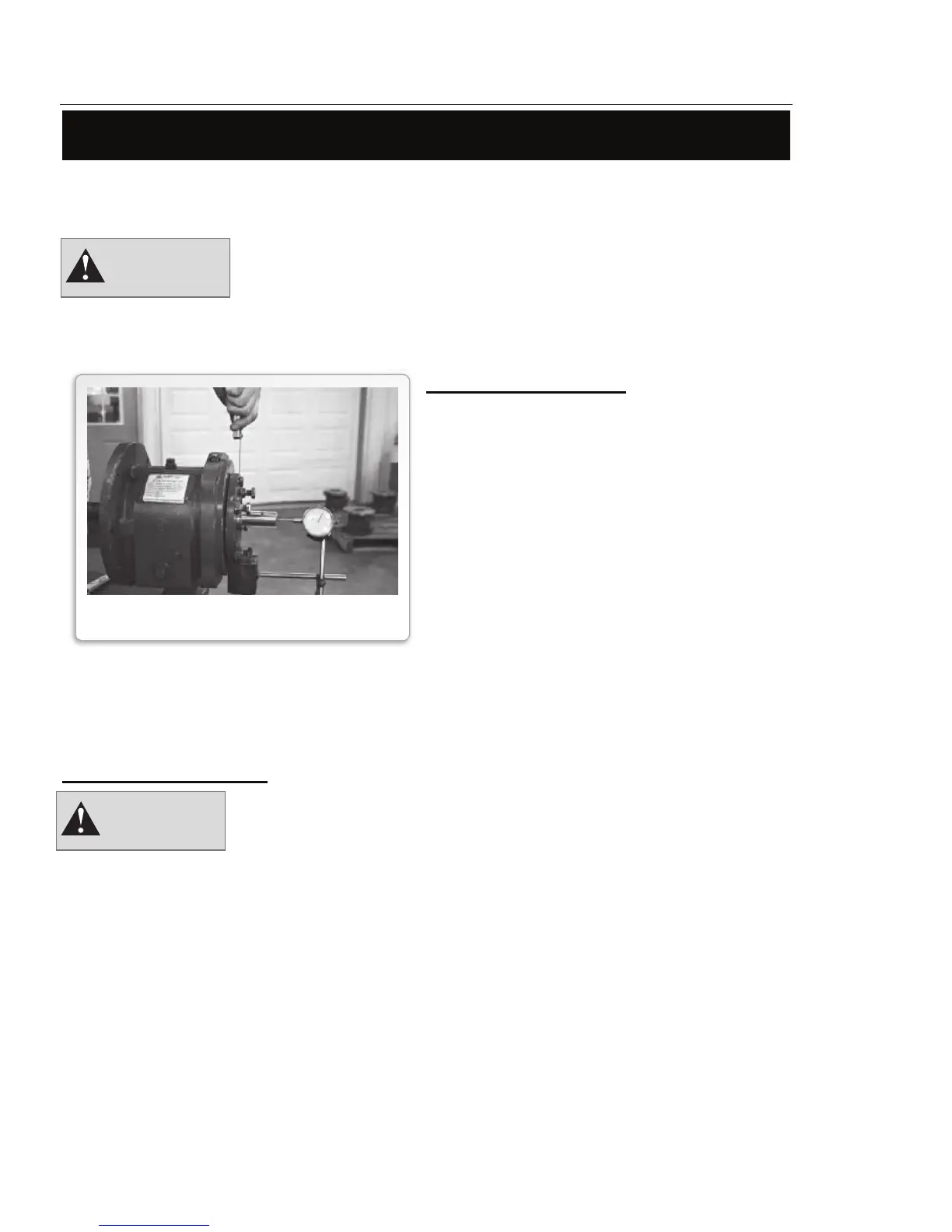

Dial Indicator Method

1. Lock out power supply to motor.

2. Remove coupling guard and coupling spacer.

3.

Place a dial indicator with a magnetic mounting base on the surface of the pump baseplate. Position

indicator against face of pump shaft.

4. Loosen jacking bolts (370D) and jam nuts (423).

5. Tighten bearing housing bolts (370C) evenly, while slowly rotating the shaft until the

impeller just starts to rub on the casing. Set dial indicator to zero.

6. Tighten the jacking bolts (370D) evenly, until they contact the bearing frame. Continue to

tighten the jacking bolts evenly, about one flat at a time, drawing the bearing housing away

from the frame until

the dial indicator shows the proper clearance

APPENDIX - I

Feeler Gauge Method

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Appendix Page 42

Use non-foaming and non-detergent oils only.

Recommended Lubricants

Lubricating Oil Requirements

Pumpage temperature

< 350

0

F

Pumpage temperature

> 350

0

F

ISO Grade VG 68 VG 100

Approx. SSU @ 100

0

F 300 470

DIN 51517 C68 C100

Kinematic Viscosity @100

0

F

mm

2

/sec

68 100

Some acceptable lubricating oils:

Chevron GTS Oil 68

Exxon TERRESTIC 68 or NUTO H68

Mobil DTE Heavy-Medium

Philips Mangus 315

Shell Tellus Oil 68

Sunoco Sunvis 968

Amoco Amoco Industrial #68

Royal Purple SYNFILM ISO VG68

Change oil after 200 hours of initial operation, then every 2000 hours or three (3) months

thereafter, whichever occurs first.

Bearing Frame Oil Capacity

Frame Pints

S 1.0

M 2.6

L 3.0

XL 7.4

Capacities are approximate. Do not over fill the oil sump as this will cause overheating and

damage the bearings. Fill to the centerline of the sight glass.

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Appendix Page 42

Use non-foaming and non-detergent oils only.

Recommended Lubricants

Lubricating Oil Requirements

Pumpage temperature

< 350

0

F

Pumpage temperature

> 350

0

F

ISO Grade VG 68 VG 100

Approx. SSU @ 100

0

F 300 470

DIN 51517 C68 C100

Kinematic Viscosity @100

0

F

mm

2

/sec

68 100

Some acceptable lubricating oils:

Chevron GTS Oil 68

Exxon TERRESTIC 68 or NUTO H68

Mobil DTE Heavy-Medium

Philips Mangus 315

Shell Tellus Oil 68

Sunoco Sunvis 968

Amoco Amoco Industrial #68

Royal Purple SYNFILM ISO VG68

Change oil after 200 hours of initial operation, then every 2000 hours or three (3) months

thereafter, whichever occurs first.

Bearing Frame Oil Capacity

Frame Pints

S 1.0

M 2.6

L 3.0

XL 7.4

Capacities are approximate. Do not over fill the oil sump as this will cause overheating and

damage the bearings. Fill to the centerline of the sight glass.

WARNING

WARNING

FIGURE A-1

FEELER GAUGE METHOD

Loading...

Loading...