Model G0758 (Mfd. Since 2/14)

-29-

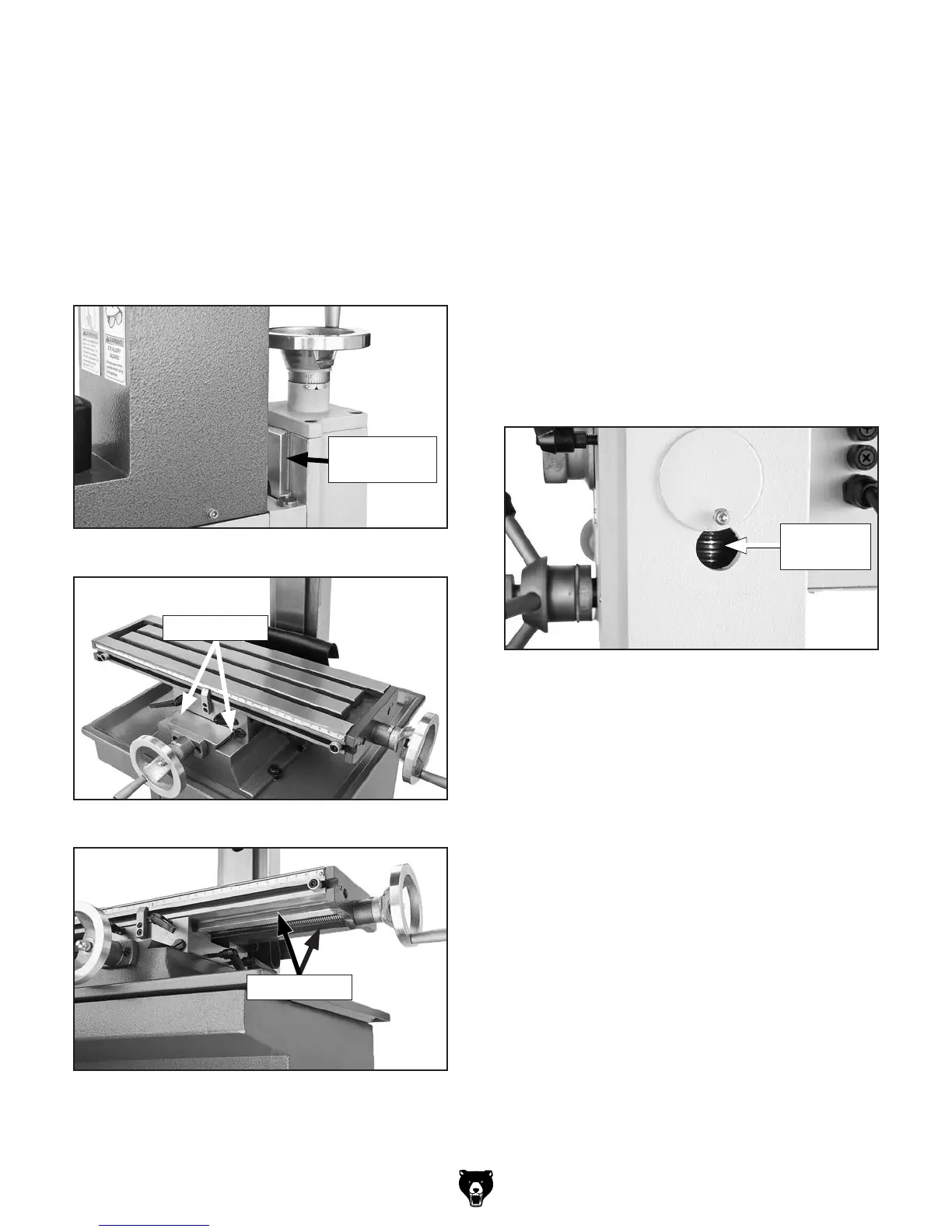

Table and Column Ways

Lube Type . . Model SB1365 or ISO 68 Equivalent

Lube Amount ........................................Thin Coat

Lubrication Frequency ........... 8 hrs. of Operation

Regular lubrication will ensure mill/drill performs

at its highest potential. Regularly wipe table and

column ways with recommended lubrication, then

move components back and forth several times to

ensure smooth movements (see Figures 34–36).

