G0603X 25" Extreme Series Planer

-37-

Table Parallelism Adjustments

The table is adjusted by turning the elevation

screw housing brackets underneath the table.

To adjust the table parallelism:

1. Adjust the table height so that the Rotacator

(or wood block and feeler gauges) can be

used.

2. DISCONNECT THE PLANER FROM

POWER!

3. Raise the headstock cover.

4. Using the cutterhead pulley, rotate the

cutterhead so that the carbide insert on the

left edge of the cutterhead is at bottom dead

center (BDC) (see

Figure 29)—this will also

place the carbide insert on the right side of

the cutterhead at BDC.

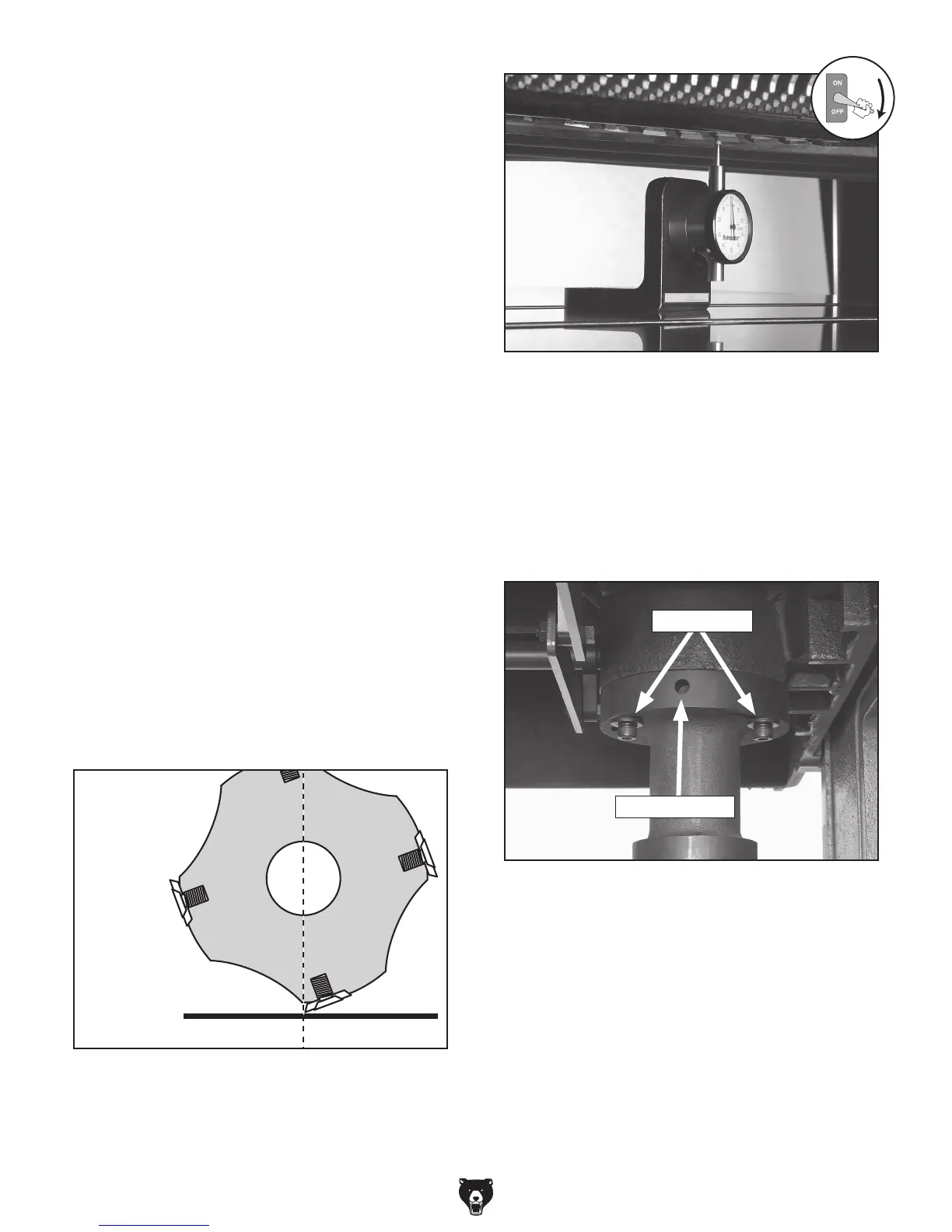

—If you are using a Rotacator, find BDC of

the carbide insert by slowly rocking the

cutterhead pulley back and forth, and set

the Rotacator dial to zero (see

Figure 30).

