GRISWOLD PUMP COMPANY Installation Page 14

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Installation Page 16

Severe damage can be done to the pump if it is driven in reverse rotation.

During installation, when the motor is jogged to check rotation,

this MUST be done with the coupling spacer removed.

Do not install coupling spacer until correct motor rotation has been established

Operators must become familiar with the installation and service manual as supplied by the

engine manufacturer.

Drivers

Electric Motors

Connect power supply in conformance with local and national codes. Line voltage and wire

capacity must match the ratings stamped on the motor nameplate.

Engine-Drives

Safe and efficient operation of a pumping unit driven by an engine, whether diesel or gasoline

requires the installation to satisfy the following requirements:

1. Be well ventilated in order to keep the ambient temperature as low as possible.

2. Provide ample air for proper combustion.

3. Provide the engine with an efficient exhaust system so that the combustion gases

discharge with a minimum of backpressure.

4. Provide for a fuel system of adequate capacity, which meets the local codes.

5. Provide ample accessibility to service engine.

6. Provide engines / drives for correct rotation of the pump. Engine rotation is determined at

the factory. No change of engine rotation can be made in the field.

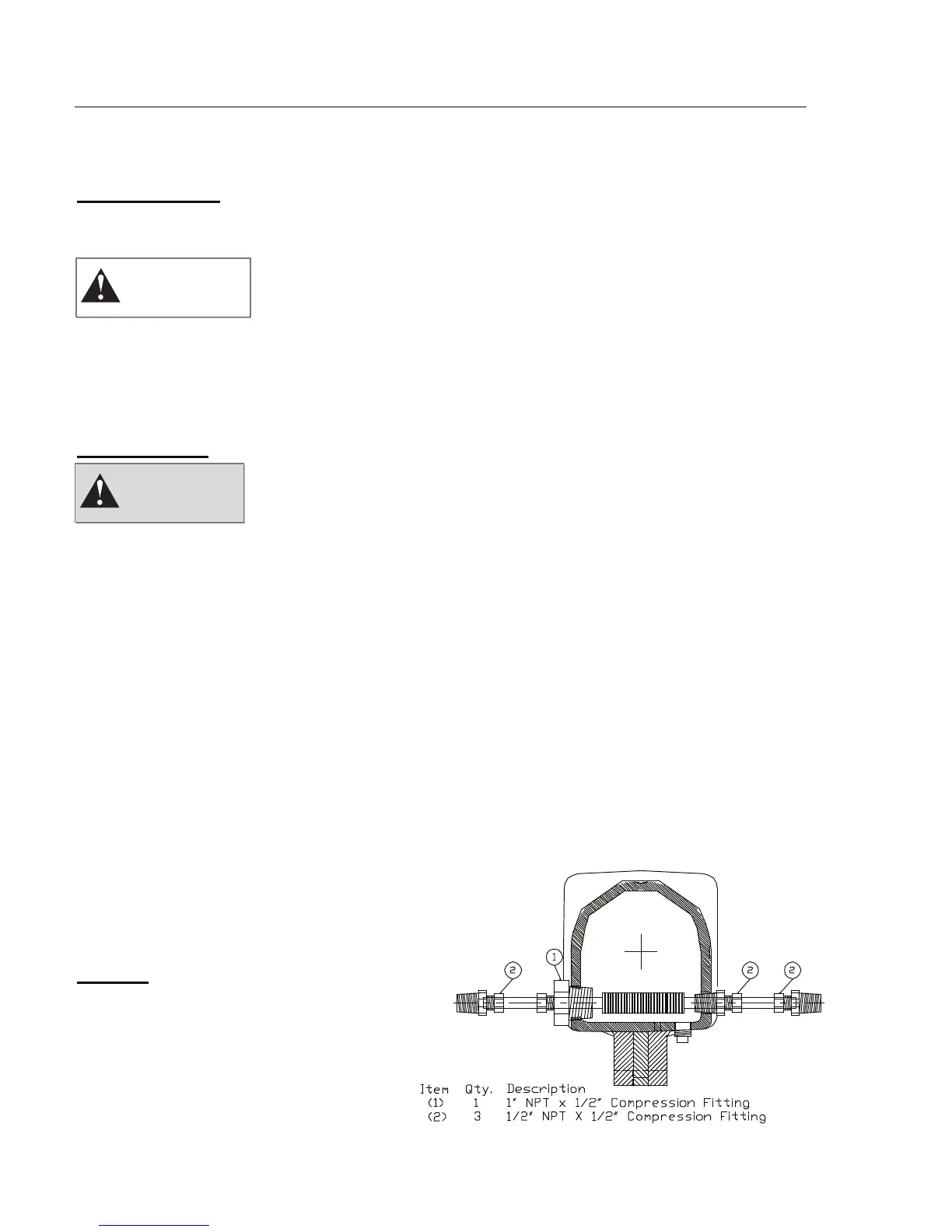

Flushing and Cooling Lines

Pump auxiliaries such as flushing and

cooling are application-specific. In

general, however, note the following:

Cooling

Bearing cooling is required for applications

with pumpage temperature above 350

0

F or

if bearings operate above approx. 180

0

F.

Bearing cooling is accomplished with a

finned-tube cooler,

WARNING

CAUTION

Loading...

Loading...