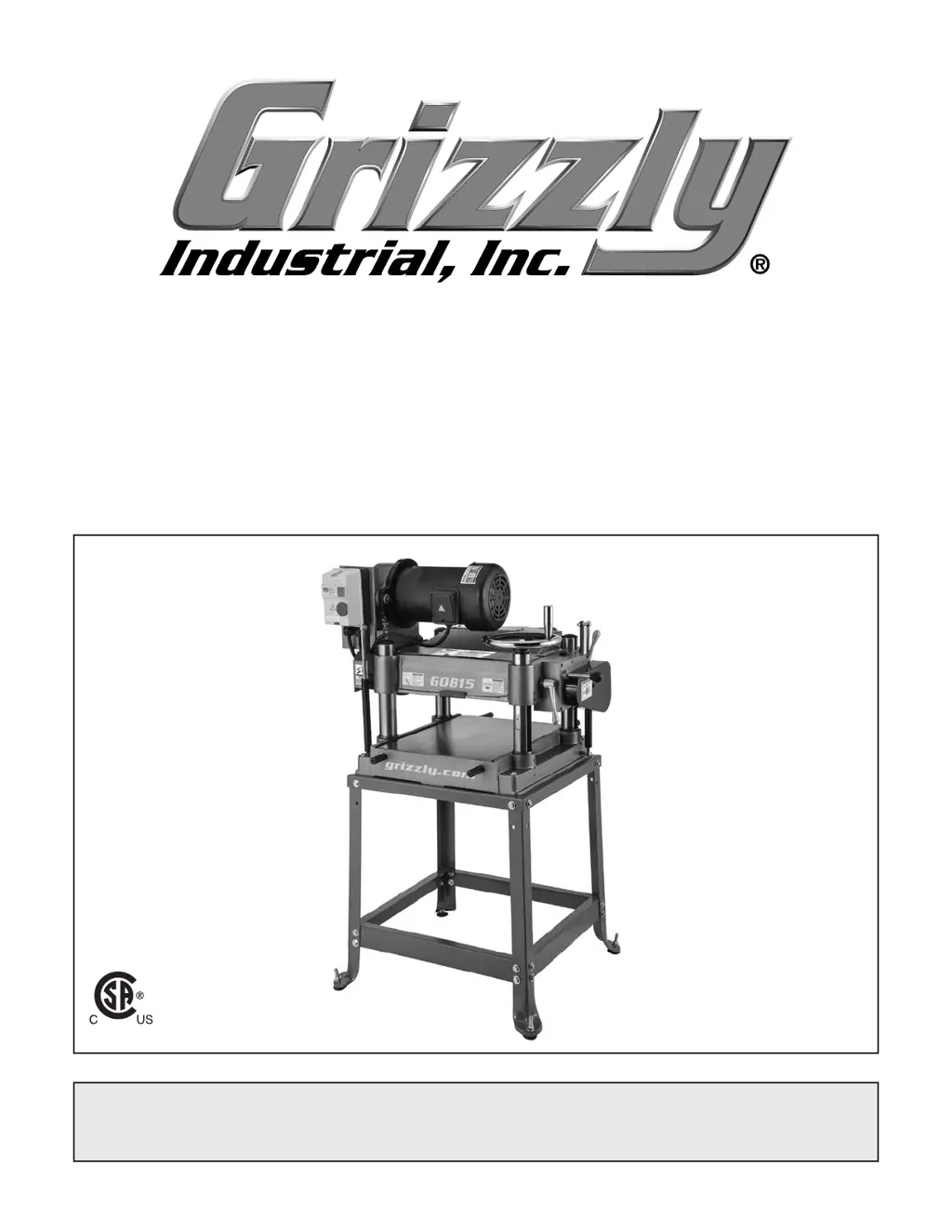

Why does my Grizzly G0815 Planer leave uneven cutting marks or chatter marks?

- NnjohnsonAug 15, 2025

Uneven cutting marks, a wavy surface, or chatter marks on your board can occur for several reasons: * The feed rate might be too fast, so try slowing it down. * The chipbreaker could be set unevenly or not low enough; adjust its height. * The knives might not be installed evenly in the cutterhead; use a knife-setting gauge to adjust them. * The cutterhead bearings could be worn, requiring replacement.