—If a Rotacator is not available, use a wood

block and a feeler gauge; then, slowly rock

the cutterhead pulley back and forth so

the carbide insert just makes contact as it

passes the feeler gauge.

Figure 29. Cutterhead carbide insert at bottom

dead center (BDC).

5. Determine which side of the table you will

adjust to bring the table parallel with the

cutterhead (within

0.003").

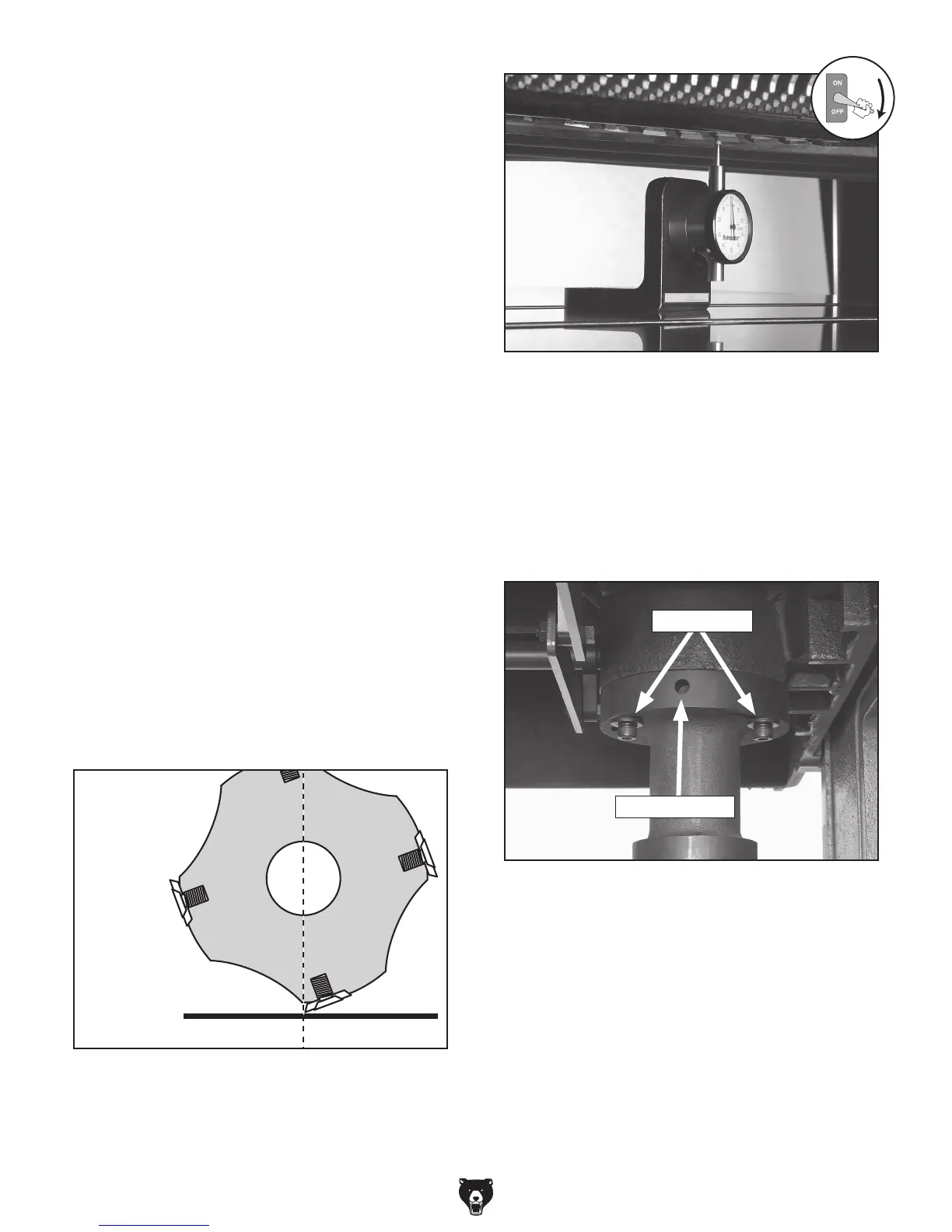

6. Use the 6mm hex wrench to loosen the table

elevation housing bracket cap screws (under

-

neath the table) for that side of the table (see

Figure 31).

7. Insert the long end of the 10mm hex wrench

into the leverage hole and turn the bracket

until you are satisfied with the table parallel

-

ism from side-to-side.

Note: The slight deformation of the rubber

elevation screw cover is normal and will not

affect table movement.

8. Retighten the cap screws holding the bracket

in place.

Figure 30. Finding BDC with the Rotacator.

Figure 31. Table elevation screw housing

bracket.

Leverage Hole

Cap Screws

Loading...

Loading...