GRISWOLD PUMP COMPANY Installation Page 11

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Installation Page 13

In any case, disregard the coupling manufacturer’s published misalignment limits, as these

will impose unacceptable loads on the pump and motor shafts and bearings.

Alignment is done with the coupling spacer removed.

Since any misalignment will impose loads on the pump and driver shafts, the objective is to

minimize any misalignment in order to protect the pump and driver and minimize any tendency

for vibration. Suggested misalignment limits are:

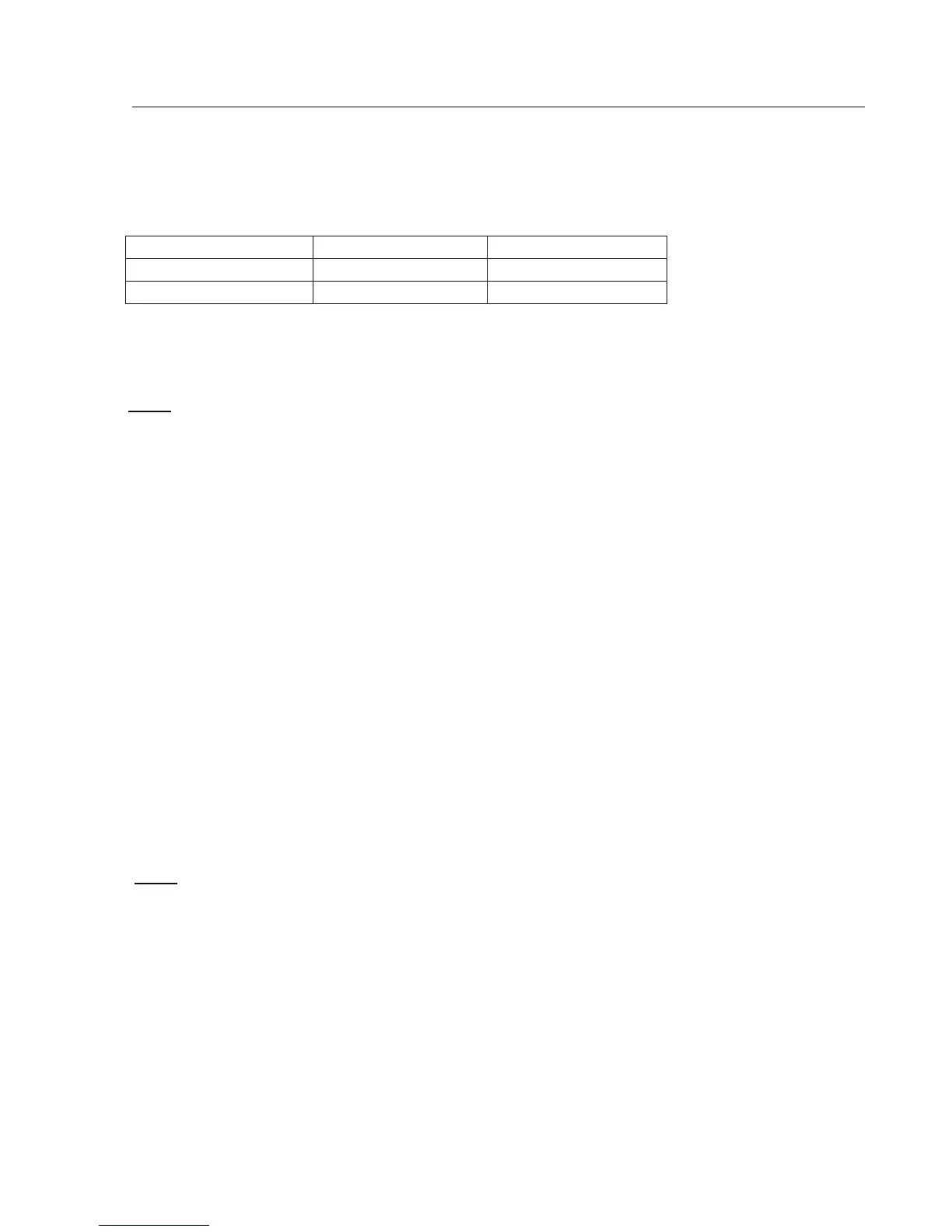

Pump Frame Group Max. Parallel Max. Angular

S, M, L 0.005" 0.005"

XL 0.010" 0.010"

For optimum performance and Mean Time Between Pump Maintenance (MTBPM), use

alignment limits half of those shown above.

Alignment must be done at several different times:

1. Prior to grouting baseplate during installation

2. After grouting baseplate and tightening anchor bolts

3. After attaching suction and discharge piping prior to initial operation

4. Hot alignment after equipment temperatures have stabilized

5. After pump maintenance if back pull-out assemblies are removed

Since the Model 811 pump is foot-mounted, its shaft centerline will rise when handling pumpage

at elevated temperatures. Similarly, the motor shaft centerline will rise as it reaches its operating

temperature. Therefore, we will often purposely mis-align shafts vertically during cold

alignment to allow for thermal growth, thus bringing the shafts into alignment at operating

temperature. This is shown in Table 2 on Page 15.

The Griswold Model 811 is an ANSI B73.1 Process Pump and is, therefore, furnished with a

spacer coupling to enable removal of the back pull-out assembly without disturbing the casing or

moving the motor driver.

The most simple alignment check is with a straight edge and calipers or inside micrometer. This

method is the least accurate, but it will serve if a dial indicator or laser is not available.

Table 1

Loading...

Loading...