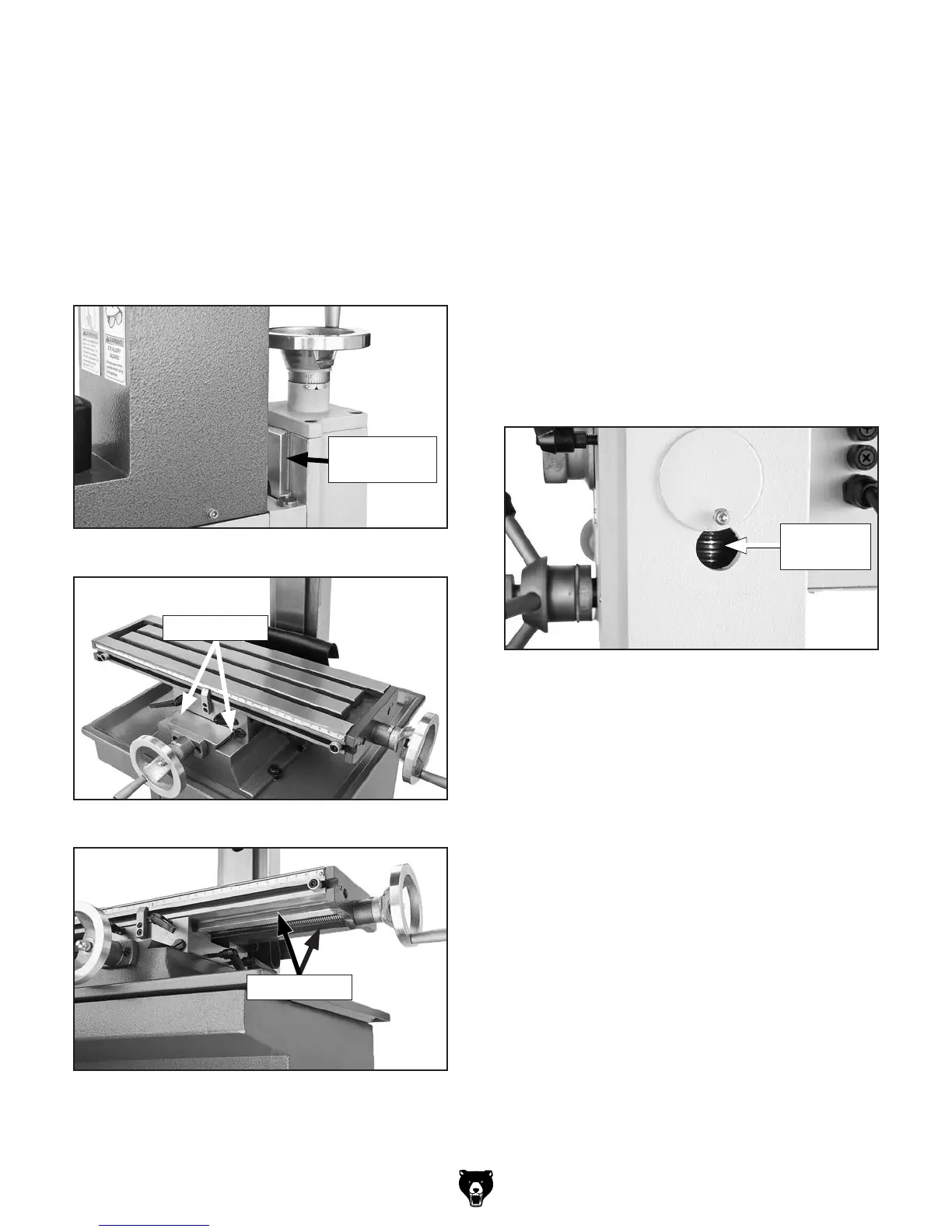

Z-Axis Leadscrews

Lube Type . . Model T23964 or NLGI#2 Equivalent

Lube Amount ........................................Thin Coat

Lubrication Frequency ....... 120 hrs. of Operation

To lubricate Z-axis leadscrew:

1. DISCONNECT MACHINE FROM POWER!

2. Lower headstock as far as you can without

contacting spindle to table surface.

3. Use mineral spirits and a brush to clean as

much existing grease and debris off of Z-axis

leadscrew shown in Figure 37 as possible.

Allow leadscrew to dry.

4. Using a brush, apply NLGI#2 grease to

exposed leadscrew threads, then move head-

stock through its full range of motion several

times to disperse grease along full length of

leadscrew.

Figure 35. Y-axis way lubrication points.

Y-Axis Ways

Figure 36. X-axis lubrication points.

X-Axis Ways

Figure 37. Z-axis leadscrew lubrication point.

Z-Axis

Leadscrew

Figure 34. Z-axis way lubrication points.

Z-Axis Ways

(1 of 2)

Loading...

Loading...