GRISWOLD PUMP COMPANY Repair Maintenance Page 24

Installation, Operation and Maintenance Manual

Griswold Model 811

Griswold Pump Company Repair Maintenance Page 26

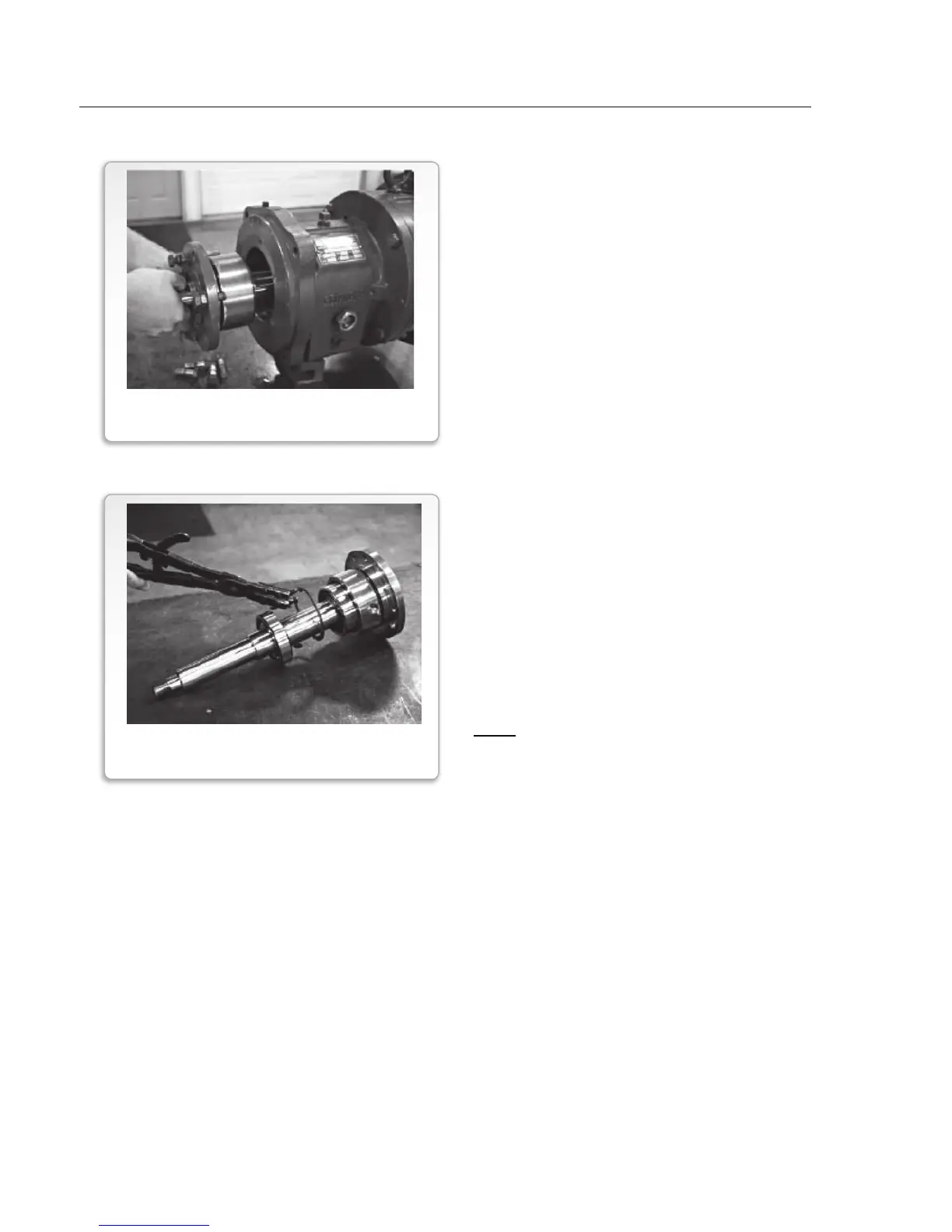

When pressing bearings off shaft, use force

on inner race only.

