How to fix excessive snipe on a Grizzly G0505 Planer?

- LLindsay KimAug 12, 2025

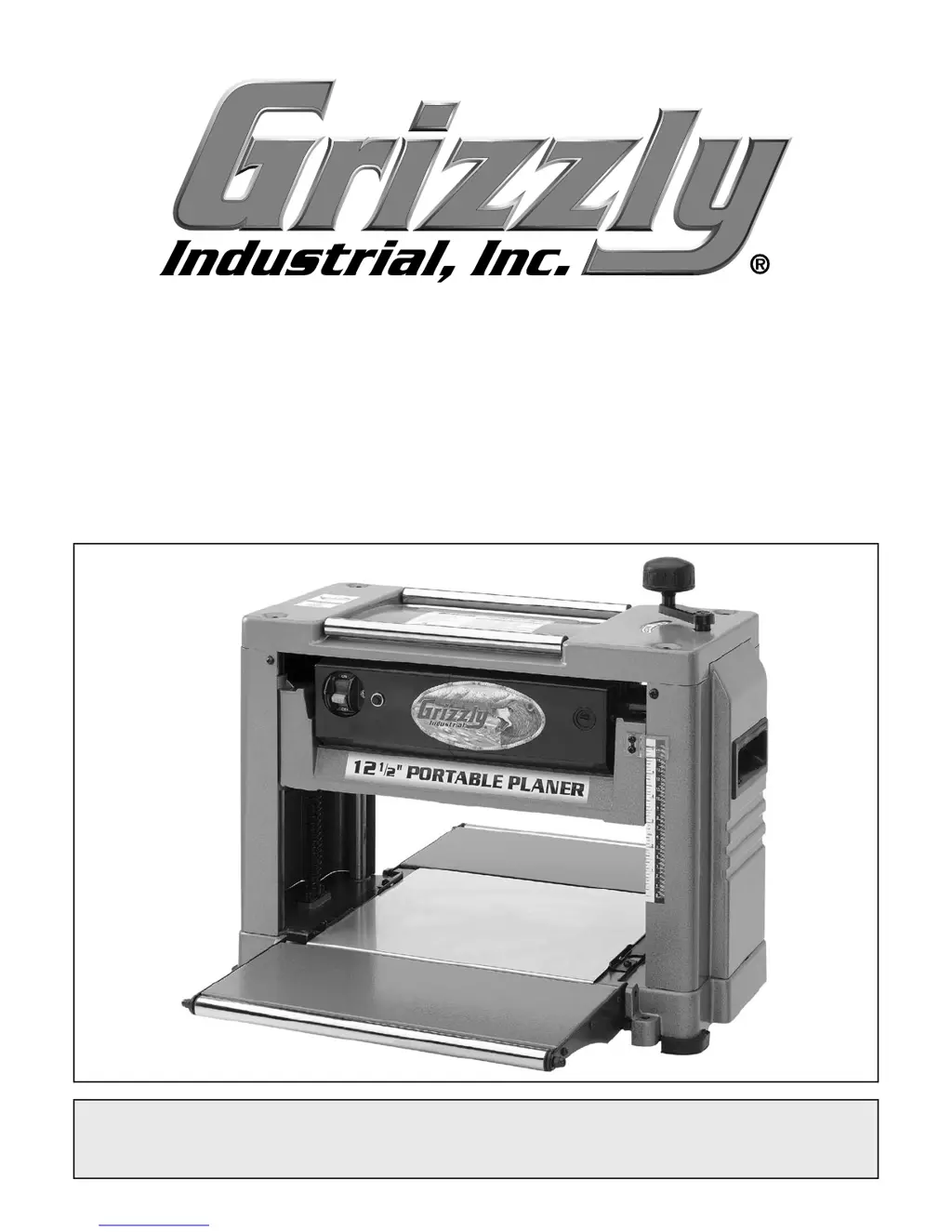

If your Grizzly Planer produces excessive snipe, resulting in a gouge at the end of the workpiece, it might be due to the outfeed extension wing sloping down or not being level with the table. You can adjust the outfeed extension wing to fix this. Another possible cause is that the workpiece isn't supported as it exits the planer. To remedy this, get assistance or use support accessories to properly support the workpiece.