GRISWOLD PUMP COMPANY Installation Page 6

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Installation Page 8

Installation

The pump location should be clean, well ventilated, properly drained and allow room for

maintenance and inspection.

Trouble-free operation of a pump begins with proper installation with particular attention being

paid to the baseplate and piping attachments. A secure baseplate will enable accurate alignment

to be attained and maintained. Flange loads from misaligned or improperly supported piping

will make alignment difficult and will cause premature failures.

Baseplates and Anchors

The preferred mounting for a baseplate is on a concrete pad with grouting. No matter how robust

its design, there is always some flexibility in the baseplate itself. If there is insufficient support

under the baseplate, it can distort causing alignment difficulties and normal vibrations can be

amplified to unacceptable levels through resonances in the pump support and/or piping. A

properly grouted baseplate will resist distortion and will provide sufficient mass to dampen any

vibration.

Anchor (foundation) bolts are used to hold the baseplate to its support structure, whatever that

may be. In the preferred case of mounting the pump unit on a concrete pad, the anchor bolts are

set into the pad as indicated in the following illustration. When pouring the pad, it’s helpful to

have a wooden template attached to the foundation form to position the anchor bolts at their

locations as indicated on the pump unit assembly drawing.

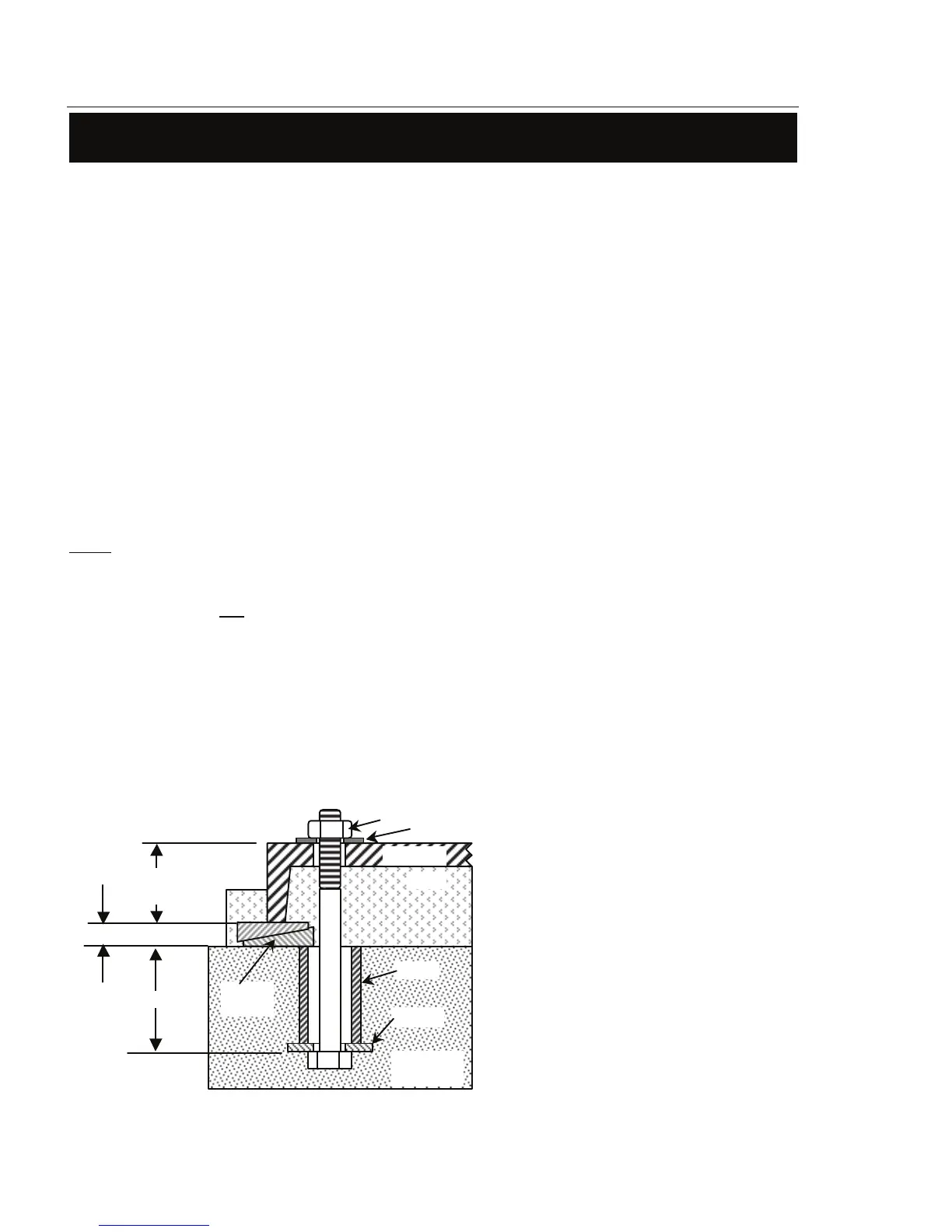

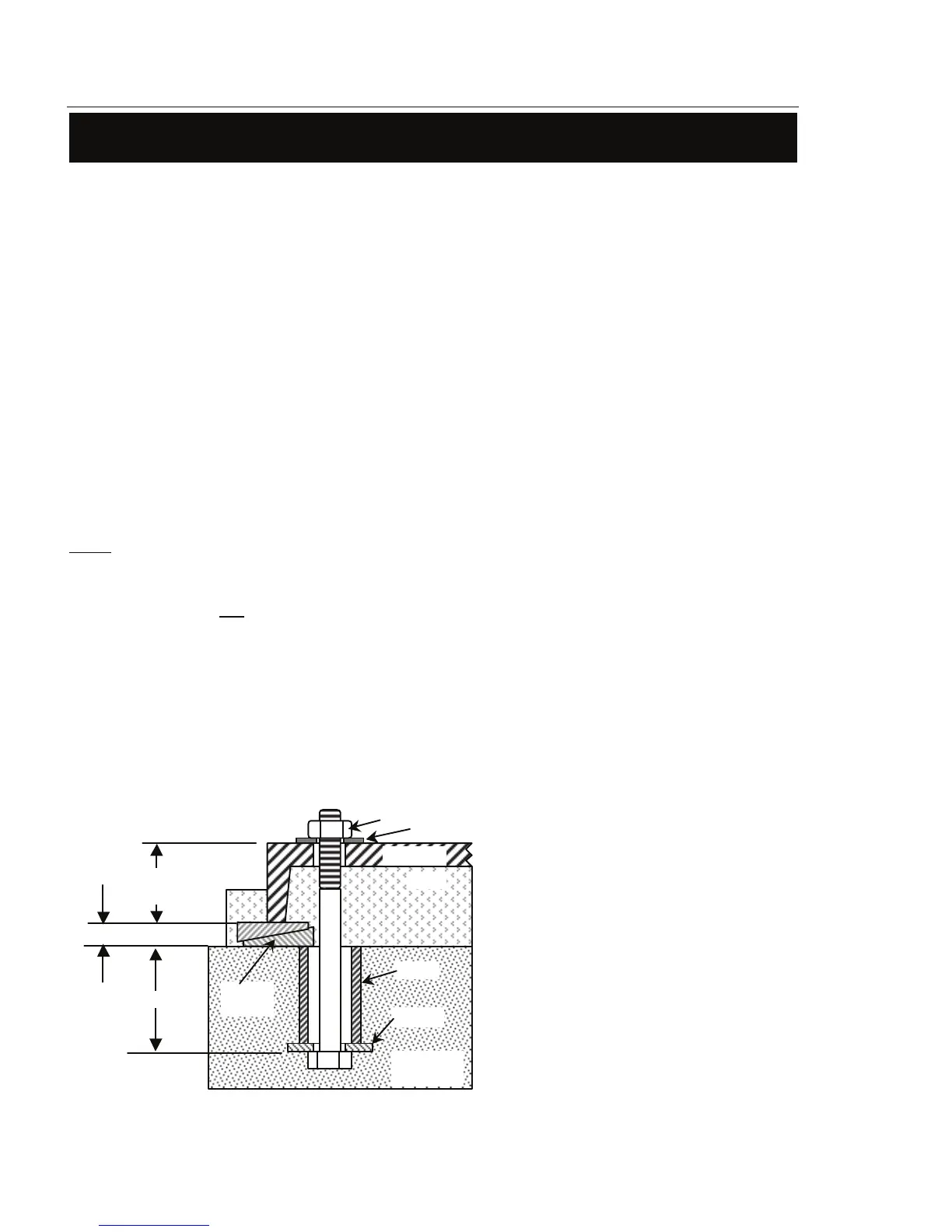

Typical Anchor Bolt (Sleeve Type)

Baseplate

Grout

Sleeve

Washer

Washer

Nut

Drawing

12" - 18"

Wedges

Anchor bolts are usually sized

than the anchor bolt hole size in the base.

Calculate bolt length as indicated in

Figure 4 at the left.

The ID of the sleeve should be two bolt

sizes larger than the anchor bolt.

- 1½" space between

the bottom edge of the baseplate and the

A “Sleeve” type anchor bolt is shown

here. Alternatively, a “hook” or “J” type

anchor bolt may be used.

Pack the space between the anchor bolt

and sleeve to prevent concrete and/or

grout from entering this area.

When pumps and motors are assembled on a baseplate at the factory, a preliminary

alignment is done to ensure that the pump and motor can be aligned at its installation.

This alignment is not to be considered as a final alignment. The factory alignment can,

and does, change during shipment and when the pumping unit is installed. Actually,

several alignments are necessary as will be described later.

Loading...

Loading...