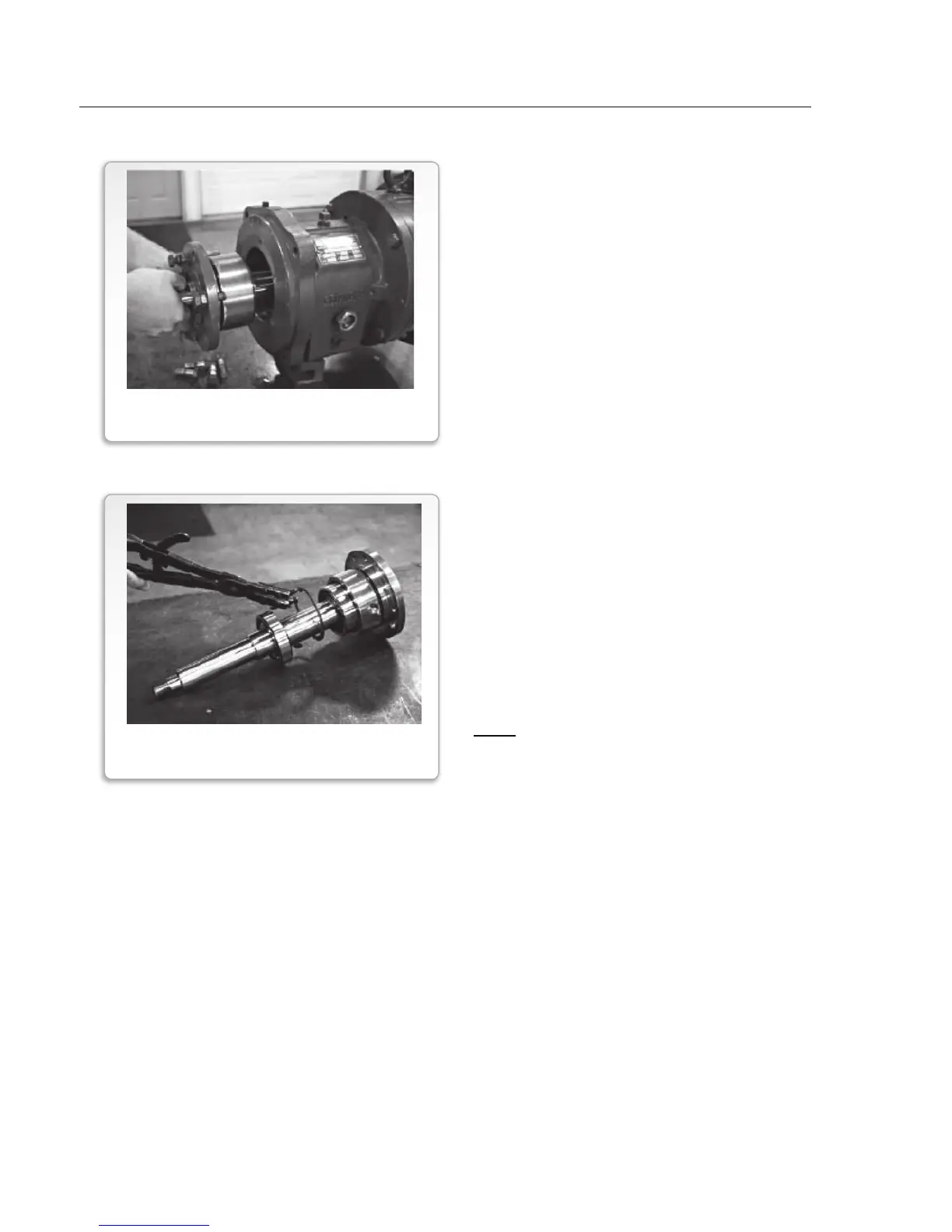

Power End Disassembly – S and M Group Pumps

1. Remove cap screws (Item 370C),

loosen jam nuts (Item 423).

2. Tighten jack bolts (Item 370D) evenly.

Bearing housing will begin to back out of

frame.

3. Slide shaft assembly, with bearing

housing out of bearing frame.

4. Remove all jackscrews and nuts (Item

370D) and (Item 423).

5. Remove and discard bearing housing o-

ring (Item 496).

6. Using snap ring pliers, remove bearing

retaining ring (Item 361A).

7. Remove bearing housing (Item 134)

from shaft by tapping the shaft with a

rubber mallet, driving the thrust

bearings and shaft assembly through

the housing. Do not remove lab seal.

8. Remove bearing lock nut (Item 136)

and lock washer (Item 382).

9. Using an arbor press, remove inboard

and outboard bearings. Slide snap ring off shaft after bearings have been removed.

10. Complete disassembly of bearing frame if required. Remove oil fill plug (113A), oil

sight glass (408N) and (4) oil mist/grease plugs (408H). Remove oil cooler inlet and

outlet plugs (408L) and (408M). On M models, remove frame foot attachment bolts

(370F).

FIGURE 17

BEARING REMOVAL

FIGURE 16

SHAFT/BEARING HOUSING REMOVAL

Loading...

Loading...