GRISWOLD PUMP COMPANY Appendix Page 39

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Appendix Page 41

7. Tighten bearing housing bolts (370C) evenly, and then tighten jacking bolts (370D) evenly.

Make sure dial indicator reading does not move from the proper setting. Rotate shaft to make

sure that it turns freely.

8. Reinstall coupling spacer and coupling guard.

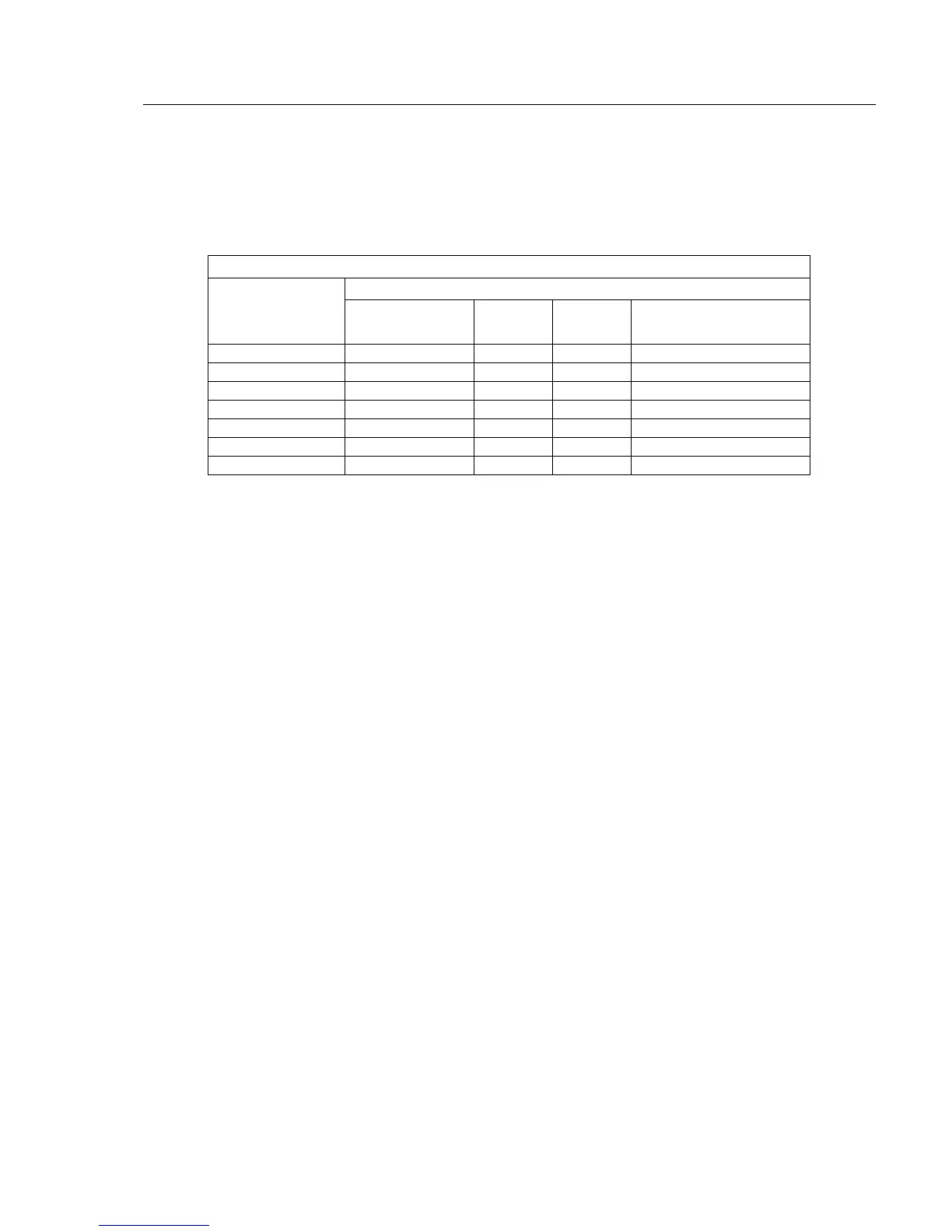

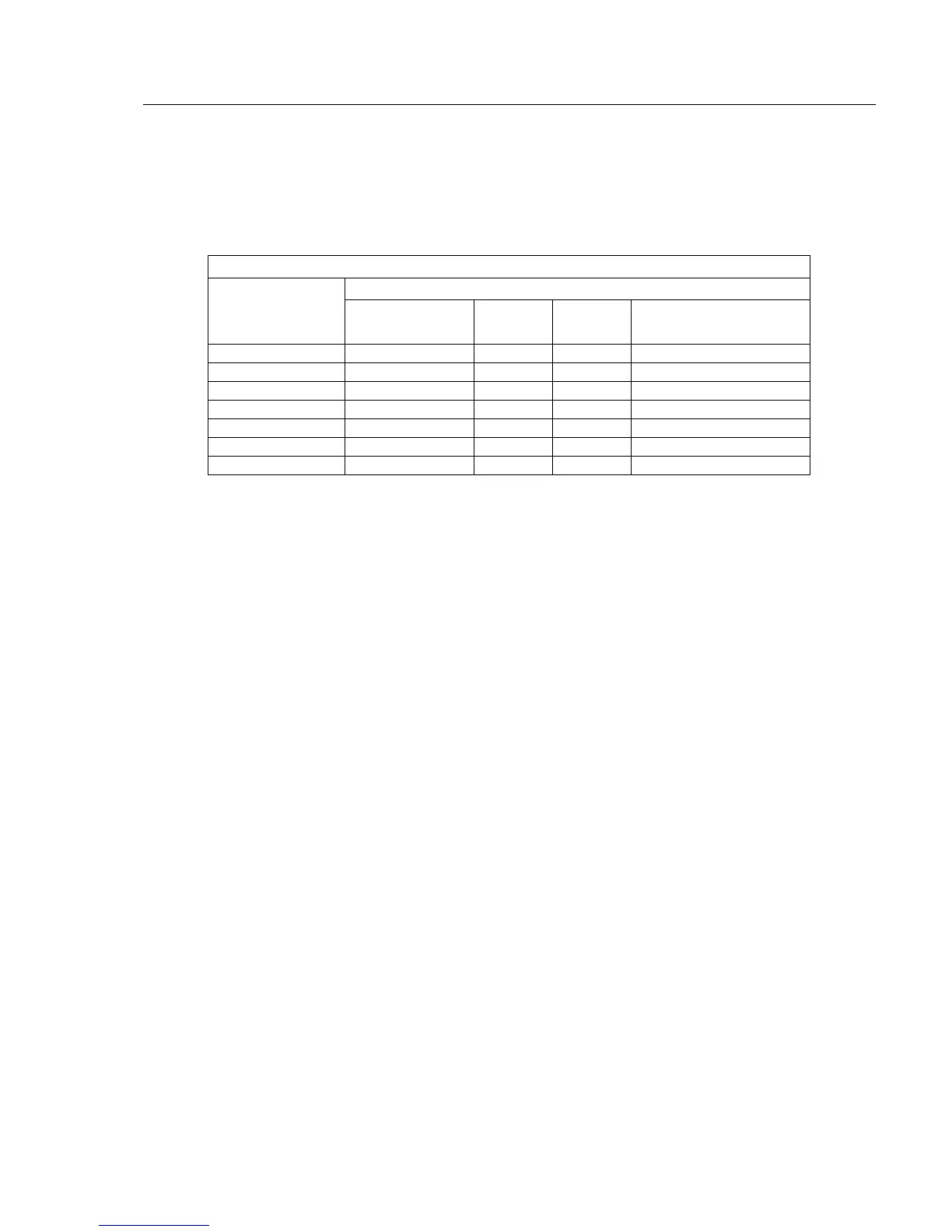

Table 3

Impeller Clearance at Ambient for Various Service Temperatures, inches

Pump Frame Size Pumpage

Temperature

S M, L Low

Flow

XL

-20

0

to 200

0

F 0.005" 0.008" .018” 0.015"

Up to 250

0

F 0.006" 0.009" .019” 0.016"

Up to 300

0

F 0.007" 0.010" .020” 0.017"

Up to 350

0

F 0.009" 0.012" .022” 0.019"

Up to 400

0

F 0.010" 0.013" .023” 0.020"

Up to 450

0

F 0.011" 0.014" .024” 0.021"

Up to 500

0

F 0.012" 0.015" .025” 0.022"

Loading...

Loading...